Manufacture of multilayer ceramic structures from continuous filaments of different compositions

A multi-layer ceramic and continuous fiber technology, which is applied in the direction of ceramic layered products, layered products, antennas, etc., can solve the problems of micro-cracks and layers, hindering the progress of manufacturing ceramic broadband radomes, and avoiding low productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

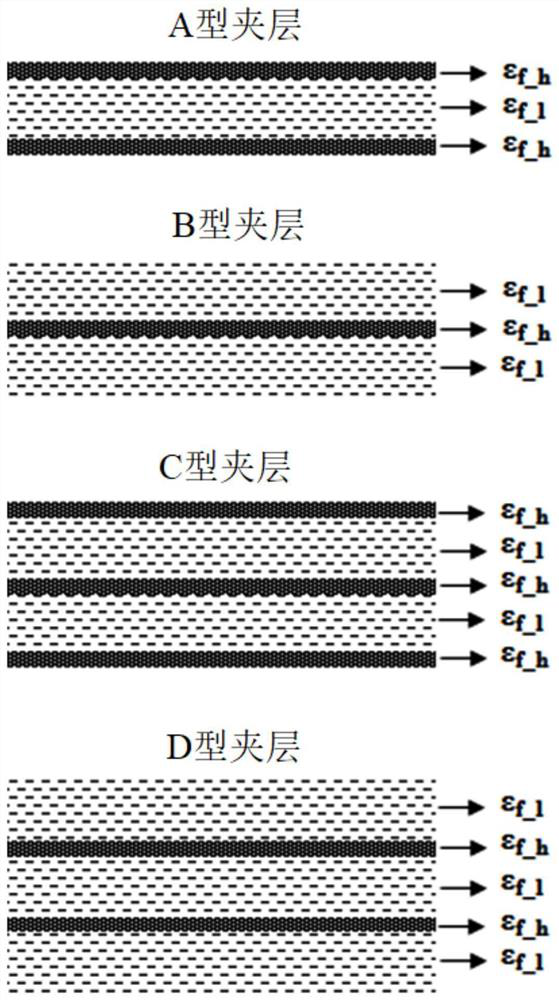

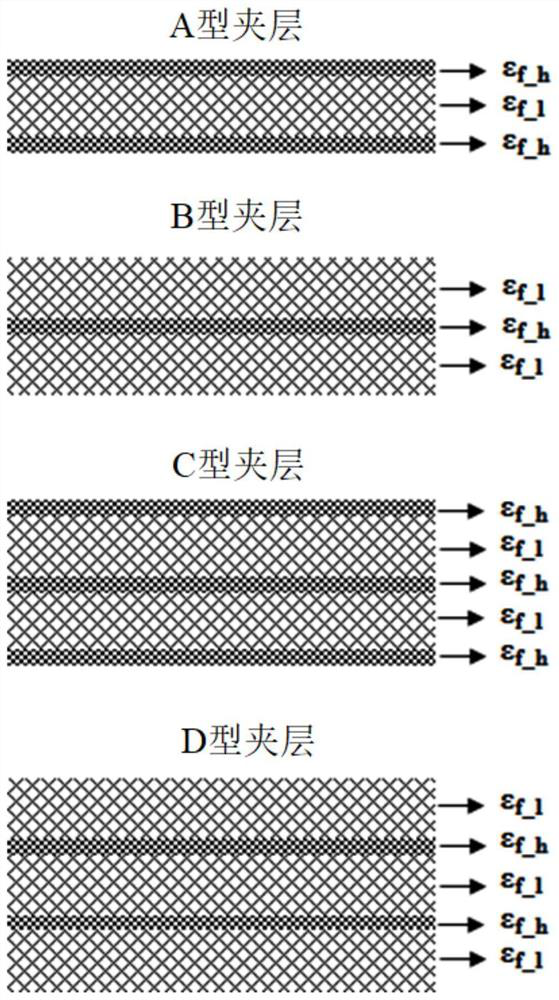

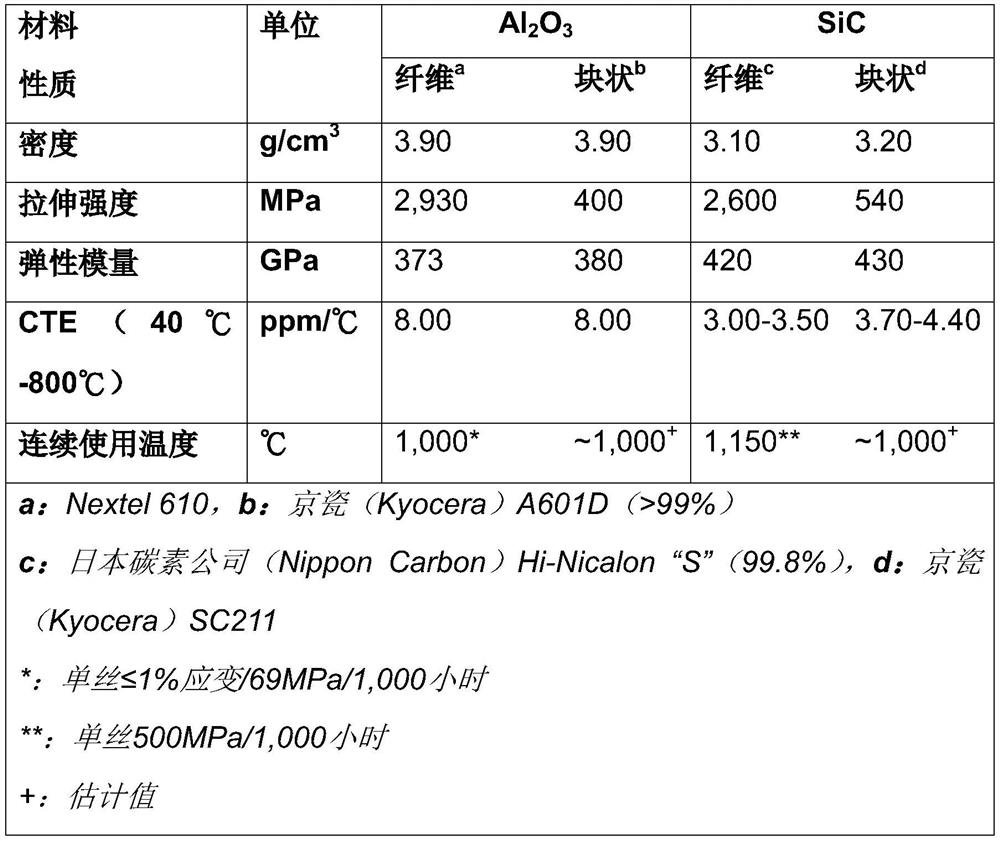

[0027] Fiber-reinforced ceramic matrix composites (FR-CMCs) are advanced and customizable materials with improved toughness and damage tolerance compared to bulk ceramics [6]. Broadly speaking, reinforcing fibers can be divided into inorganic fibers and organic fibers [4]. Inorganic fibers can be further divided into non-metal fibers and metal fibers, while organic fibers are mainly carbon fibers and polymer fibers. Ceramic fibers belong to the same family of non-metallic inorganic fibers as glass / mineral and single crystal fibers [4].

[0028] Fiber material selection for CMC applications is critical. Temperatures on the radome material are known to be as high as 1,000°C during high Mach number flight, limiting the choice of fiber material. Polymers and glass fibers have degradation temperatures of 500 °C and 700 °C, respectively, which limits their effective use in CMCs at higher temperatures [6]. Therefore, ceramic fibers are a right choice to support high-performance CM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com