Preparation device and preparation method for preparing desulfurizer through deep purification treatment of carbide slag

A technology for deep purification and preparation of devices, applied in chemical instruments and methods, grain processing, chemical/physical processes, etc. Convenience and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

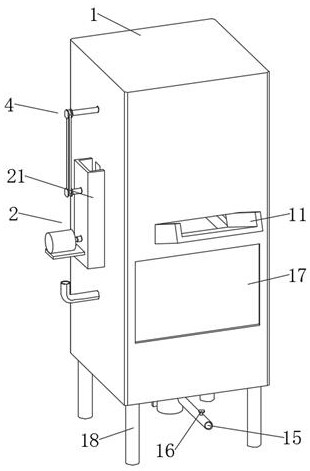

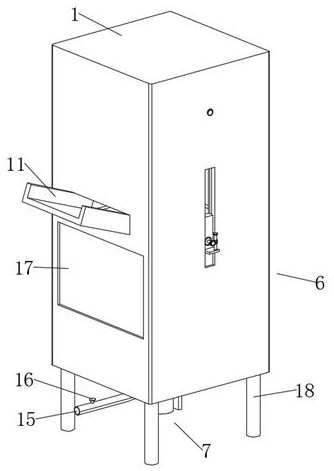

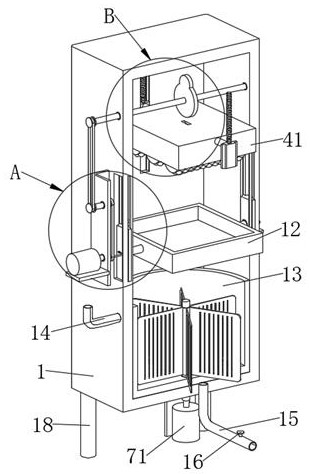

[0037] Example: such as Figure 1-9 As shown, the present invention provides a preparation device for preparing a desulfurizer by advanced purification treatment of calcium carbide slag, comprising a preparation box 1, a feed hopper 11 is fixedly installed on one side of the preparation box 1, and a material box 12 is arranged inside the preparation box 1. Through the feed hopper 11, block lime can be conveniently added to the inside of the material box 12. The inside of the preparation box 1 is fixedly equipped with a preparation bucket 13, and the other side of the preparation box 1 is fixedly installed with a feed pipe 14. The feed pipe 14 can conveniently add water and water solvent to the inside of the preparation barrel 13, one end of the feed pipe 14 runs through the preparation barrel 13 and is fixedly connected to the preparation barrel 13, and the bottom end of the preparation barrel 13 is fixedly equipped with a discharge pipe 15 , the discharge pipe 15 can discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com