Iodine-doped derivative porous carbon composite material and preparation method thereof

A composite material, porous carbon technology, used in the preparation/purification of carbon, iodine, iodine/hydrogen iodide, etc., can solve the problems of poor electrical conductivity and poor thermal stability, achieve good electrical conductivity, improve electrical conductivity, and cheap raw materials easy-to-get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

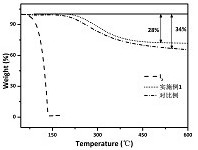

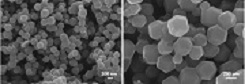

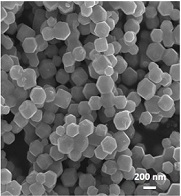

[0041] This embodiment provides a ZPC / I 2 Methods of preparation of composite materials.

[0042] First take 2.68 g of Zn(NO 3 ) 2 •6H 2O and 0.66 g of 2-methylimidazole were respectively dissolved in 100 mL of methanol, and stirred vigorously for 15 minutes to form a solution; then the two solutions were mixed, stirred at room temperature for 1 hour and then allowed to stand for 12 hours; the centrifuged white The crystals were washed several times with methanol and then dried at 60°C for 12 hours. The synthesized ZIF-8 product was placed in N 2 In the atmosphere, the calcination temperature is 900° C., and the heating rate is 5° C. / min. After 4 hours of calcination, ZPC is obtained. Disperse pure iodine in an ethanol solution, then add ZPC to the solution, and control the weight ratio of iodine and ZPC to 1:1; next, dry and volatilize the product at 40°C to remove ethanol, and then dry and volatilize the product at 130°C in an Ar atmosphere Heating; finally heating at ...

Embodiment 2

[0044] This embodiment provides a ZPC / I 2 Methods of preparation of composite materials.

[0045] First take 2.56 g of Zn(NO 3 ) 2 •6H 2 O and 0.63 g of 2-methylimidazole were dissolved in 100 mL of methanol respectively, and stirred vigorously for 15 minutes to form a solution; then the two solutions were mixed, stirred at room temperature for 1 hour and then allowed to stand for 12 hours; the centrifuged white The crystals were washed several times with methanol and then dried at 60°C for 12 hours. The synthesized ZIF-8 product was placed in N 2 In the atmosphere, the calcination temperature is 800° C., the heating rate is 5° C. / min, and the ZPC is obtained after 4 hours of calcination. Disperse pure iodine in ethylene glycol solution, then add ZPC to the solution, and control the weight ratio of iodine and ZPC to 1:2; next, dry and volatilize the product at 40°C to remove ethanol, and then place it in an Ar atmosphere at 130 Heating at ℃; finally heating at 100℃ in ai...

Embodiment 3

[0047] This embodiment provides a ZPC / I 2 Methods of preparation of composite materials.

[0048] First take 2.73 g of Zn(NO 3 ) 2 •6H 2 O and 0.69 g of 2-methylimidazole were respectively dissolved in 100 mL of methanol, and stirred vigorously for 15 minutes to form a solution; then the two solutions were mixed, stirred at room temperature for 1 hour and then allowed to stand for 12 hours; the centrifuged white The crystals were washed several times with methanol and then dried at 60°C for 12 hours. The synthesized ZIF-8 product was placed in N 2 In the atmosphere, the calcination temperature is 900° C., and the heating rate is 5° C. / min. After 6 hours of calcination, ZPC is obtained. Disperse pure iodine in ethanol solution, then add ZPC to the solution, and control the weight ratio of iodine and ZPC to 1:2; next, dry and volatilize the product at 40°C to remove ethanol, and then dry and volatilize the product at 130°C in an Ar atmosphere Heating; finally heating at 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com