Preparation method of water nutrient for culture of penaeus vannamei boone

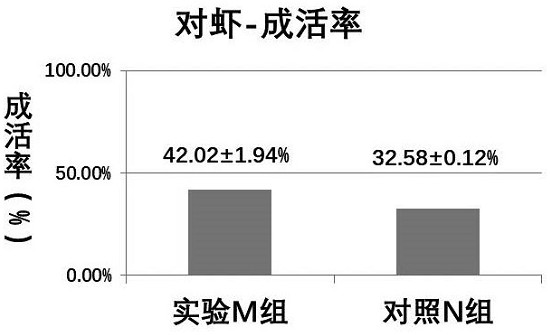

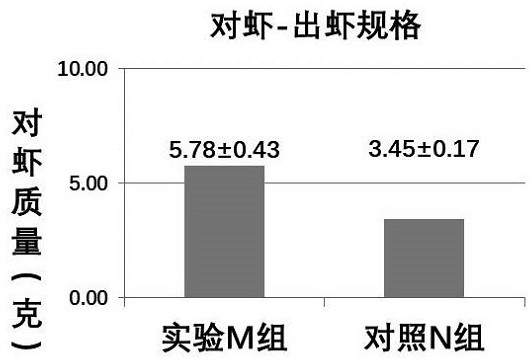

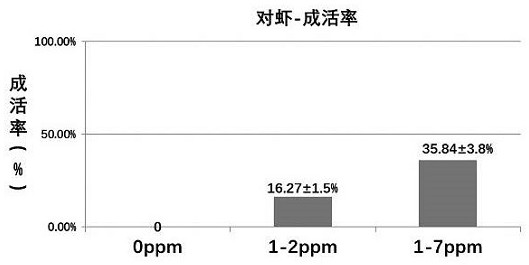

A nutrient and technology of Penaeus vannamei, which is applied in the field of preparation of nutrients in the culture water of Penaeus vannamei, can solve the problems of unknown ingredients, high preparation cost, and insufficient active ingredients, and achieve the effects of low production cost, clear ingredients, and improved survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the water body nutrient used for the cultivation of Penaeus vannamei of the present invention comprises the following steps:

[0019] 1) Dry the shells in the sun, crush the shells into pieces with a crusher, then calcine them in a high-temperature furnace at high temperature, cool them naturally, and weather them into powder;

[0020] 2) Take the powder prepared in step 1), add trace element compounds in proportion, and mix evenly, which is the nutrient solid;

[0021] 3) The nutrient solids: sugarcane molasses: tap water are mixed evenly in proportion, put into a container and sealed for fermentation, and after fermentation, the water body nutrients suitable for the culture of Penaeus vannamei will be obtained.

[0022] In the step 1) the shell is selected from any one of oyster shells and pearl oysters. The preferred shell is oyster shell.

[0023] Said step 1) the broken shell size is 2-5 cm.

[0024] The step 1) the high temperature fur...

Embodiment 1

[0039] In the preparation method of the present invention, oyster shells are purchased, and the oyster shells are exposed to light for 72 hours outdoors. Then the dried oyster shells are preliminarily crushed with an iron hammer, put into a pulverizer and crushed, and sieved to pick out fragments of more than 2 cm for use.

[0040] Take 5 kg of oyster shell fragments, put them into the muffle furnace, close the door of the muffle furnace, adjust the temperature of the muffle furnace to 400 degrees and start the machine for 2 hours. After no smoke comes out, adjust the temperature to 800 degrees and continue to calcine for 3 After 2 hours, turn off the power, open the muffle furnace door to leave a gap in the door to dissipate heat, and fully open the muffle furnace door to cool after 2 hours.

[0041] The calcined pieces of oyster shells are taken out from the muffle furnace, spread flat on the clean ground and naturally weathered, turned during the process, and become powder ...

Embodiment 2

[0046] In the preparation method of the present invention, oyster shells are purchased, and the oyster shells are exposed to light for 72 hours outdoors. Then the dried oyster shells are preliminarily crushed with an iron hammer, put into a pulverizer and crushed, and sieved to pick out fragments of more than 3 cm for use.

[0047] Take 5 kg of oyster shell fragments, put them into the muffle furnace, close the door of the muffle furnace, adjust the temperature of the muffle furnace to 500 degrees and start the machine for 1 hour. After no smoke comes out, adjust the temperature to 800 degrees and continue calcination for 2 After 2 hours, turn off the power, open the muffle furnace door to leave a gap in the door to dissipate heat, and fully open the muffle furnace door to cool after 2 hours.

[0048] The calcined pieces of oyster shells are taken out from the muffle furnace, spread flat on the clean ground and naturally weathered, turned during the process, and become powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com