Rapid containerization cultivation method for big trees for engineering

A cultivation method and large tree technology, applied in the field of arboriculture, can solve the problems of limited cultivation time, long seedling cultivation period, and difficulty in pilling, etc., and achieve reduced maintenance and management costs, good root growth conditions, and reduced root growth. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Use the present invention to plant a batch of osmanthus trees needed for a project in a certain area of Hangzhou, requiring a diameter at breast height of more than 12cm, and the expected cultivation period is about 9 years.

[0022] The soilless cultivation substrate is prepared by fully stirring the following raw materials according to the volume ratio: 30% pine scales; 25% peat; 15% fermented bamboo powder; 20% sandstone; 5% straw crumbs; 5% organic fertilizer.

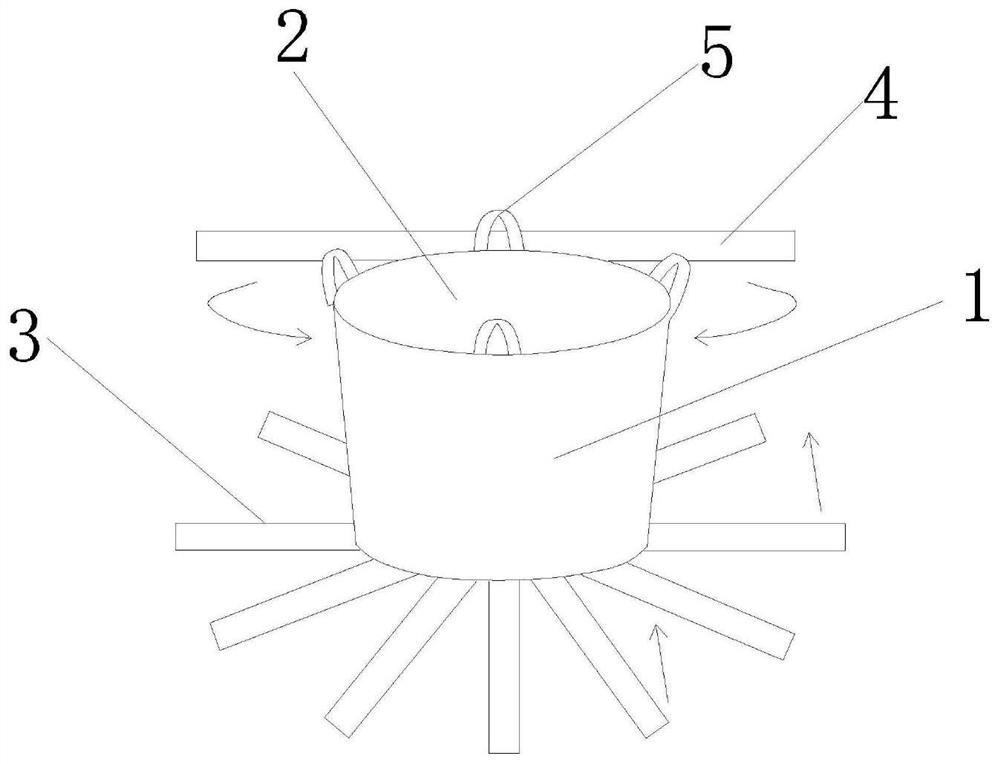

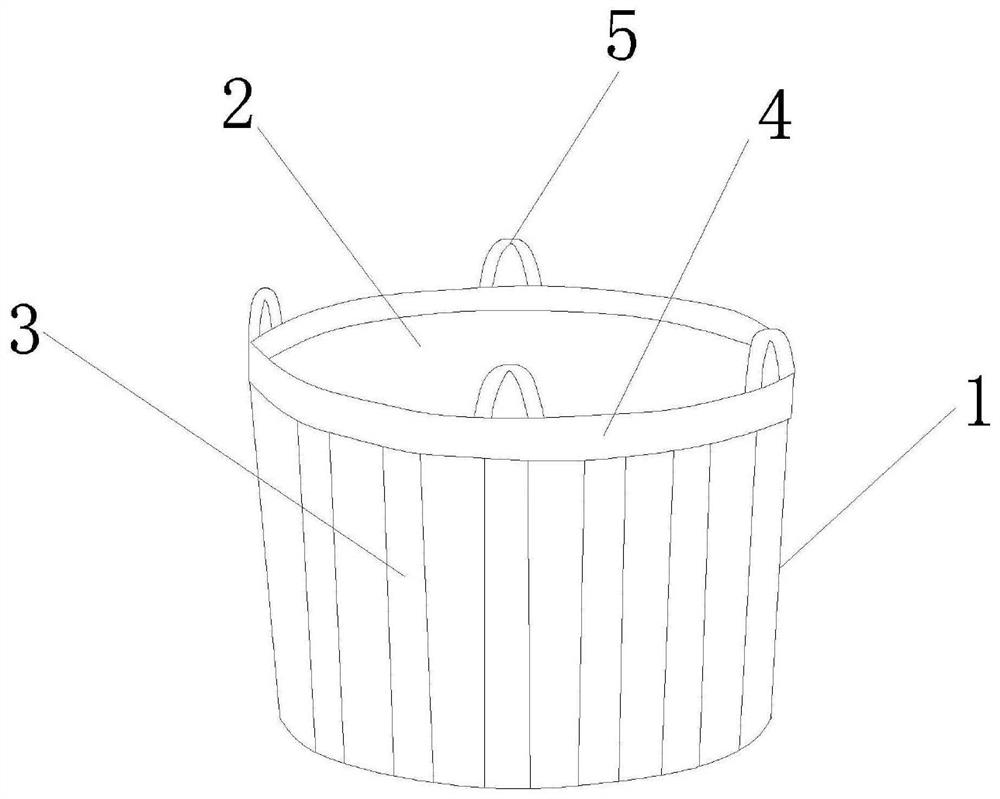

[0023] To process the planting bag, choose a beautiful planting bag 1 with a height of caliber 80cm, a height of 55cm, and a gram weight of 400g. The bag is covered with a piece of nylon mesh 2, and 6 longitudinal polyester woven cloth belts 3 are taken outside the bag to form the word "rice". Type placement, from the middle position of the bottom to wrap the beauty planting bag 1 vertically upwards, use a horizontal polyester woven cloth belt 4 along the bag mouth to wrap the nylon mesh 2, the vertical pol...

Embodiment 2

[0027] Use the present invention to plant a batch of big-leaved holly trees in a certain area in Hangzhou, and the expected cultivation period is about 10 years.

[0028] The soilless cultivation substrate is prepared by fully stirring the following raw materials according to the volume ratio: 30% of pine scales; 30% of peat; 15% of fermented bamboo powder; 15% of sand and stone; 5% of straw granules;

[0029]To process the planting bag, choose a beautiful planting bag 1 with a height of 80cm in diameter, a height of 60cm, and a gram weight of 420g. The bag is covered with a piece of nylon mesh 2, and 6 longitudinal polyester woven cloth belts 3 are taken outside the bag to form the word "rice". Type placement, from the middle position of the bottom to wrap the beauty planting bag 1 vertically upwards, use a horizontal polyester woven cloth belt 4 along the bag mouth to wrap the nylon mesh 2, the vertical polyester woven cloth belt 3 and the 4 beauty planting bags 1 The bag ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com