Coating thickening water-retaining agent and preparation method thereof

A thickening water-retaining agent and coating technology, applied in paper coating, coating, fiber raw material treatment, etc., can solve problems such as poor water retention, inability to increase vehicle speed, and residual monomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

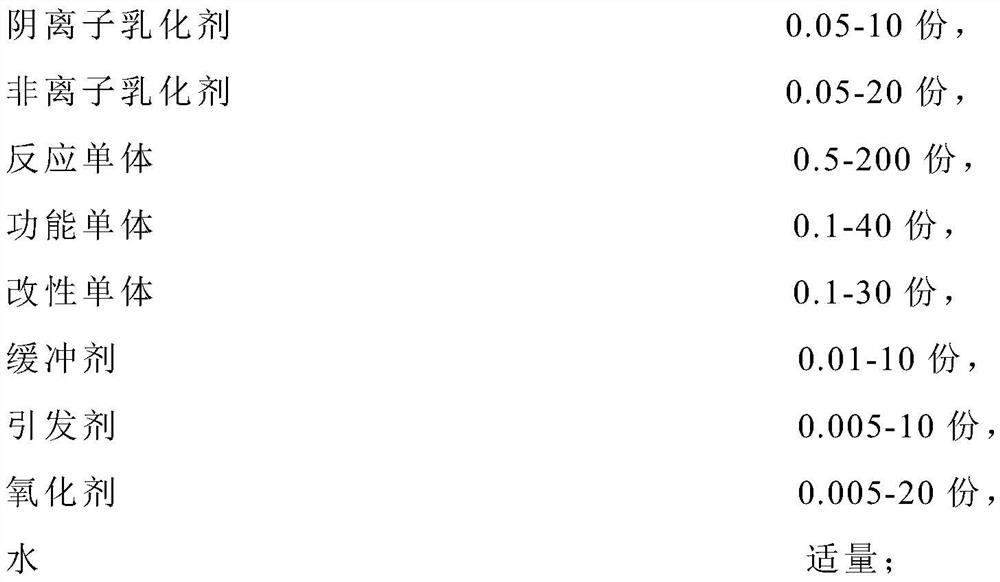

Method used

Image

Examples

Embodiment 1

[0072] A paint thickening and water-retaining agent, prepared through the following steps:

[0073] 1. Add emulsifier K (anionic emulsifier sodium dodecylsulfonate) 0.2g, emulsifier AEO-151g, add water 50g, stir and mix well, then add sodium bicarbonate 0.1g, mix Evenly, add 2g of BEM, 1.5g of SEM, mix well, add 0.5g of N,N-methylenebisacrylamide, mix well, then add 24g of methacrylic acid, 5g of methyl methacrylate, 29g of ethyl acrylate, 3g of hydroxyethyl methacrylate was stirred and emulsified to obtain a pre-emulsion;

[0074] 2. Weigh 0.02g of initiator (sodium persulfate), add 5g of water, and stir to completely dissolve;

[0075] 3. Add 60g of water to the reaction kettle, then add 0.5g of emulsifier DBR-Z, start stirring, and raise the temperature to 82°C;

[0076] 4. Add the initiator (sodium persulfate) aqueous solution obtained in step 2 into the reactor, stir for 2min, then add 3g of pre-emulsion, stir and react, the stirring speed is controlled at 180-200r / min,...

Embodiment 2

[0083] A paint thickening and water-retaining agent, prepared through the following steps:

[0084] 1. Add 0.3g of emulsifier K (anionic emulsifier sodium dodecylbenzenesulfonate), 1.1g of emulsifier AEO-15, 50g of water, stir and mix well, and then add 0.08 sodium bicarbonate g, mix well, then add BEM 3g, SEM 2g, mix well, add N,N-methylenebisacrylamide 0.3g, mix well, then add methacrylic acid 28g, butyl acrylate 6.7g, ethyl acrylate 20g, Hydroxyethyl methacrylate 5g is stirred and emulsified to obtain a pre-emulsion;

[0085] 2. Weigh 0.02g of initiator (ammonium persulfate), add 5g of water, and stir to completely dissolve;

[0086] 3. Add 60g of water into the reaction kettle, then add 0.45g of emulsifier DBR-Z, start stirring, and raise the temperature to 85°C;

[0087] 4. Add the initiator (ammonium persulfate) obtained in step 2 into the reactor, stir for 2min, then add 5g of pre-emulsion, stir and react, the stirring speed is controlled at 180-200r / min, and the reac...

Embodiment 3

[0094] A paint thickening and water-retaining agent, prepared through the following steps:

[0095] 1. Add 0.4g of emulsifier K (anionic emulsifier sodium dodecylbenzenesulfonate), 1.05g of emulsifier AEO-15, 50g of water, stir and mix well, and then add 0.05g of sodium bicarbonate g, mix well, then add BEM1g, SEM3g, mix well, add N,N-methylenebisacrylamide 0.5g, mix well, then add methacrylic acid 25g, methyl methacrylate 5g, ethyl acrylate 27g, 3.5g of hydroxyethyl acrylate was stirred and emulsified to obtain a pre-emulsion;

[0096] 2. Weigh 0.02g of initiator (ammonium persulfate), add 5g of water, and stir to completely dissolve;

[0097] 3. Add 60g of water to the reaction kettle, then add 0.4g of emulsifier DBR-Z, start stirring, and raise the temperature to 85°C;

[0098] 4. Add the initiator (ammonium persulfate) obtained in step 2 into the reactor, stir for 2min, then add 5g of pre-emulsion, stir and react, the stirring speed is controlled at 180-200r / min, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com