Polycarbonate resin composition

A technology of polycarbonate resin and resin composition, applied in the field of polycarbonate resin composition and optical components, capable of solving insufficient impact strength, heat resistance and anisotropy, insufficient anisotropy, impact strength and heat resistance reduction, etc., to achieve the effect of suppressing the reduction of optical properties, excellent rigidity and impact resistance, and improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

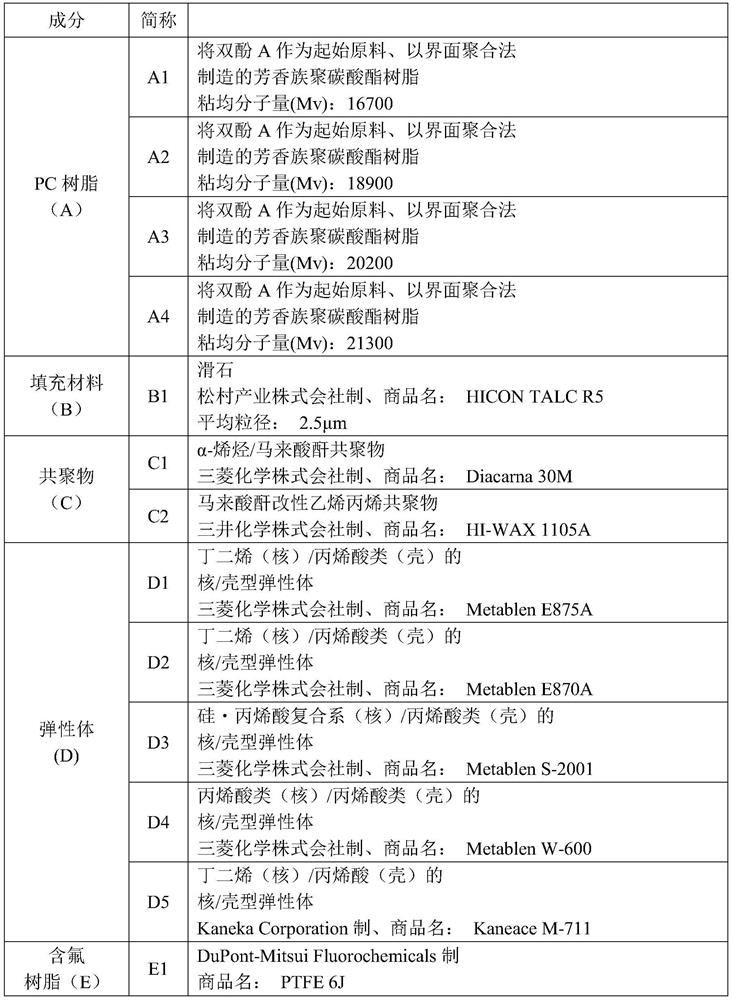

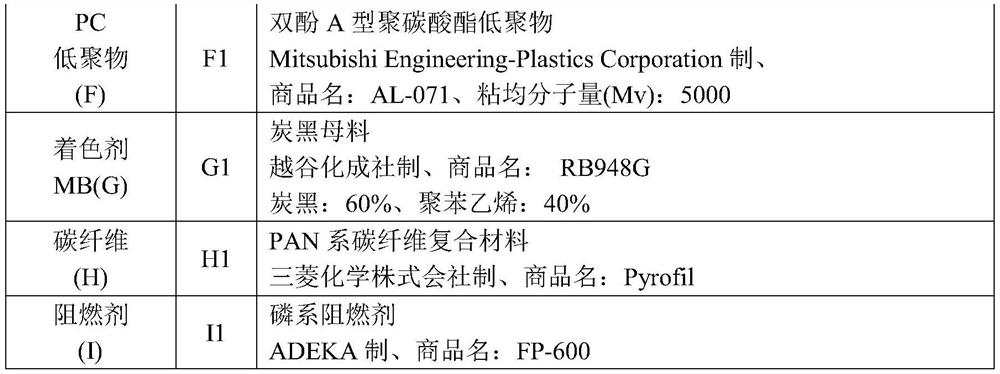

[0236] (Examples 1-11, Comparative Examples 1-11)

[0237] [Manufacture of resin composition pellets]

[0238] The above-mentioned components were blended at the ratios described in Table 2-3 (all parts by mass), uniformly mixed in a tumble mixer, fed from a hopper to an extruder, and melt-kneaded.

[0239] As an extruder, a twin-screw extruder (TEX25αIII, L / D=52.5) manufactured by Nippon Steel Works Co., Ltd. was used, and melt extrusion was carried out under the conditions of a screw speed of 200 rpm, a barrel temperature of 280° C., and a discharge rate of 25 kg / hour. out. The extruded strands are quenched in a water tank and pelletized with a pelletizer.

[0240] After drying the pellets obtained in the above-mentioned production method at 120° C. for 5 hours, the NEX80 injection molding machine manufactured by Nissei Plastic Industry Co., Ltd. was used at a temperature of 280° C. Under the condition of a pressure of 90 MPa, it was molded into a molded product of an I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com