A kind of ultra-light foam concrete and preparation method thereof

A technology of foam concrete and concrete, which is applied in the field of building energy-saving and thermal insulation materials, can solve the problems of sewage pollution, dust pollution, etc., and achieve the effects of convenient construction, improved strength in the later stage, improved slurry consistency and foam stabilization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The admixture of the material component and its compounding ratio adopted in the present embodiment is as follows:

[0058] 52.5 grade ordinary Portland cement: 120kg

[0059] 42.5 grade rapid hardening sulfoaluminate cement: 20kg

[0060] Concrete mixing station sludge: 40kg

[0061] Ether polycarboxylate superplasticizer with a solid content of 20%: 0.5kg

[0062] Polyvinyl acetate-ethylene copolymer latex powder (VAE): 2kg

[0063] Hydroxypropyl methylcellulose ether (HPMC) with a viscosity of 100,000 Pa·s: 0.1kg

[0064] Polypropylene monofilament staple fiber: 1kg

[0065] Calcium stearate: 0.2kg

[0066] Sintered shale brick powder: 1.0kg

[0067] Hydrogen peroxide with a mass concentration of 30.0%: 6kg

[0068] Tap water: 80kg

[0069] Wherein, the sintered shale brick powder is obtained by crushing sintered shale bricks and passing through a 75-micron sieve, and the concrete mixing station sludge is obtained by drying the flocculent sediment in the sedi...

Embodiment 2

[0076] The admixture of the material component and its compounding ratio adopted in the present embodiment is as follows:

[0077] 52.5 grade ordinary Portland cement: 100kg

[0078] 42.5 grade rapid hardening sulfoaluminate cement: 30kg

[0079] Concrete mixing station sludge: 60kg

[0080] Ether polycarboxylate superplasticizer with a solid content of 20%: 1.0kg

[0081] Polyvinyl acetate-ethylene copolymer latex powder (VAE): 2.5kg

[0082] Hydroxypropyl methyl cellulose ether (HPMC) with a viscosity of 100,000 Pa·s: 0.2kg

[0083] Polypropylene monofilament staple fiber: 1.5kg

[0084] Calcium stearate: 0.3kg

[0085] Sintered shale brick powder: 1.5kg

[0086] Hydrogen peroxide with a mass concentration of 30.0%: 6.5kg

[0087] Tap water: 60kg

[0088] Wherein, the sintered shale brick powder is obtained by crushing sintered shale bricks and passing through a 75-micron sieve, and the concrete mixing station sludge is obtained by drying the flocculent sediment in t...

Embodiment 3

[0091] The admixture of the material component and its compounding ratio adopted in the present embodiment is as follows:

[0092] 52.5 grade ordinary Portland cement: 100kg

[0093] 42.5 grade rapid hardening sulfoaluminate cement: 40kg

[0094] Concrete mixing station sludge: 80kg

[0095] Ether polycarboxylate superplasticizer with a solid content of 20%: 1.0kg

[0096] Polyvinyl acetate-ethylene copolymer latex powder (VAE): 3.0kg

[0097] Hydroxypropyl methyl cellulose ether (HPMC) with a viscosity of 100,000 Pa·s: 0.2kg

[0098] Polypropylene monofilament staple fiber: 1.5kg

[0099] Calcium stearate: 0.3kg

[0100] Sintered shale brick powder: 1.5kg

[0101] Hydrogen peroxide with a mass concentration of 30.0%: 7kg

[0102] Tap water: 60kg

[0103] Wherein, the sintered shale brick powder is obtained by crushing sintered shale bricks and passing through a 75-micron sieve, and the concrete mixing station sludge is obtained by drying the flocculent sediment in the...

PUM

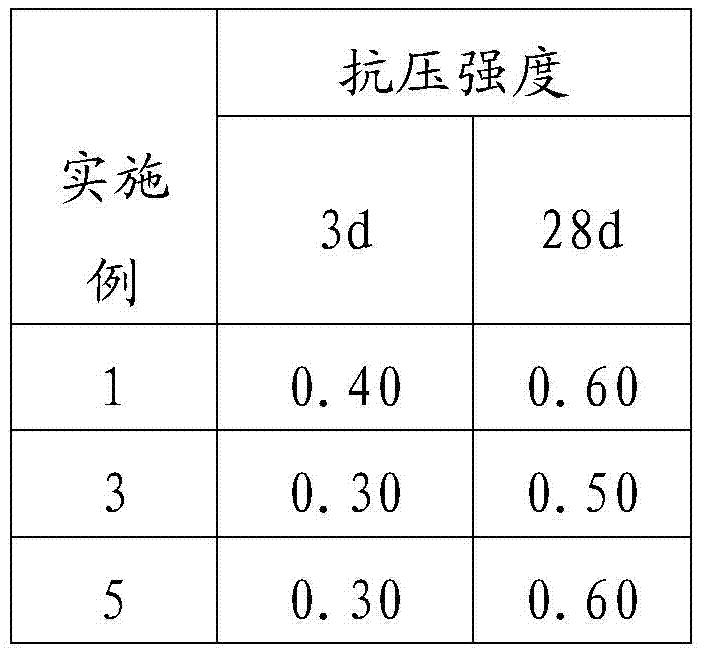

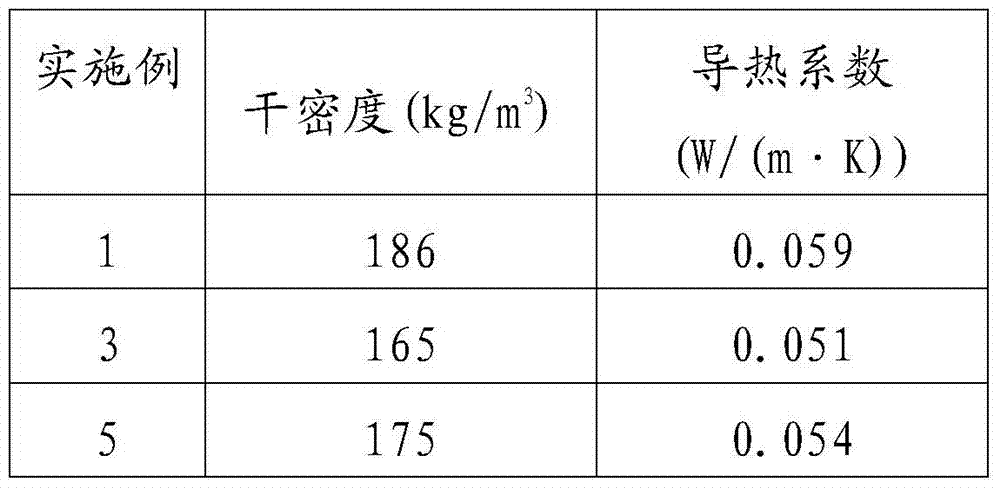

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com