High-performance power supply control board

A power control and high-performance technology, which is applied in the fields of printed circuit manufacturing, electrical components, printed circuits, etc., can solve the problems of difficult splicing of power control boards, uneven copper plating thickness, and low plating efficiency, so as to reduce the risk of seepage, The effect of improving processing efficiency and uniformity, and improving the uniformity of copper plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

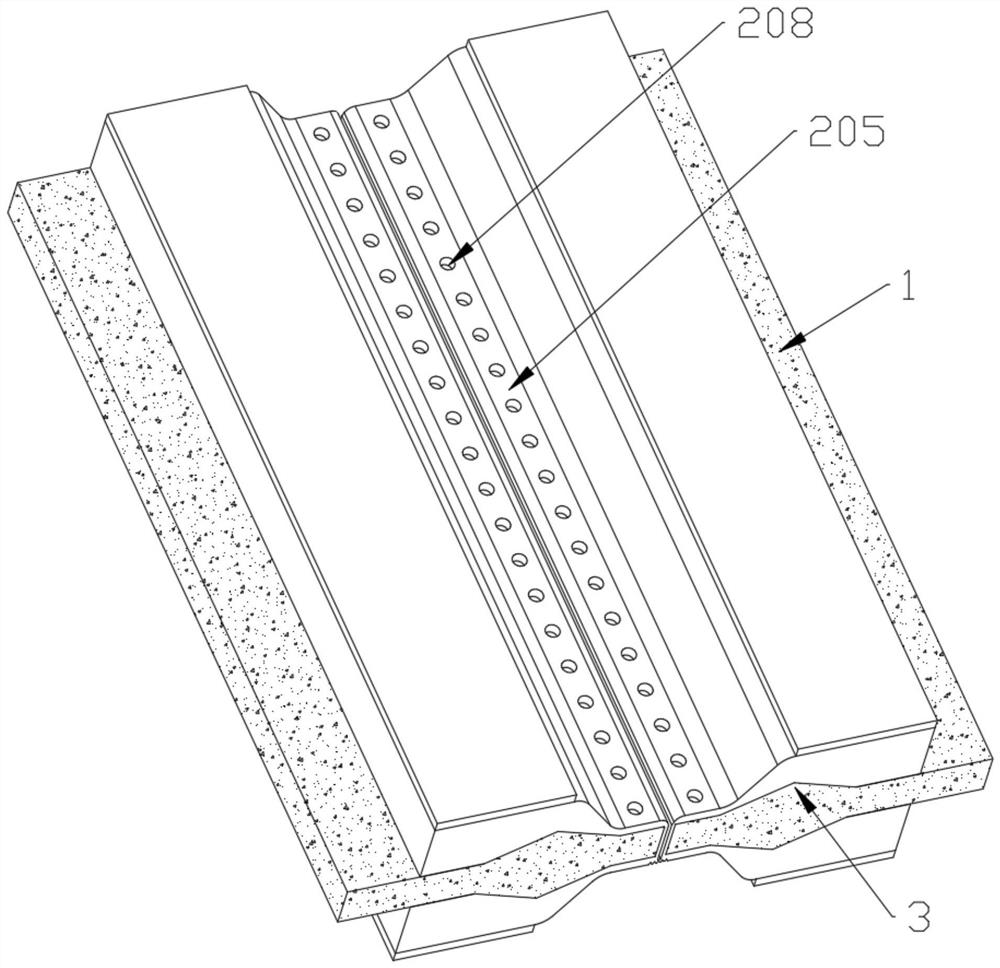

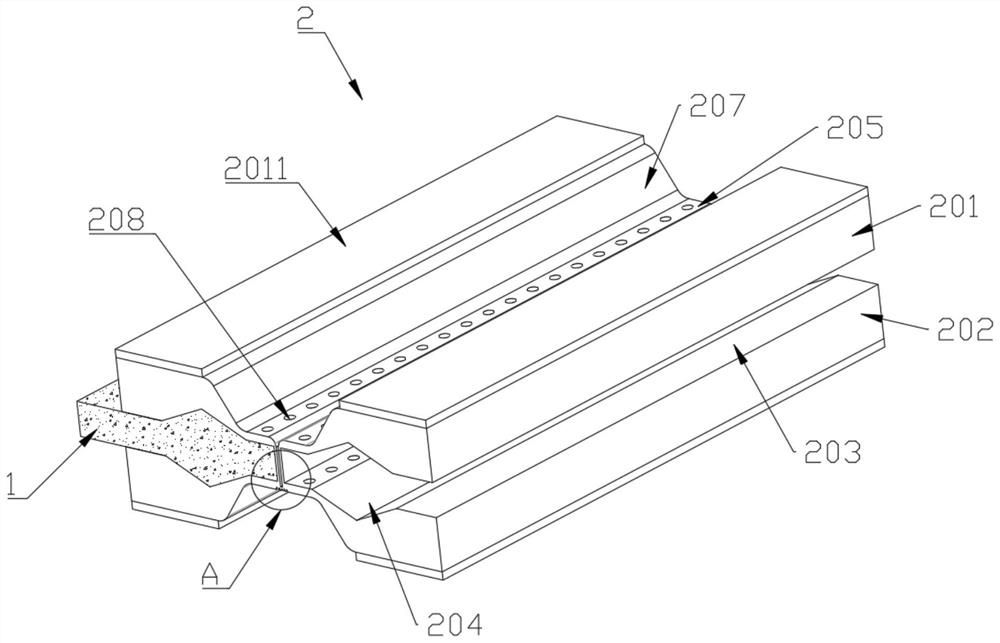

[0037] see Figure 1-Figure 5 , the present invention provides a high-performance power control board, including a power control board 1 and a power control board connector 2 , the power control board connector 2 is fixedly installed on the side of the power control board 1 .

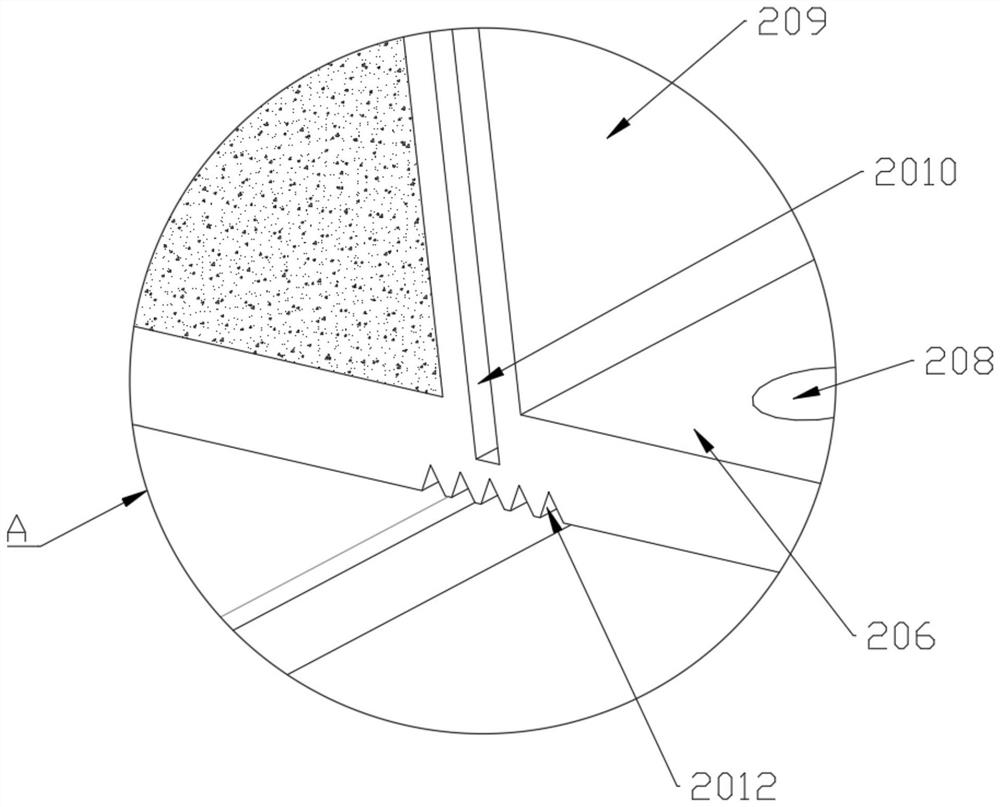

[0038] Specifically, such as Figure 4 As shown, the power control board 1 includes a substrate 101, a bottom copper 102, a solder resist wet film layer 103, a dry film layer 104 and a thick copper layer 105, the substrate 101 is provided with a bottom copper 102, and the bottom copper 102 is coated with a solder resist wet film Layer 103, dry film layer 104 is laminated on solder resist wet film layer 103, thick copper layer 105 is set on bottom copper 102, and layered processing ensures the continuity of transmission, improves protection ability, and reduces the risk of seepage plating.

[0039] Specifically, such as figure 1 , figure 2 and image 3 As shown, the power control board connector 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com