Organosilicon polyether copolymer as well as preparation method and application thereof

A technology of polyether copolymer and silicone, which is applied in the field of silicone polyether copolymer and its preparation, can solve the problems of polyurethane foam performance such as poor pore size, thermal conductivity and closed cell content, complex reaction process, and poor adjustability , to achieve the effect of large openness, simple synthesis process and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

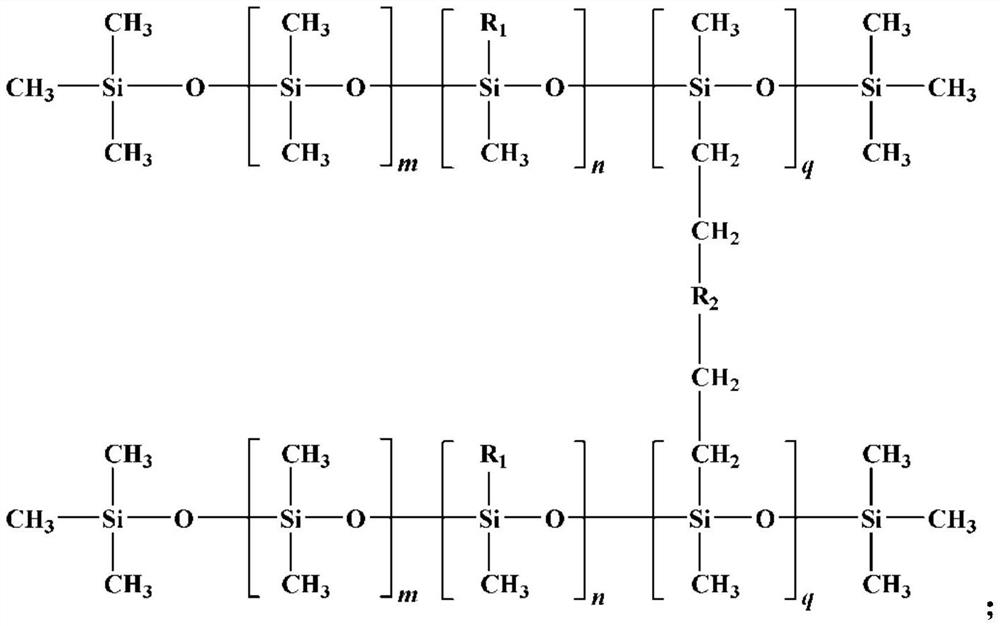

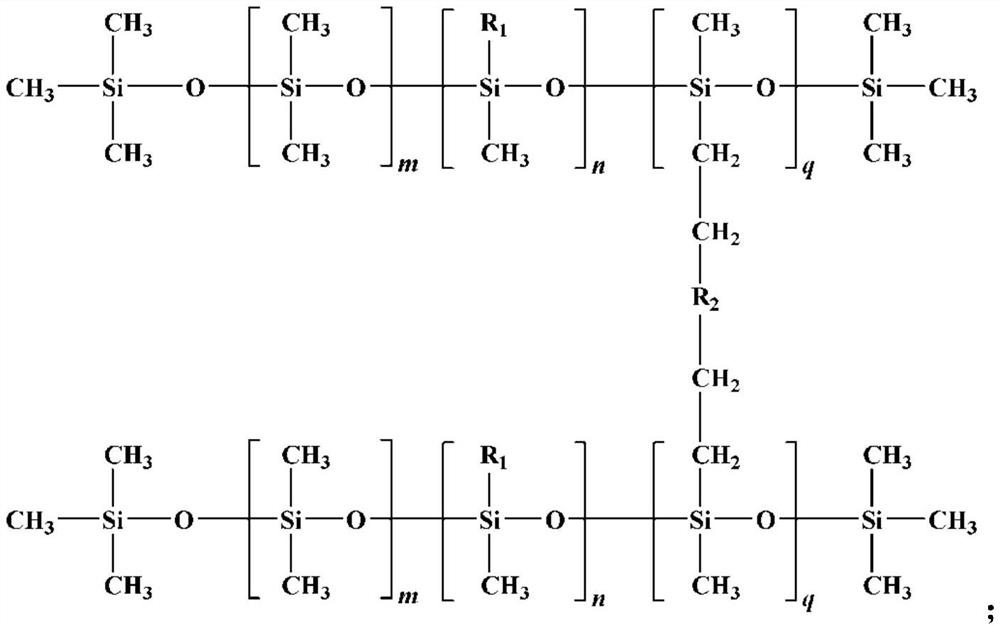

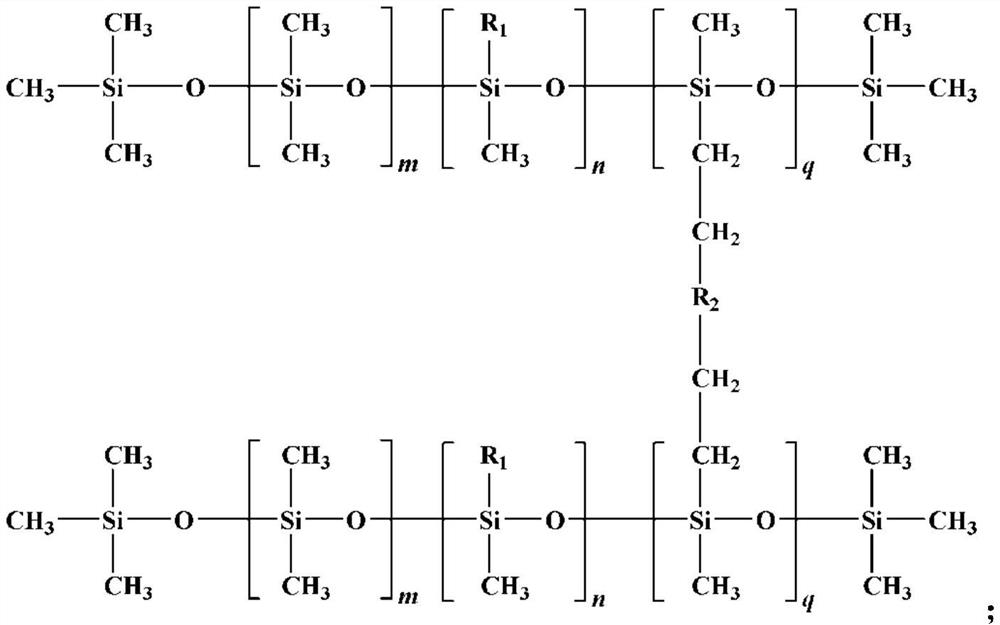

Image

Examples

preparation example Construction

[0065] Correspondingly, the present application also provides a preparation method of the above-mentioned silicone polyether copolymer, for example, may include the following steps: alkanes, vinyl-terminated polysiloxanes, and allyl polyethers, followed by solvent removal.

[0066] In a preferred embodiment, the polydimethyl-methylhydrogensiloxane is first reacted with a vinyl-terminated polysiloxane and subsequently reacted with an allyl polyether. Specifically, vinyl-terminated polysiloxane may be added dropwise into polydimethyl-methylhydrogensiloxane.

[0067] In the present application, the reaction between polydimethyl-methylhydrogensiloxane and vinyl-terminated polysiloxane can be carried out at 80-130°C (such as 80°C, 85°C, ℃, 90℃, 95℃, 100℃, 105℃, 110℃, 115℃, 120℃, 125℃ or 130℃, etc.) for 0.5-1h (such as 0.5h, 0.6h, 0.7h, 0.8h, 0.9h or 1h, etc.).

[0068] In addition, during the reaction process of polydimethyl-methylhydrogensiloxane and vinyl-terminated polysiloxa...

Embodiment 1

[0083] This embodiment provides a kind of silicone polyether copolymer, and its preparation method is as follows:

[0084] (1) Add 169.34g of octamethylcyclotetrasiloxane, 18.31g of tetramethylcyclotetrasiloxane and 12.36g of hexamethyldisiloxane into the reactor, under the action of 10.00g of acid clay, at 80°C React for 4h to obtain polydimethyl-methylhydrogensiloxane.

[0085] (2) Add 70.48g of octamethylcyclotetrasiloxane and 29.52g of tetramethyldivinyldisiloxane into the reactor, and react at 80°C for 4h under the action of 5.00g of acid clay to obtain vinyl-terminated polystyrene Dimethicone.

[0086] (3) Add 127.35g of polydimethyl-methylhydrogensiloxane, 30g of isopropanol, 6ppm of chloroplatinic acid catalyst and 150ppm of triethanolamine cocatalyst into the reactor, heat up to 80-90°C under normal pressure, and Add 6.43g of vinyl-terminated polydimethylsiloxane dropwise within 0.5h, and keep warm for 0.5h after the dropwise addition; then add 166.23g of allyl poly...

Embodiment 2

[0092] This embodiment provides a kind of silicone polyether copolymer, and its preparation method is as follows:

[0093] (1) Add 171.81g of octamethylcyclotetrasiloxane, 19.44g of tetramethylcyclotetrasiloxane and 8.75g of hexamethyldisiloxane into the reactor, and react at 30°C under the action of 4.00g of sulfuric acid 8h, polydimethyl-methylhydrogensiloxane was obtained.

[0094] (2) Add 81.40 g of octamethylcyclotetrasiloxane and 18.60 g of tetramethyldivinyldisiloxane into the reactor, react with 2.00 g of clay sulfate at 30°C for 8 hours to obtain vinyl-terminated polystyrene Dimethicone.

[0095] (3) Add 93.91g of polydimethyl-methylhydrogensiloxane, 24g of toluene, 7ppm of chloroplatinic acid catalyst and 200ppm of triethylamine cocatalyst into the reactor, and heat up to 110-120°C under normal pressure. Add 4.18g of vinyl-terminated polydimethylsiloxane dropwise within h, and keep warm for 0.5h after the dropwise addition; then add 201.90g of allyl polyether, fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com