Modified starch and preparation method thereof, microbubble drilling fluid and application

A drilling fluid and starch technology, applied in chemical instruments and methods, drilling compositions, geothermal power generation, etc., can solve the problems of insufficient temperature resistance, unsatisfactory salt and calcium resistance effects, and high use costs, and achieve excellent Effects of water solubility, strong shear thinning and rock-carrying ability, and excellent high temperature foam stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

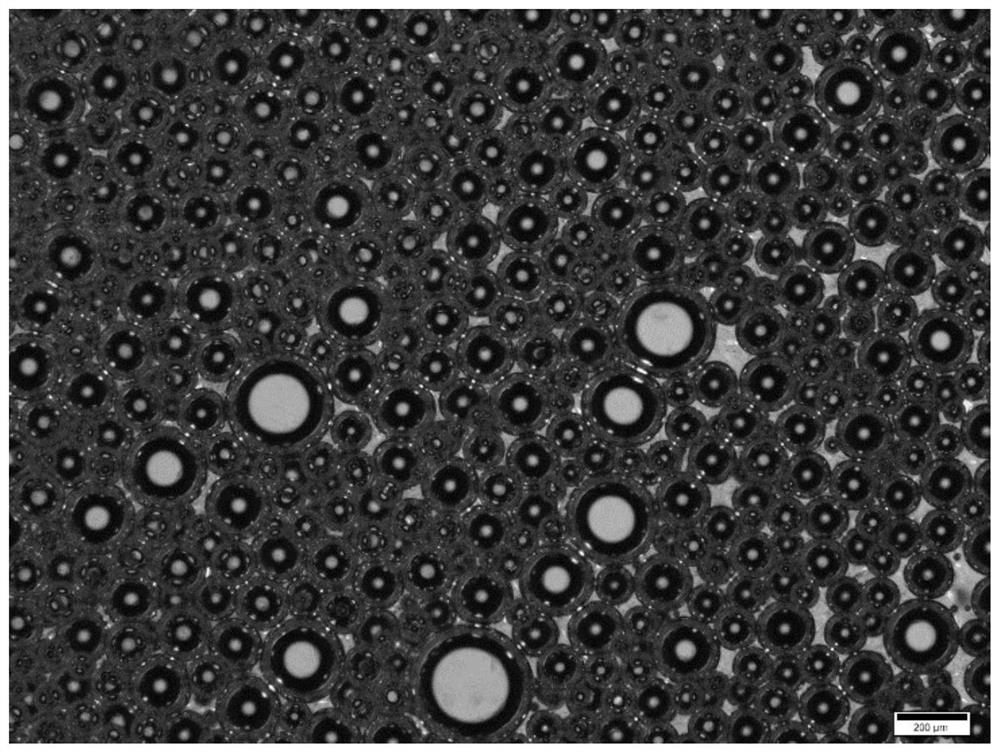

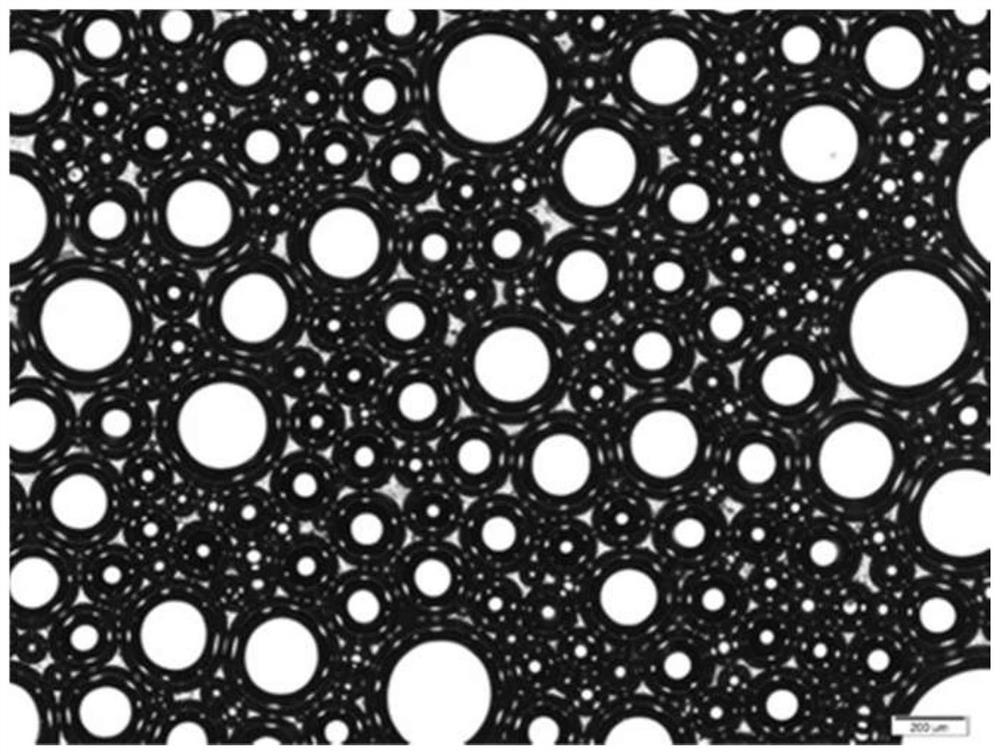

Image

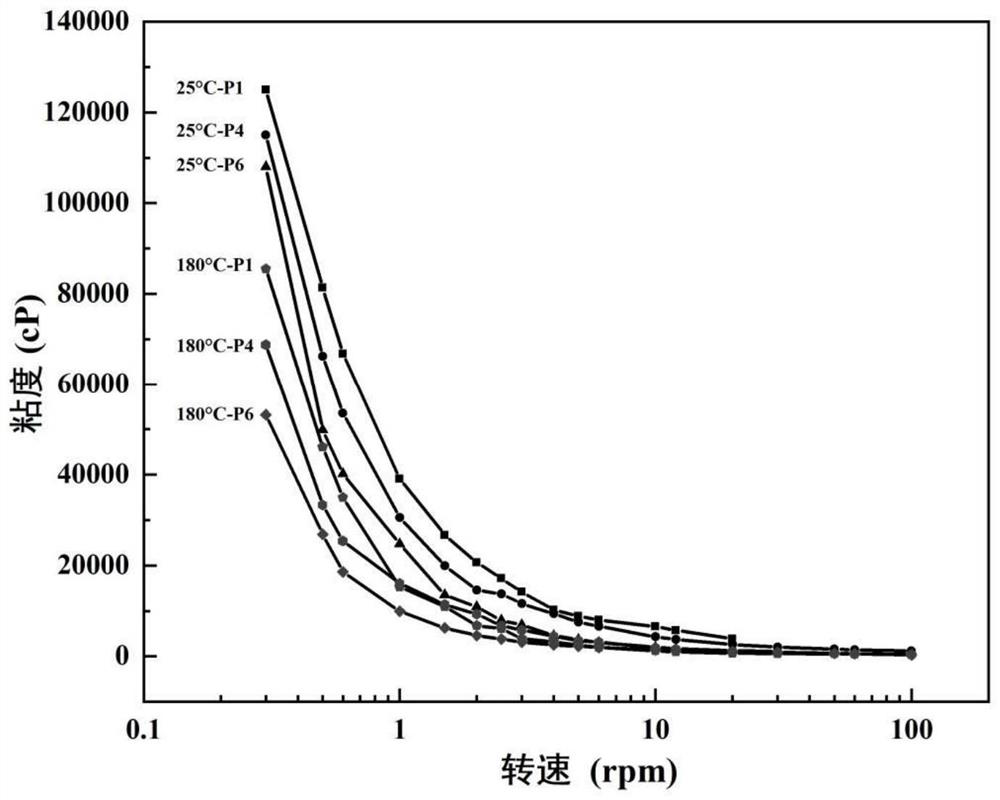

Examples

preparation example Construction

[0027] The first aspect of the present invention provides a kind of preparation method of modified starch, the method comprises:

[0028] (1) Starch and water are made into a gelatinized starch solution, and the first monomer, the second monomer, and the third monomer are made into a monomer solution with water, and then the gelatinized starch solution and the monomer solution are Mix with a hydrophilic emulsifier to obtain an aqueous phase solution;

[0029] (2) mixing the lipophilic emulsifier with liquid paraffin and emulsifying to obtain an oil phase solution; adding the water phase solution to the oil phase solution to obtain a water-in-oil type inverse emulsion system;

[0030] (3) In the presence of an initiator, the water-in-oil type inverse emulsion system is subjected to a graft copolymerization reaction to obtain a reaction product system;

[0031] (4) The reaction product system is subjected to demulsification, washing and subsequent treatment to obtain modified s...

preparation example 1

[0067] (1-A) Dissolve the soluble starch in deionized water, and use a magnetic heating stirrer to heat and stir at 90° C. for 0.75 h to perform pregelatinization treatment to obtain a transparent gelatinized starch solution (concentration: 30% by weight) ;

[0068] (1-B) Weigh the grafted monomers NVP, AMPS, AM according to the monomer molar ratio 1:2:4 and dissolve them in deionized water to obtain a monomer solution (the total concentration of each monomer is 60% by weight), and then use NaOH aqueous solution adjusts the pH value of the monomer solution to 8;

[0069] (1-C) Mix the above-mentioned gelatinized starch solution with the monomer solution, and then add Triton X-100 to continue mixing to obtain an aqueous phase solution;

[0070] In the above steps, the weight ratio of soluble starch: (NVP+AMPS+AM) is 50:100; the weight ratio of Triton X-100: (NVP+AMPS+AM) is 3:100;

[0071] (2) Dissolve Span 80 in liquid paraffin, use a high-speed shear emulsifier to stir, mix...

preparation example 2

[0078] (1-A) Dissolve the soluble starch in deionized water, and use a magnetic heating stirrer to heat and stir at 85° C. for 0.5 h to perform pregelatinization treatment to obtain a transparent gelatinized starch solution (concentration: 30% by weight) ;

[0079] (1-B) Weigh the grafted monomers NVP, AMPS, AM according to the monomer molar ratio 1:4:6 and dissolve them in deionized water to obtain a monomer solution (the total concentration of each monomer is 60% by weight), and then use NaOH aqueous solution adjusts the pH value of the monomer solution to 7.5;

[0080] (1-C) Mix the above-mentioned gelatinized starch solution with the monomer solution, and then add Triton X-100 to continue mixing to obtain an aqueous phase solution;

[0081] In the above steps, the weight ratio of soluble starch: (NVP+AMPS+AM) is 50:100; the weight ratio of Triton X-100: (NVP+AMPS+AM) is 16:100;

[0082] (2) Dissolve Span 80 in liquid paraffin, use a high-speed shear emulsifier to stir, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com