Modification method of basalt fiber in basalt fiber sprayed concrete for tunnel

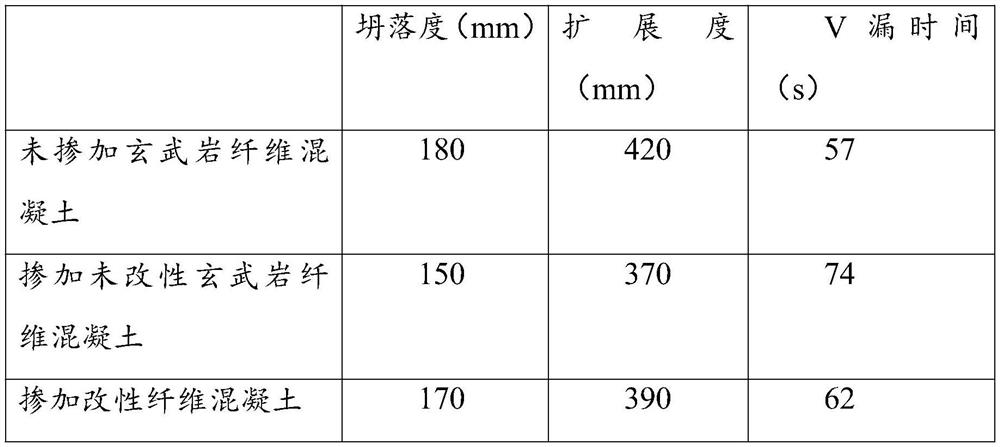

A technology of basalt fiber and shotcrete, which is applied in the field of basalt fiber, can solve the problems of reducing the rebound rate of shotcrete, poor concrete fluidity, and reduced concrete fluidity, so as to enhance antistatic ability, enhance dispersion, and improve dispersion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The modification method of the basalt fiber in the basalt fiber sprayed concrete for the tunnel of the present embodiment comprises the following steps:

[0048] Step 1: Heat the basalt fiber in an oven at 250°C for 2 hours, then soak it in acetone solution for 2 hours after cooling, take it out, rinse it with tap water several times until it is clean, and then dry it in the natural environment;

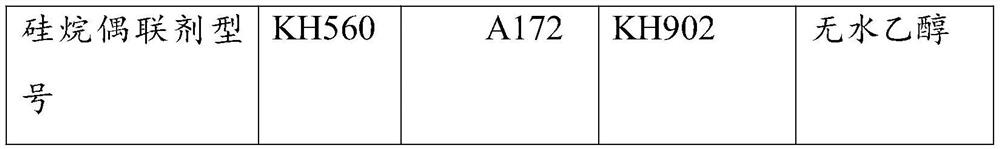

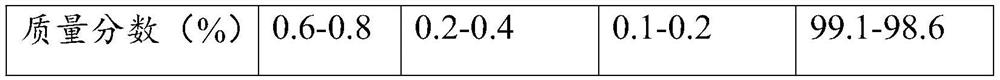

[0049] Step 2: soak it in silane coupling agent-absolute ethanol solution for 1 hour after drying, take it out, and then heat it in an oven at 120°C for 1 hour to make the basalt fiber and silane coupling agent completely react, and then use it after cooling .

[0050] In Step 2 of this embodiment, basalt fibers are used for heat improvement treatment before soaking in the silane coupling agent-absolute ethanol solution, and then placed in the surface modification solution for treatment.

[0051] The specific operation method of the thermal improvement treatment of the presen...

Embodiment 2

[0062] The modification method of the basalt fiber in the basalt fiber sprayed concrete for the tunnel of the present embodiment comprises the following steps:

[0063] Step 1: Heat the basalt fiber in an oven at 250°C for 2 hours, then soak it in acetone solution for 2 hours after cooling, take it out, rinse it with tap water several times until it is clean, and then dry it in the natural environment;

[0064] Step 2: soak it in silane coupling agent-absolute ethanol solution for 1 hour after drying, take it out, and then heat it in an oven at 120°C for 1 hour to make the basalt fiber and silane coupling agent completely react, and then use it after cooling .

[0065] In Step 2 of this embodiment, basalt fibers are used for heat improvement treatment before soaking in the silane coupling agent-absolute ethanol solution, and then placed in the surface modification solution for treatment.

[0066] The specific operation method of the thermal improvement treatment of the presen...

Embodiment 3

[0077] The modification method of the basalt fiber in the basalt fiber sprayed concrete for the tunnel of the present embodiment comprises the following steps:

[0078] Step 1: Heat the basalt fiber in an oven at 250°C for 2 hours, then soak it in acetone solution for 2 hours after cooling, take it out, rinse it with tap water several times until it is clean, and then dry it in the natural environment;

[0079] Step 2: soak it in silane coupling agent-absolute ethanol solution for 1 hour after drying, take it out, and then heat it in an oven at 120°C for 1 hour to make the basalt fiber and silane coupling agent completely react, and then use it after cooling .

[0080] In Step 2 of this embodiment, basalt fibers are used for heat improvement treatment before soaking in the silane coupling agent-absolute ethanol solution, and then placed in the surface modification solution for treatment.

[0081] The specific operation method of the thermal improvement treatment of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com