Acrylate foaming reflector plate, preparation method thereof and backlight module

A technology of acrylate and reflective sheet, which is applied in the direction of optics, optical components, coatings, etc., and can solve problems such as insufficient stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

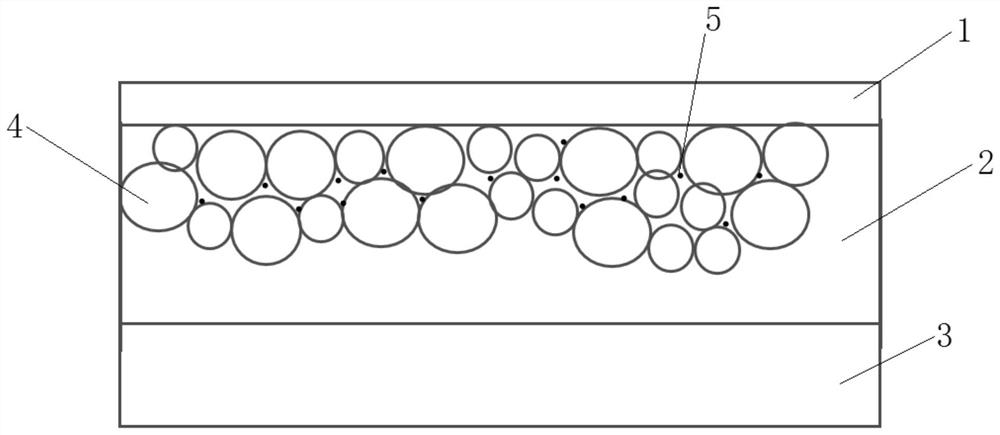

[0044] The present invention also provides a method for preparing an acrylate foam reflective sheet, comprising the following steps:

[0045] A) immersing the porous nanoparticles in a foaming solvent and stirring to obtain porous nanoparticles adsorbed with a foaming solvent;

[0046] Described foaming solvent is one or more in normal heptane and normal hexane;

[0047]B) mixing porous nanoparticles adsorbed with a foaming solvent and UV acrylate resin, coating the surface of the PET substrate, and curing to obtain a foaming layer;

[0048] C) Compounding a protective layer on the surface of the foam layer to obtain an acrylate foam reflective sheet.

[0049] In the present invention, the porous nanoparticles are immersed in the foaming solvent, and the foaming solvent is stirred to fill the pore structure inside of the porous material. In order to avoid the premature volatilization of the adsorbed foaming solvent, the porous nanoparticles adsorbed with the foaming solvent s...

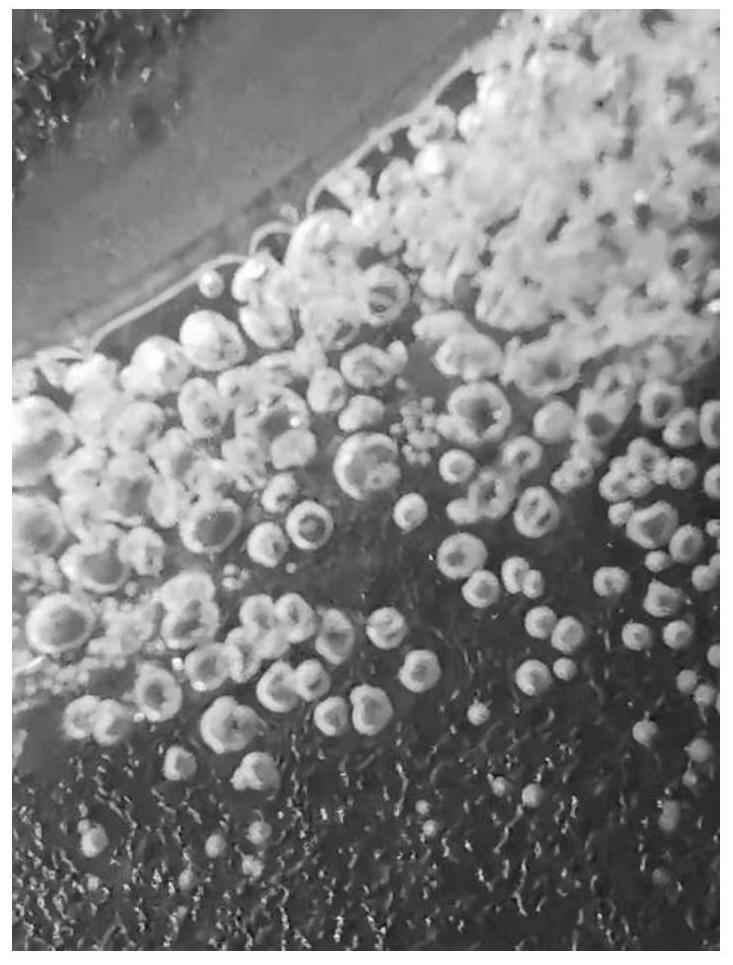

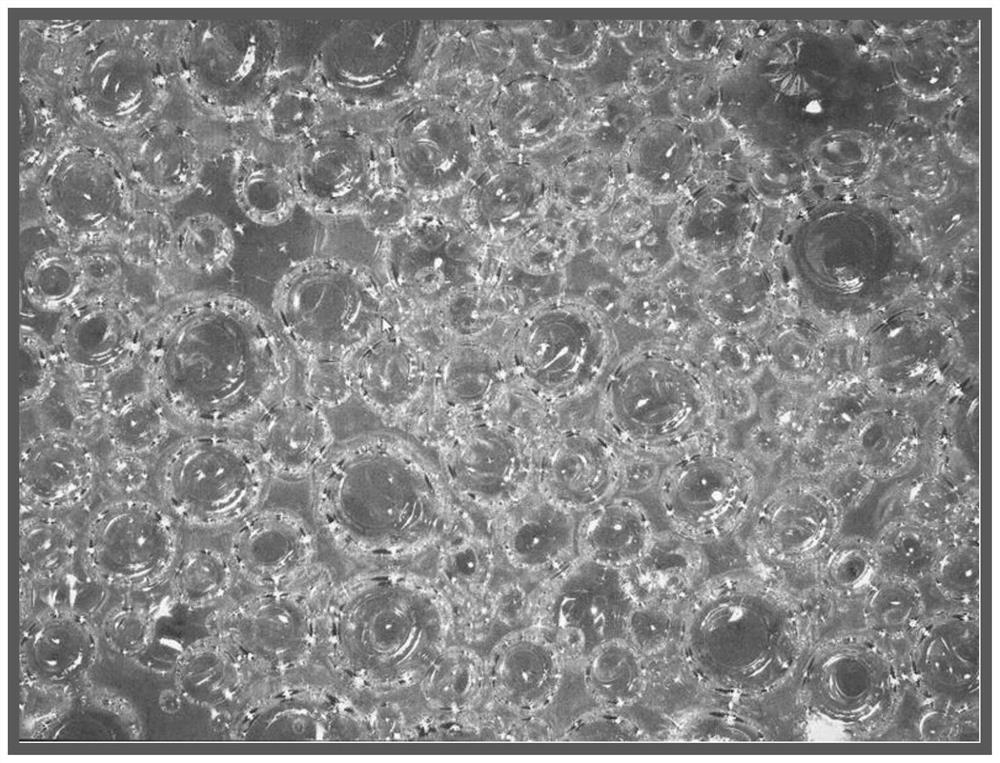

Embodiment 1

[0070] 20g particle size is 20nm, specific surface area is 385m 2 / g SiO 2 , soaked in 50mL of acetone, at room temperature or 20°C, using centrifugal rotation 1800rpm / 10min to speed up the mixing, the mixed SiO 2 Take it out and store it in an environment below 20°C for later use.

[0071] Take 5g of the above mixed SiO 2 , at room temperature or below 20°C, uniformly stirred and dispersed in 50 g of ultraviolet light acrylic resin with a refractive index of 1.562 to obtain a coating liquid.

[0072] Take the 100 μm PET base film, and apply the above coating solution to the surface of the PET base film, the coating machine speed is 10m / m, and the thickness of the coating layer is controlled to 30 μm;

[0073] The curing process is as follows:

[0074] The energy of the first light source is 20mW / cm2 for pre-curing, the light curing wavelength is LED 365nm light source, and the machine speed is 10m / min, so that the porous SiO2 in the UV glue 2 The acetone in the UV glue p...

Embodiment 2~3

[0079] A white reflective sheet was prepared according to the method in Example 1, except that in Examples 2 and 3, acrylic resins with a refractive index of 1.583 and 1.602 were used instead of the acrylic resin with a refractive index of 1.562 in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com