Preparation method of methyl 2, 3-diaminobenzoate

A technology of methyl diaminobenzoate and nitrobenzoic acid, which is applied in the field of preparation of methyl 2,3-diaminobenzoate, can solve problems such as low purity, high raw material prices, and risk of explosion, and achieve a synthetic route Short, simple preparation method, easy to handle and purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]

[0037] (1) Synthesis of 3-amino-2-nitrobenzoic acid (2):

[0038] Add 150mL of purified water and 0.83g (0.006mol) of copper chloride to a 250mL four-necked bottle, then add 25g (0.124mol) of 3-chloro-2-nitrobenzoic acid, stir, and feed ammonia gas (flow rate 0.1ml Every minute), be warming up to 120 ℃, insulation reaction 6 hours, treat that reaction finishes, close ammonia gas, cool down, crystallize, filter, dry to obtain 21.3g of 3-amino-2-nitrobenzoic acid, purity is 97.4%, yield The rate is 92.8%.

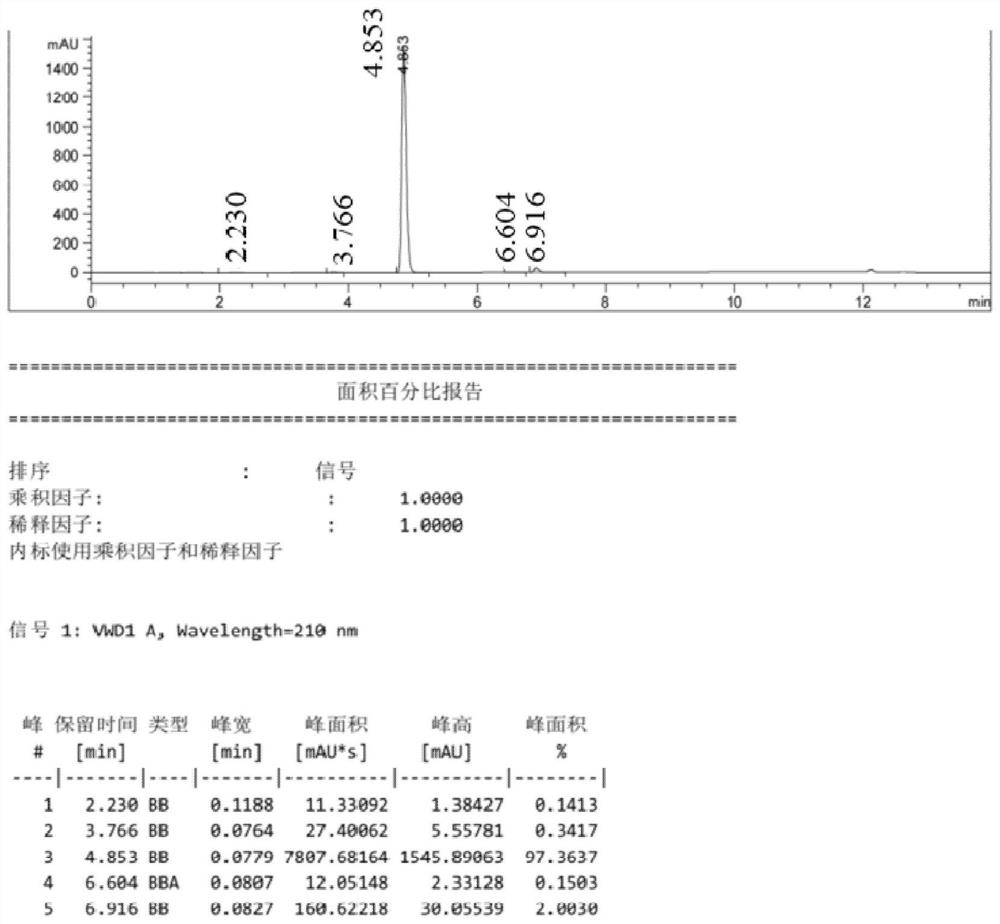

[0039] (2) Synthesis of 3-amino-2-nitrobenzoic acid methyl ester (3):

[0040] Add 50.0 g (0.273 mol) of 3-amino-2-nitrobenzoic acid and 800 mL of methanol into a 1000 mL four-neck flask, resulting in a yellow turbid system. Control the temperature at 20-30°C, add 40.1g (0.410mol) of concentrated sulfuric acid, raise the temperature to 70-75°C, stir for 4 hours, then cool down to below 5°C. Control the temperature T≤5°C, add sodium hydroxide to adjust the pH of...

Embodiment 2

[0044]

[0045] (1) Synthesis of 3-amino-2-nitrobenzoic acid (2):

[0046] Add 150mL of purified water and 16.7g (0.124mol) of copper chloride to a 250mL four-necked bottle, then add 25g (0.124mol) of 3-chloro-2-nitrobenzoic acid, stir, and feed ammonia gas (flow rate 0.1ml Every minute), be warming up to 120 ℃, insulation reaction 6 hours, treat that reaction finishes, close ammonia gas, cool down, crystallize, filter, dry to obtain 21.3g of 3-amino-2-nitrobenzoic acid, purity is 98.2%, yield The rate is 92.6%.

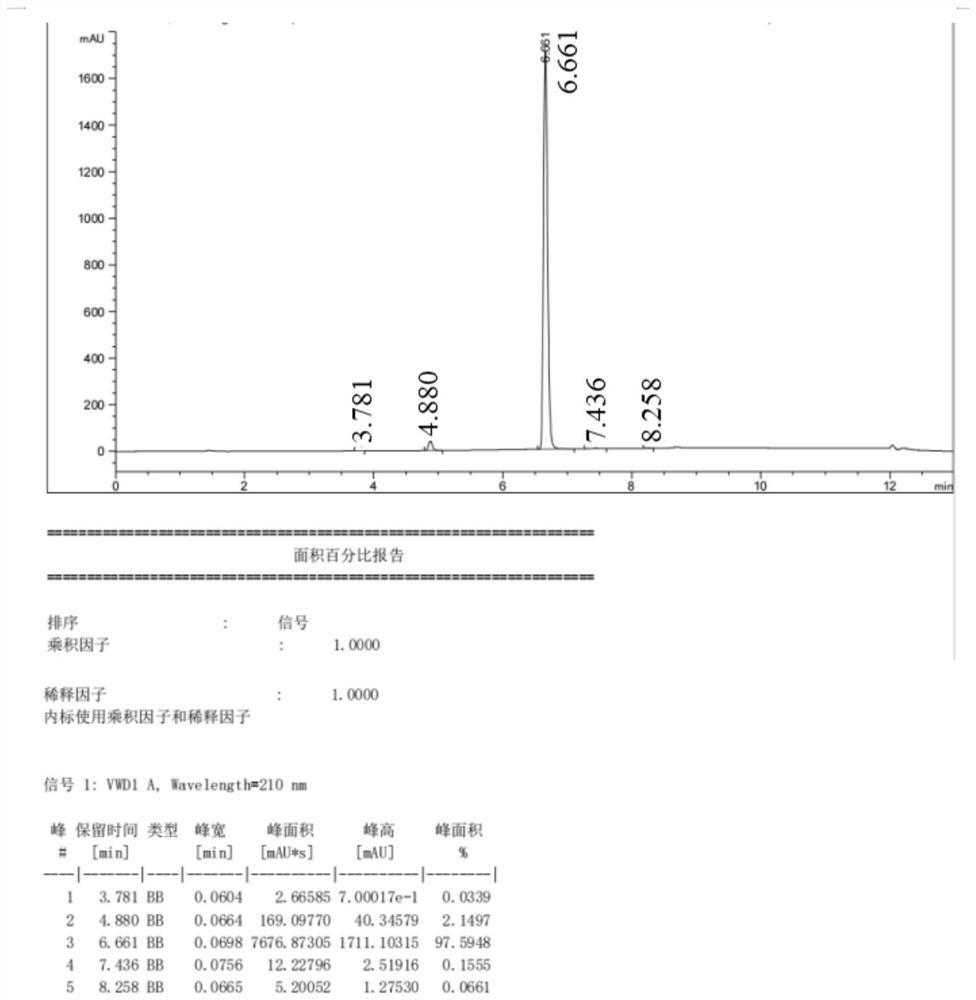

[0047] (2) Synthesis of 3-amino-2-nitrobenzoic acid methyl ester (3):

[0048]Add 50.0 g (0.273 mol) of 3-amino-2-nitrobenzoic acid and 800 mL of methanol into a 1000 mL four-neck flask, resulting in a yellow turbid system. Control the temperature at 20-30°C, add 40.3g (0.411mol) of concentrated sulfuric acid, raise the temperature to 70-75°C, stir for 4 hours, then cool down to below 5°C. Control the temperature T≤5°C, add sodium hydroxide to adjust the pH of ...

Embodiment 3

[0052]

[0053] (1) Synthesis of 3-amino-2-nitrobenzoic acid (2):

[0054] Add 150mL of purified water and 16.7g (0.124mol) of copper chloride to a 250mL four-necked bottle, then add 25g (0.124mol) of 3-chloro-2-nitrobenzoic acid, stir, and feed ammonia gas (flow rate 0.1ml Every minute), be warming up to 120 ℃, insulation reaction 6 hours, treat that reaction finishes, close ammonia gas, cool down, crystallize, filter, dry to obtain 21.3g of 3-amino-2-nitrobenzoic acid, purity is 97.2%, yield The rate is 91.6%.

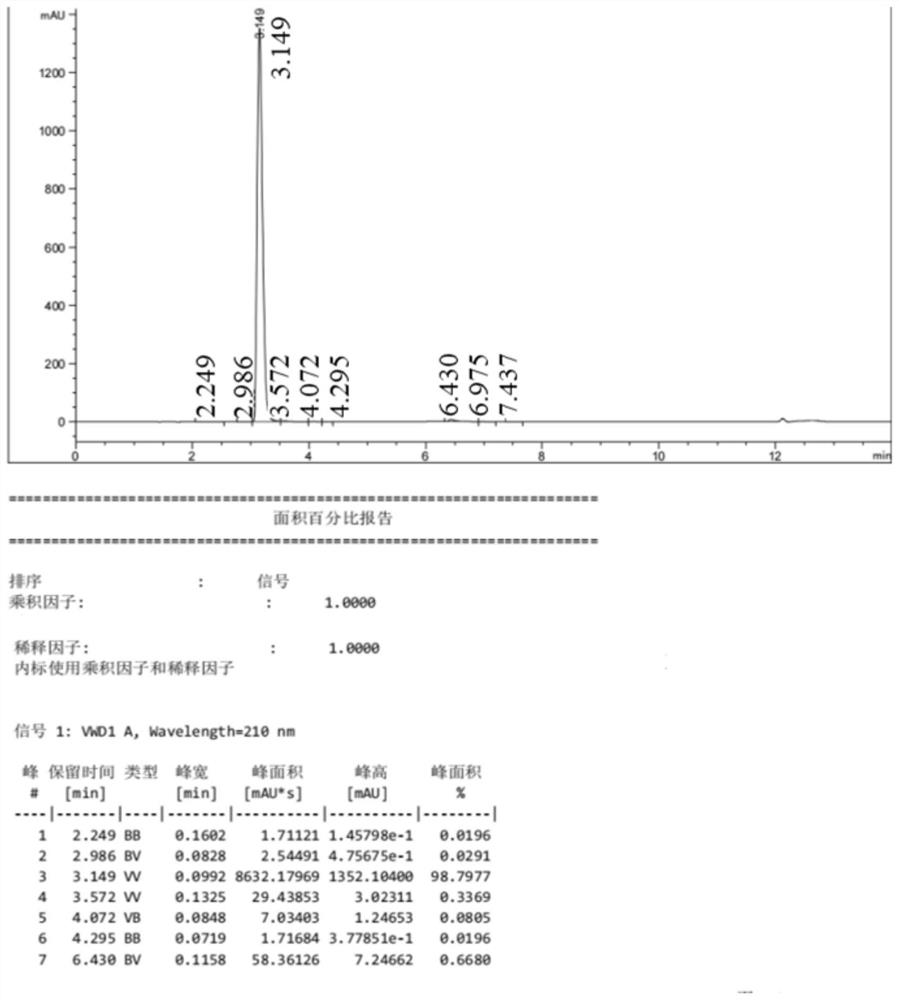

[0055] (2) Synthesis of 3-amino-2-nitrobenzoic acid methyl ester (3):

[0056] Add 50.0 g (0.273 mol) of 3-amino-2-nitrobenzoic acid and 800 mL of methanol into a 1000 mL four-neck flask, resulting in a yellow turbid system. Control the temperature at 20-30°C, add 53.5g (0.546mol) of concentrated sulfuric acid, raise the temperature to 70-75°C, stir for 4 hours, then cool down to below 5°C. Control the temperature T≤5°C, add sodium hydroxide to adjust the pH of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com