Method for improving large-size monocrystal diamond joint quality

A single crystal diamond, large-size technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of large cracks at the splicing place and poor quality of the splicing area, so as to achieve faster lateral growth and seamless The effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

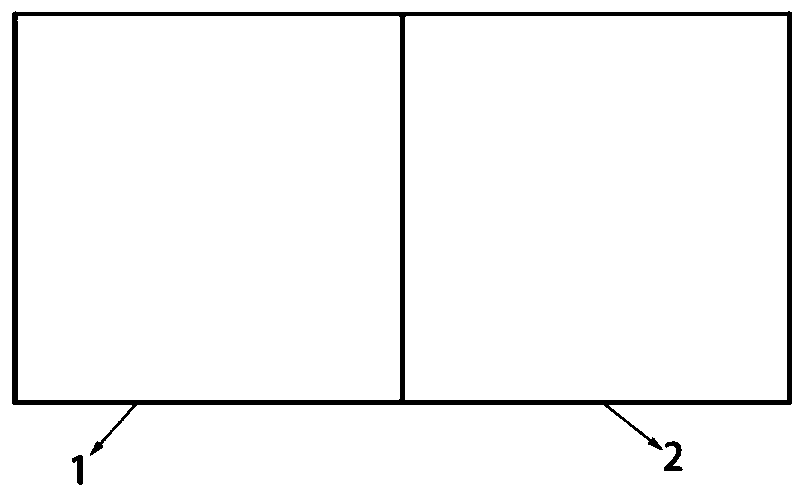

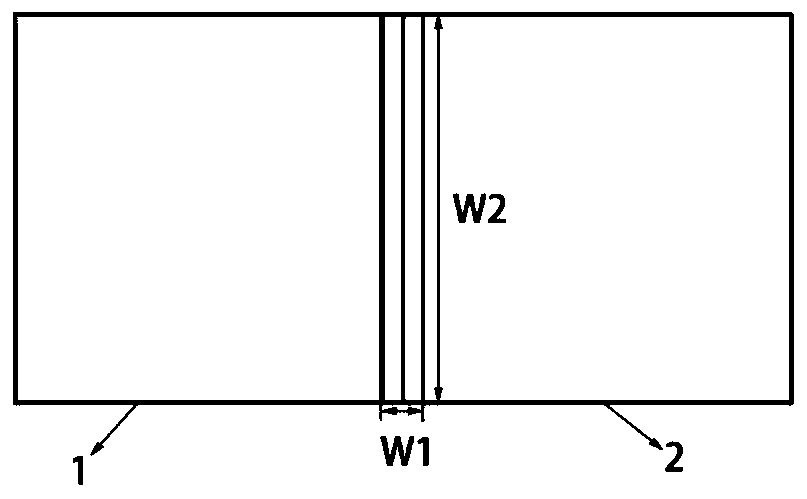

[0042] The method of splicing and growing large-size and high-quality single-crystal diamond by laser grooving has the following steps:

[0043] Two pieces of single crystal diamond with side orientation of (100) are selected, the size is 4×4×1mm 3 and 4×4×1mm 3 , and at the same time use paraffin wax to inlay on the grinding workpiece, grind their surface and splicing side, and use diamond grinding powder with particle size of W40, W20, W10, W5 to grind for 1 hour, so that the grinding surface of two single crystal diamonds is smooth and has a same thickness. Carry out mechanical polishing on the ground surface and side, first use a load of 200 for 5 minutes, then increase the load to 600, polish for 10 minutes, and finally use a load of 400, polish for 10 minutes, the height difference after polishing is 5 μm, and the surface roughness is 0.3nm; use sulfuric acid and nitric acid 5:1 volume ratio to pickle the polished sample for 30 minutes, and then use acetone and absolut...

Embodiment 2

[0045] The method of splicing and growing large-size and high-quality single-crystal diamond by laser grooving has the following steps:

[0046] Two pieces of single crystal diamond with side orientation of (100) are selected, and the size is 8×8×1mm 3 and 8×8×1mm 3 , and at the same time use paraffin wax to inlay on the grinding workpiece, grind their surface and splicing side, and use diamond grinding powder with particle size of W40, W20, W10, W5 to grind for 1 hour, so that the grinding surface of two single crystal diamonds is smooth and has a same thickness. The polished surface and side are mechanically polished, first using a load of 400 for 5 minutes, then increasing the load to 600, polishing for 10 minutes, and finally using a load of 400, polishing for 10 minutes, the height difference after polishing is 8 μm, and the surface roughness is 0.6nm; use sulfuric acid and nitric acid at a volume ratio of 5:1 to pickle the polished sample for 60 minutes, and then use a...

Embodiment 3

[0048] The method of splicing and growing large-size and high-quality single-crystal diamond by laser grooving has the following steps:

[0049] Select two single crystal diamonds with side orientation of (110), the size is 4×4×1mm 3 and 4×4×1mm 3 , and at the same time use paraffin to inlay the grinding workpieces, grind their surfaces and splicing sides, and use diamond grinding powders with particle sizes of W40, W20, W10, and W5 to grind for 2 hours, so that the grinding surfaces of two single crystal diamonds are smooth and have a same thickness. The ground surface and side are mechanically polished, first using a load of 400 for 5 minutes, then increasing the load to 800, polishing for 10 minutes, and finally using a load of 400, polishing for 10 minutes, the height difference after polishing is 9 μm, and the surface roughness is 1nm; use sulfuric acid and nitric acid 5:1 volume ratio to pickle the polished sample for 60min, then use acetone and absolute ethanol to ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com