Method and system for preparing 1, 4-butanediol and co-producing 1, 4-butenediol through hydrogenation of 1, 4-butynediol

A technology of butynediol and butenediol, applied in the field of hydrogenation of 1,4-butynediol, which can solve the problems of large power consumption, increased cost, and low selectivity of 1,4-butenediol , to achieve the effect of large operation flexibility, wide application range and full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

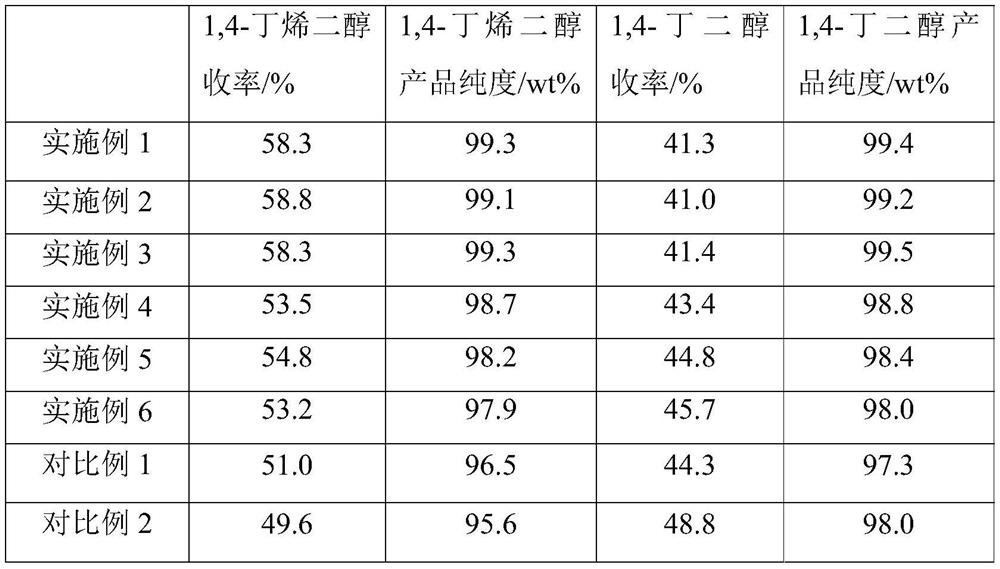

Embodiment 1

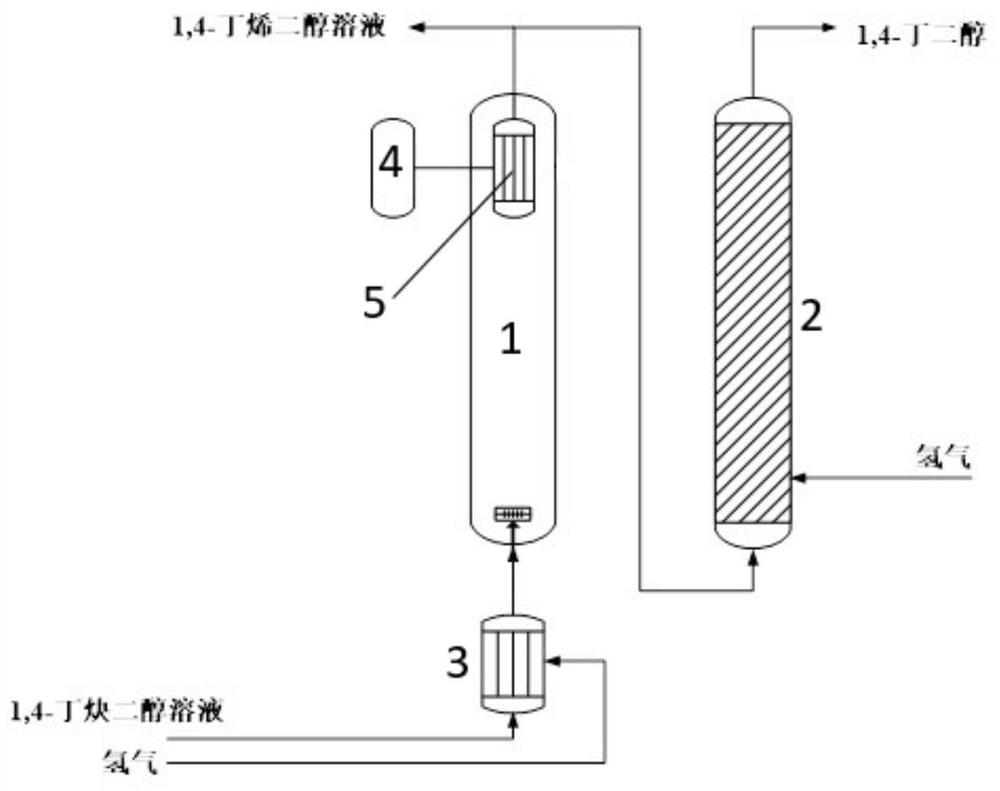

[0072] Using the disclosed system to hydrogenate 1,4-butynediol aqueous solution to prepare 1,4-butanediol and co-produce 1,4-butenediol, the process flow is as follows figure 1 As shown, it consists of a fluidized bed reactor 1 and a fixed bed reactor 2 two-stage hydrogenation process.

[0073] The 1,4-butynediol aqueous solution with a concentration of 35% by weight and a pH of 11 enters the tube-side membrane tube assembly 3 through the liquid inlet at the bottom of the gas-liquid mixer, and the estimated hydrogen gas passes through the gas on the gas-liquid mixer shell. The inlet enters the shell side, and the hydrogen gas is dispersed into microbubbles through the micropores on the membrane tube wall with an average pore size of 3.0 μm, and is fully mixed with the 1,4-butynediol aqueous solution in the tube side of the gas-liquid mixer to obtain a mixed reactant , where the pressure difference on both sides of the membrane hole of the membrane tube assembly 3 is 0.1Mpa, a...

Embodiment 2

[0077] The method of Example 1 is used to hydrogenate the 1,4-butynediol aqueous solution to prepare 1,4-butanediol and co-produce 1,4-butenediol, the only difference is:

[0078] The parameters of the hydrogenation reaction are: (1) the temperature of the primary hydrogenation reaction is 50°C, and the hydrogenation pressure is 2.0MPa; the temperature of the secondary hydrogenation reaction is 100°C, and the hydrogenation pressure is 4.0MPa; , the gravimetric space velocity of 4-butynediol aqueous solution is 10h -1 , the weight space velocity of the first hydrogenation reaction product in the secondary hydrogenation reactor is 5.0h -1 (3) The gas velocity of replenishing hydrogen in the secondary reactor is 0.20m / s.

Embodiment 3

[0080] The method of Example 1 is used to hydrogenate 1,4-butynediol aqueous solution to prepare 1,4-butanediol and co-produce 1,4-butenediol, the only difference is: fluidized bed reactor 1 Catalyst is Ni 91.0 Al 9.0 , the catalyst in the fixed bed reactor 2 is Pd / Al with a Pd loading of 1.0% by weight 2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com