Polyurethane flame-retardant anti-static super-wear-resistant finish paint and preparation method thereof

An anti-static and super-wear-resistant technology, used in polyurea/polyurethane coatings, fire-retardant coatings, conductive coatings, etc., can solve the problems of difficulty in dispersion and the decline in the conductivity of conductive fillers, and achieve good flame retardant performance and excellent anti-static performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A polyurethane flame-retardant anti-static super wear-resistant finish, including A component, B component and C component, the specific preparation steps are as follows:

[0050] Preparation of component B: Put polyurethane color paste and anti-settling agent into the stirring tank, stir at 800rpm / min for 10 minutes, add dispersant, leveling agent and catalyst while stirring, continue stirring for 5 minutes, then add conductive agent and resisting agent Combustion agent, increase the speed to 1000rpm / min and disperse for 20min, then reduce the speed to 600rpm / min, add ester diluent, stir for 5min before packing;

[0051] Component A adopts the isocyanate curing agent in finished product packaging, and its specific model is Covestro 3300;

[0052] Component C is white corundum with finished product packaging, and the particle size of white corundum is composed of 180 mesh white corundum, 220 mesh white corundum and 240 mesh white corundum according to the weight ratio o...

Embodiment 2-5

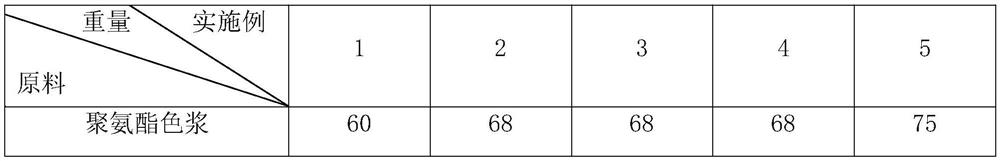

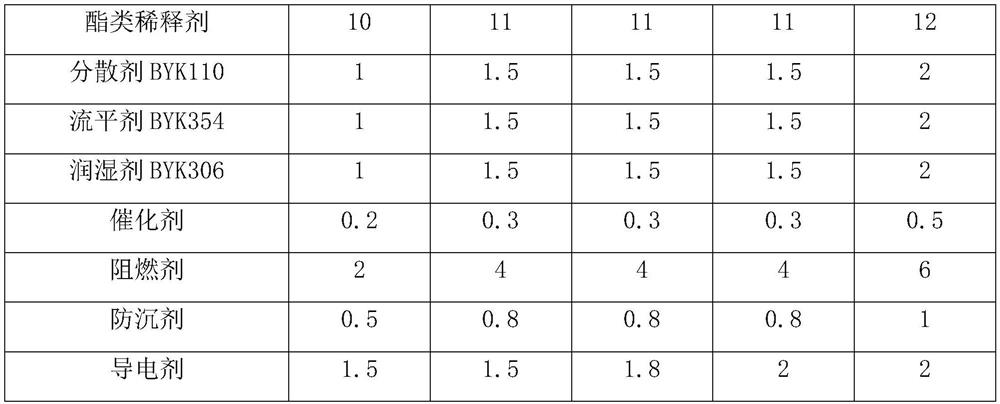

[0057] A polyurethane flame-retardant anti-static super wear-resistant finish, the difference from Example 1 is that the raw materials in component B and their corresponding weights are shown in Table 1 below.

[0058] Each raw material and its weight (kg) in the B component in the embodiment 1-5 of table 1

[0059]

[0060]

Embodiment 6

[0062] A polyurethane flame-retardant anti-static super wear-resistant finish, the difference from Example 1 is that the C component uses white corundum in finished product packaging, and the particle size of the white corundum is 180 mesh white corundum, 220 mesh white corundum and 240 mesh white corundum according to Composition by weight ratio 1:2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com