Imitation handmade hemp scraping type hemp fiber whole-bone stripping machine and use method thereof

A technology imitating handwork and fiber, applied in the direction of fiber mechanical separation, fiber treatment, mechanical treatment, etc., can solve the problems of inability to guarantee the integrity of hemp fiber, inclined dislocation of hemp fiber crack, and hemp fiber breakage, so that the operation steps are not cumbersome, It is convenient to peel off the hemp and ensure the integrity of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

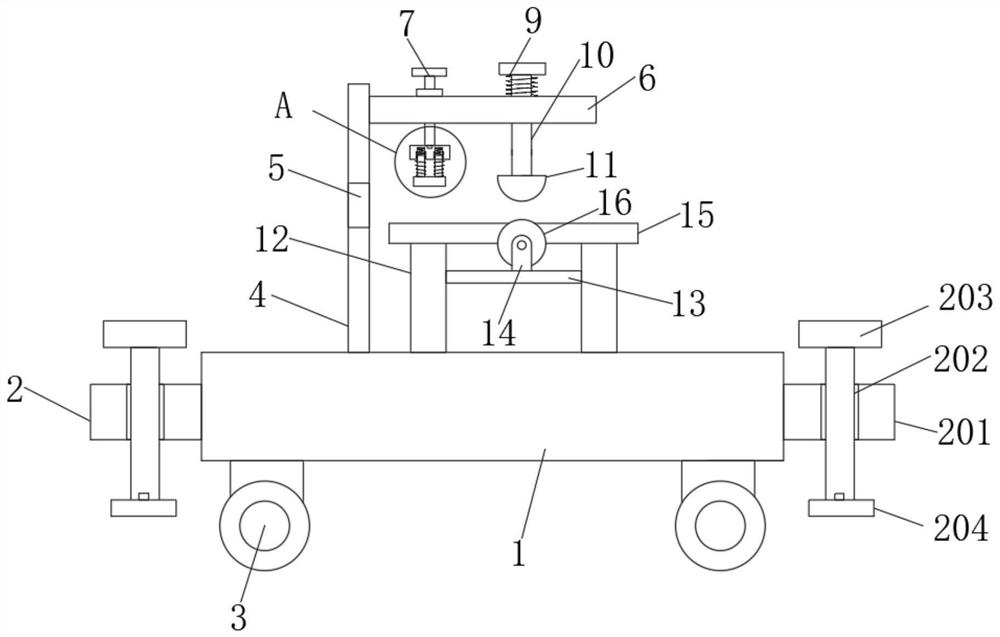

[0030] see Figure 1~3 , a hand-scraped hemp-type hemp fiber bone-setting and peeling machine, including

[0031] The base 1 is fixedly connected with support mechanisms 2 at both ends, and a support column 4 is fixedly connected with one side of its upper surface. A support leg 12 is fixedly connected to the right side of the column 4, and an operating table 15 is fixedly connected to the upper end of the support leg 12;

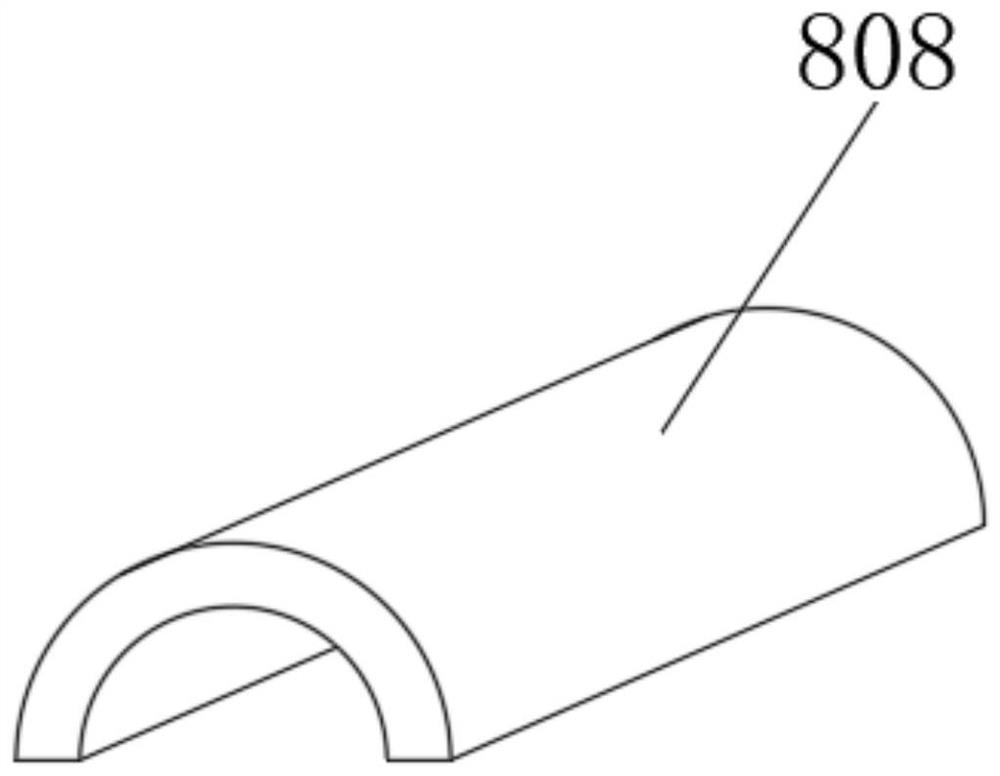

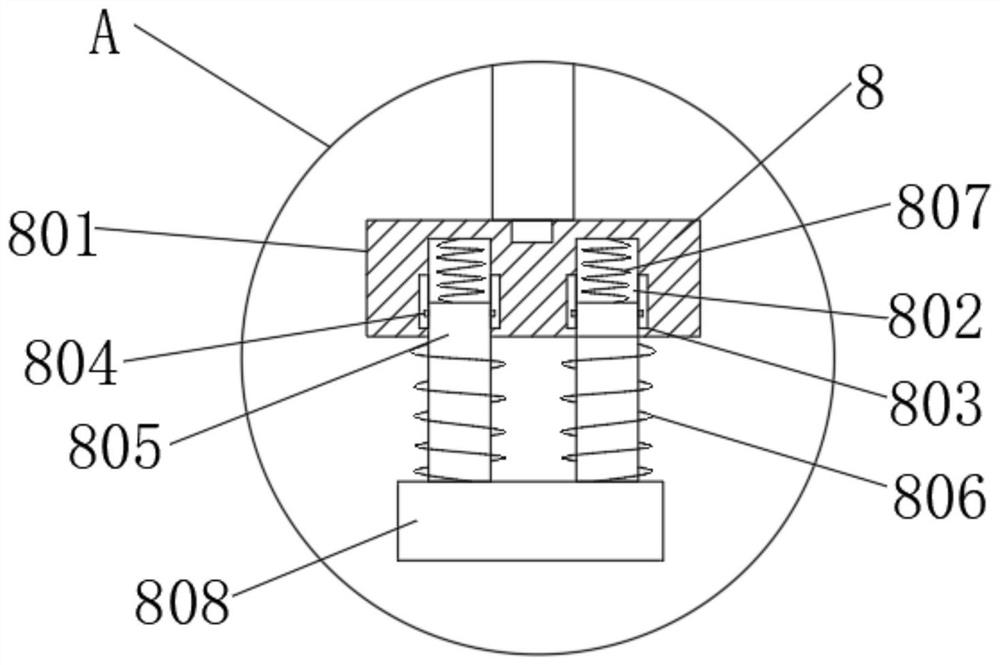

[0032] Limiting mechanism 8, it is installed on the lower end of described adjusting screw rod one 7, and described adjusting screw rod one 7 is threaded in one side inside of described horizontal support rod 6, by setting limiting mechanism 8, when peeling, Limit the position of the hemp rod to avoid its swing and ensure the smooth peeling of hemp;

[0033] Cutting mechanism, its part is arranged on described horizontal support rod 6 lower sides, and its other part is arranged on the inboard of described operating table 15, by setting cutting mechanism, ...

Embodiment 2

[0038] see Figure 1~3 , a hand-scraped hemp-type hemp fiber bone-setting and peeling machine, including

[0039] The base 1 is fixedly connected with support mechanisms 2 at both ends, and a support column 4 is fixedly connected with one side of its upper surface. A support leg 12 is fixedly connected to the right side of the column 4, and an operating table 15 is fixedly connected to the upper end of the support leg 12;

[0040] Limiting mechanism 8, it is installed on the lower end of described adjusting screw rod one 7, and described adjusting screw rod one 7 is threaded in one side inside of described horizontal support rod 6, by setting limiting mechanism 8, when peeling, Limit the position of the hemp rod to avoid its swing and ensure the smooth peeling of hemp.

[0041]In the embodiment of the present invention, the inside of the support column 4 is provided with a perforation 5, and the perforation 5 is larger than the diameter of the hemp rod, which is convenient f...

Embodiment 3

[0044] A hand-scraped hemp-type hemp fiber bone-setting and peeling machine, the use method of which is as follows:

[0045] a. Move the peeling machine to a proper position through the universal wheel 3, and then turn the adjusting screw 2 203, so that the adjusting screw 2 203 drives the pressing plate 204 to move downward until the universal wheel 3 is off the ground, and then stop turning Adjusting screw two 203;

[0046] B, then adjust the height of the limit mechanism 8 according to the approximate thickness of the hemp rod, and rotate the adjustment screw rod one 7, so that the adjustment screw rod one 7 drives the limit mechanism 8 to descend, thereby adjusting the height of the limit mechanism 8;

[0047] c. Then pass the hemp rod through the perforation 5 with the left hand so that it is placed on the surface of the operating table 15, and then apply force to the pressing rod 9 with the left hand to make it drive the cutting knife 11 close to the hob 16. At the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com