Vehicle induction motor driving torque high-performance time-sharing control system and control method

An induction motor, time-sharing control technology, applied in the control system, vector control system, motor generator control, etc., can solve the problems that the closed-loop system cannot guarantee the consistent convergence characteristics, direct torque control large torque, torque control time delay, etc. Achieve the effect of ensuring overall consistent convergence characteristics, reducing hardware costs, and avoiding time delays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The present invention will be further described below in conjunction with the accompanying drawings.

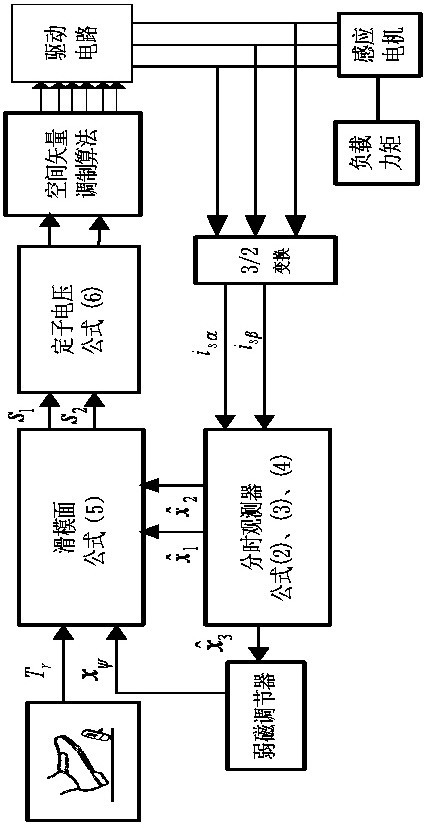

[0094] refer to figure 1 , the high-performance time-sharing control system for vehicle induction motor drive torque of the present invention is used in electric vehicles, the electric vehicle has a vehicle-mounted ECU, an induction motor and a drive circuit for driving the induction motor, the vehicle-mounted ECU has a 3 / 2 converter, and the electric vehicle A pedal displacement sensor is installed on the pedal, and the pedal displacement sensor is connected with the vehicle ECU through the vehicle circuit;

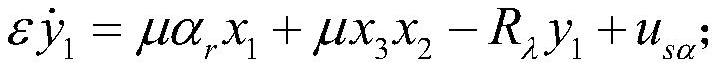

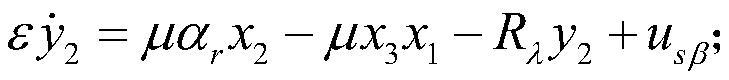

[0095] The vehicle-mounted ECU stores the induction motor state equation (that is, formula 1), the torque control sliding mode surface formula (that is, formula 5), the stator voltage formula (that is, formula 6), space vector modulation algorithm, sliding mode time-sharing observer and field weakening Regulator; Equation 1 is the model of the induction motor an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com