Urethane acrylate with NCO reactive group and UV (ultraviolet) moisture curing adhesive with resin

A polyurethane acrylate and reactive group technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of low bonding strength, insufficient initial adhesion and adhesion, and curing depth Shallow and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

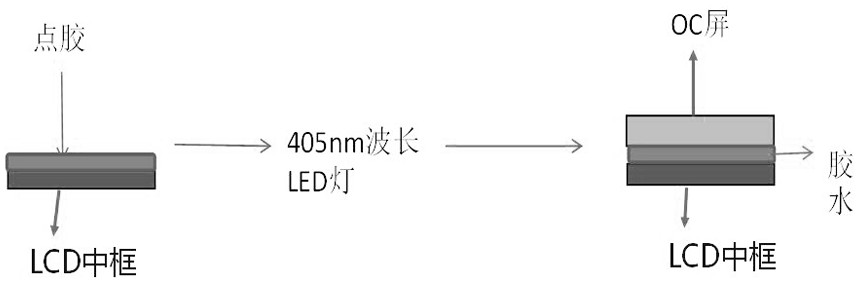

Image

Examples

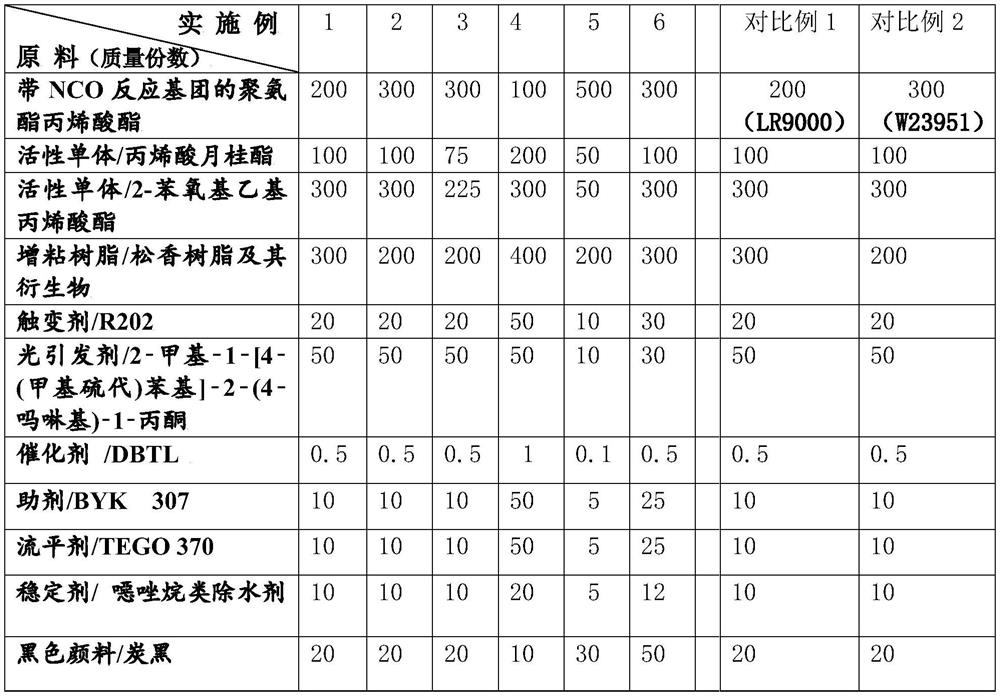

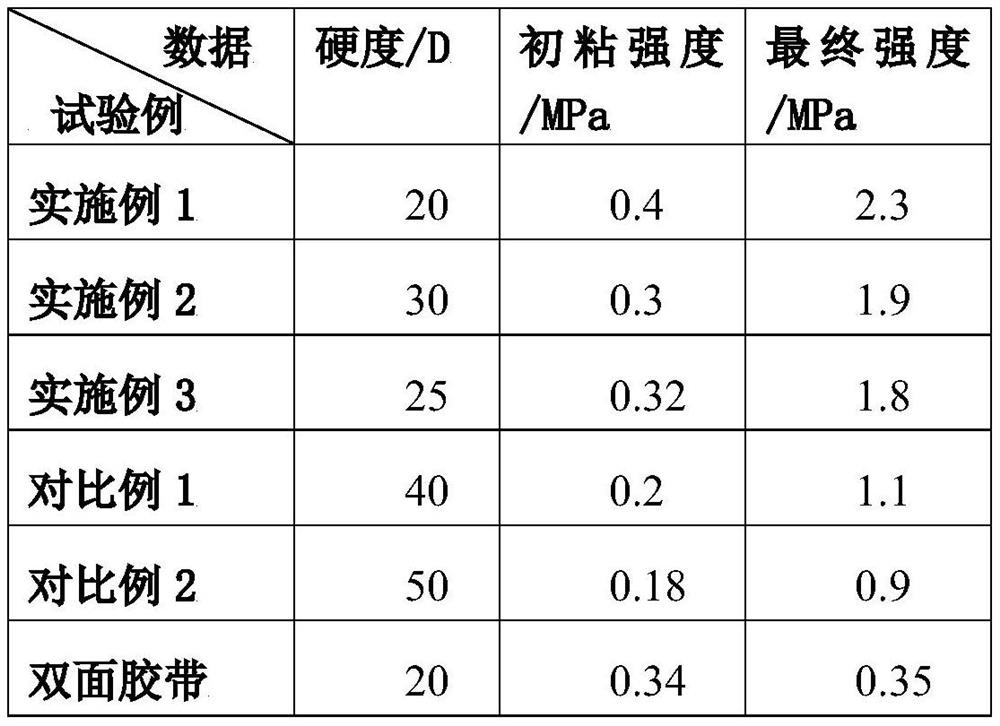

Embodiment 1

[0039] Step 1. Mix 300 parts of tackifying resin and 400 parts of active monomer into the reaction kettle, heat to a certain temperature and mix evenly, vacuumize and stir until clarified.

[0040] Step 2. After cooling down to room temperature, add 200 parts of urethane acrylate with NCO reactive groups into the reactor, vacuumize for a period of time, add 50 parts of photoinitiator and stir until uniform.

[0041] Step 3. Dry 20 parts of thixotropic agent in an oven at 120°C for 2-3 hours and add to the reaction kettle. Finally, add 20 parts of carbon black, 10 parts of defoamer, 10 parts of leveling agent, dibutyltin dilaurate (DBTL) 0.5 parts, 10 parts of oxazolidine water-removing agents, vacuum-stirred, and discharged under vacuum conditions to obtain the pressure-sensitive UV / moisture-curable adhesive of the present invention.

Embodiment 2

[0043] The preparation steps and conditions are the same as in Example 1. Just reduce the tackifying resin to 200 parts, increase the urethane acrylate with NCO reactive group to 300 parts, and use the same amount of other raw materials to obtain the pressure-sensitive UV / moisture-cured product of the present invention. adhesive.

Embodiment 3

[0045] The preparation steps and conditions are the same as in Example 1. Just reduce the active monomer to 300 parts, reduce the tackifying resin to 200 parts, increase the urethane acrylate with NCO reactive group to 300 parts, and keep other conditions unchanged, to obtain the pressure-sensitive adhesive of the present invention. Non-toxic UV / moisture curing adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com