Furnace slag melting agent and application method thereof in refining high-purity ultrahigh manganese steel

A technology of slag agent and high manganese, which is applied in the field of furnace slag agent and refining high-purity ultra-high manganese steel, which can solve the problems of poor effect of harmful gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

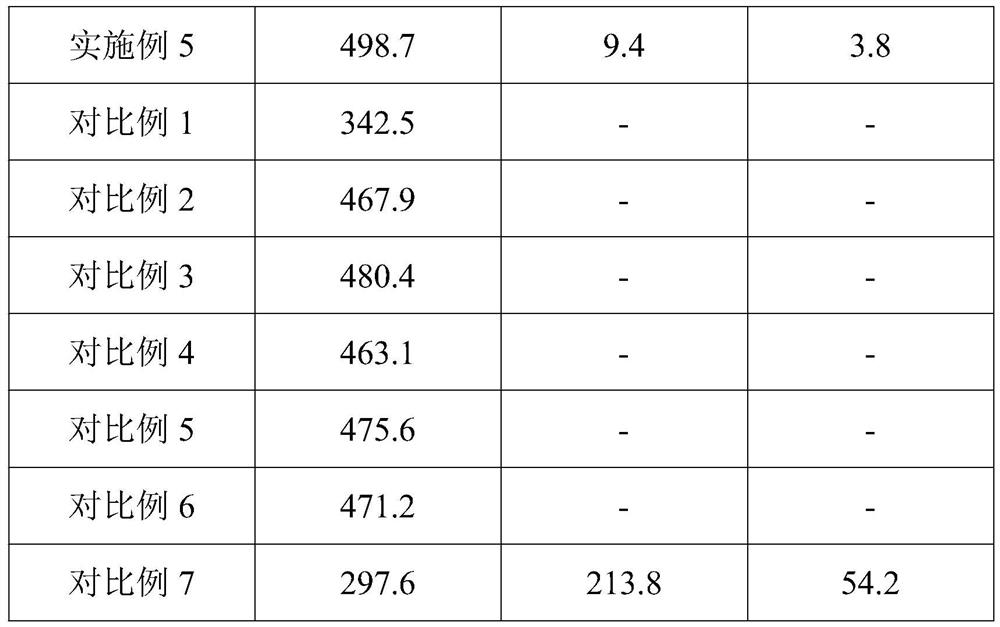

Examples

Embodiment 1

[0028] A furnace slag agent, in parts by weight, comprising the following raw materials: 22 parts of lime powder, 13 parts of activated clay powder, 7 parts of montmorillonite powder, 16 parts of calcium aluminate powder, 9 parts of barium carbonate powder, yttrium oxide powder 4 parts, 8 parts of fluorite powder, 10 parts of wollastonite powder, 13 parts of medical stone powder;

[0029] The particle size of described lime powder is 600 orders;

[0030] The particle size of described activated clay powder is 900 orders;

[0031] The particle size of described montmorillonite powder is 800 orders;

[0032] The particle size of described calcium aluminate powder is 800 orders;

[0033] The particle size of described barium carbonate powder is 700 orders;

[0034] The particle size of described yttrium oxide powder is 900 orders;

[0035] The particle size of the fluorite powder is 800 mesh;

[0036] The particle size of described wollastonite powder is 900 orders;

[0037...

Embodiment 2

[0045] A furnace slag agent, in parts by weight, comprising the following raw materials: 28 parts of lime powder, 16 parts of activated clay powder, 8 parts of montmorillonite powder, 18 parts of calcium aluminate powder, 9 parts of barium carbonate powder, yttrium oxide powder 5 parts, 9 parts of fluorite powder, 10 parts of wollastonite powder, 14 parts of medical stone powder;

[0046] The particle size of described lime powder is 800 orders;

[0047] The particle size of described activated clay powder is 800 orders;

[0048] The particle size of described montmorillonite powder is 800 orders;

[0049] The particle size of described calcium aluminate powder is 900 orders;

[0050] The particle size of described barium carbonate powder is 1000 orders;

[0051] The particle size of described yttrium oxide powder is 1000 orders;

[0052]The particle size of the fluorite powder is 900 mesh;

[0053] The particle size of described wollastonite powder is 900 orders;

[005...

Embodiment 3

[0062] A furnace slag agent, in parts by weight, comprising the following raw materials: 32 parts of lime powder, 18 parts of activated clay powder, 9 parts of montmorillonite powder, 20 parts of calcium aluminate powder, 12 parts of barium carbonate powder, yttrium oxide powder 5 parts, 10 parts of fluorite powder, 11 parts of wollastonite powder, 15 parts of medical stone powder;

[0063] The particle size of described lime powder is 700 orders;

[0064] The particle size of described activated clay powder is 900 orders;

[0065] The particle size of described montmorillonite powder is 900 orders;

[0066] The particle size of described calcium aluminate powder is 800 orders;

[0067] The particle size of described barium carbonate powder is 800 orders;

[0068] The particle size of described yttrium oxide powder is 1000 orders;

[0069] The particle size of the fluorite powder is 900 mesh;

[0070] The particle size of described wollastonite powder is 1000 orders;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com