Intensive care liquid food feeder for internal medicine department

An intensive care and feeder technology, applied in the field of feeders, can solve the problems of patients choking, different concentrations before and after liquid food, affecting patients' absorption and reflux, etc., to reduce pain, facilitate feeding, and improve the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

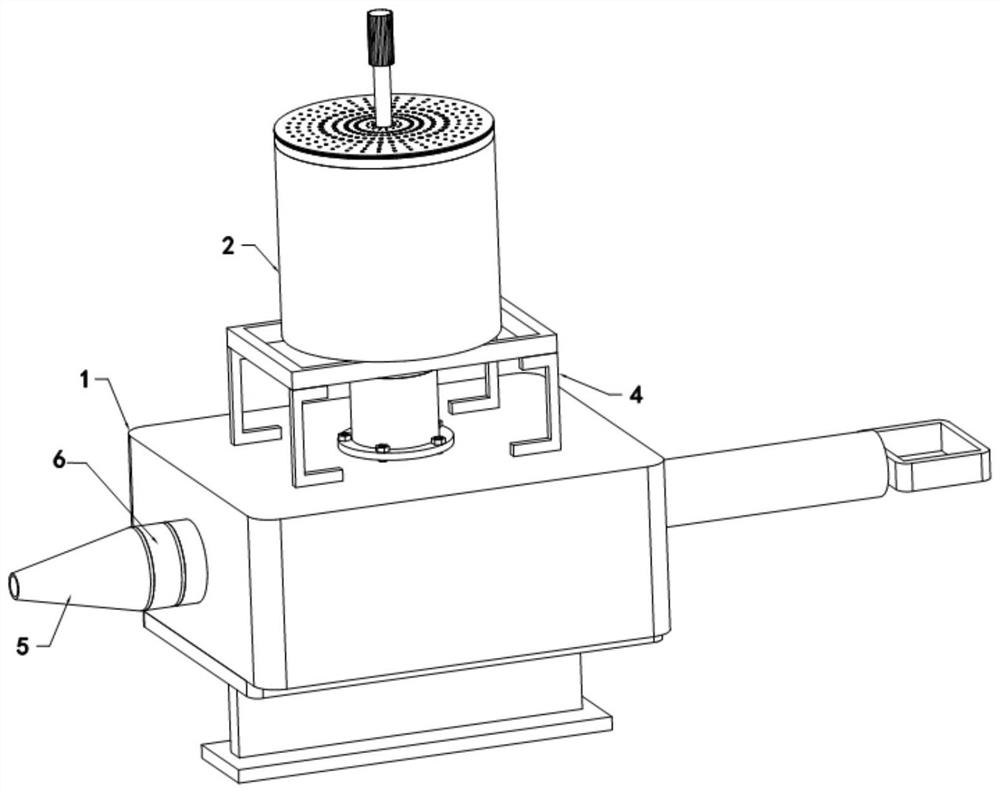

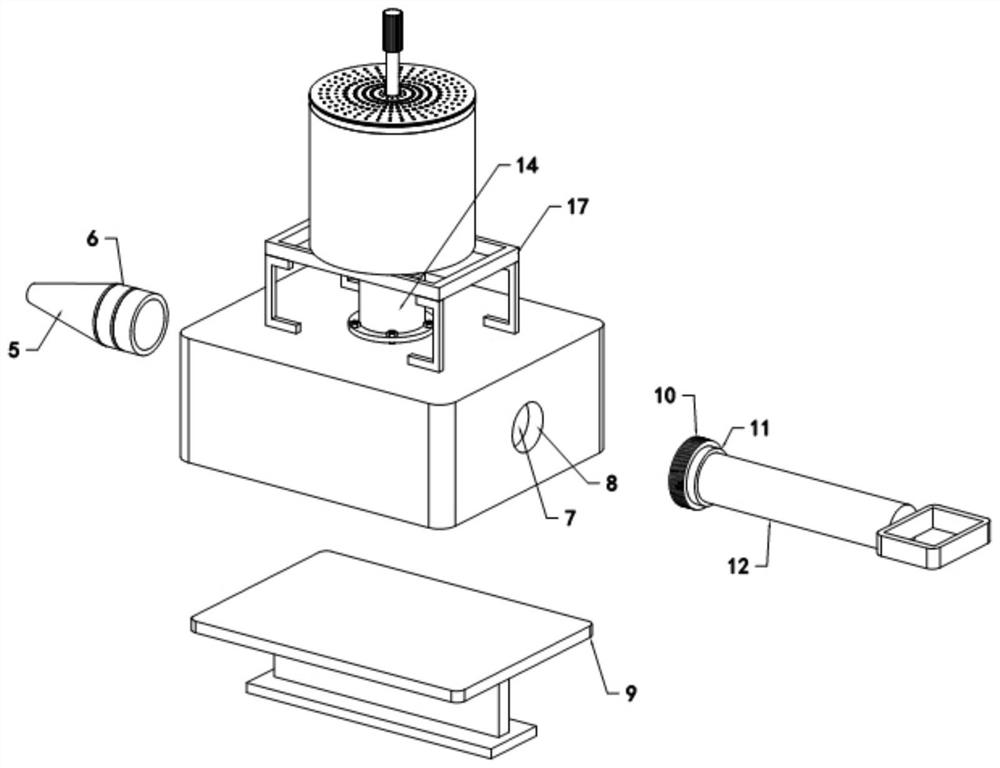

[0028] Such as Figure 1-5 As shown, a flow food feeder for medical intensive care nursing includes a communicating chamber 1, a feeding hole 203 is opened on the top of the communicating chamber 1, and a communicating cavity 7 communicating with the feeding hole 203 is opened on the upper part of the communicating chamber 1, and the two sides of the communicating chamber 1 Each end is provided with a through hole 8 communicating with the communication chamber 7, and the interior of the communication chamber 7 is provided with a piston 10 that is compatible with the communication chamber 7. One end of the communication chamber 1 and the position located at the through hole 8 are detachably connected with an adjustable The other end of the tube 6 communicating with the chamber 1 is horizontally provided with a push rod 12 connected to one side of the piston 10 through the through hole 8 .

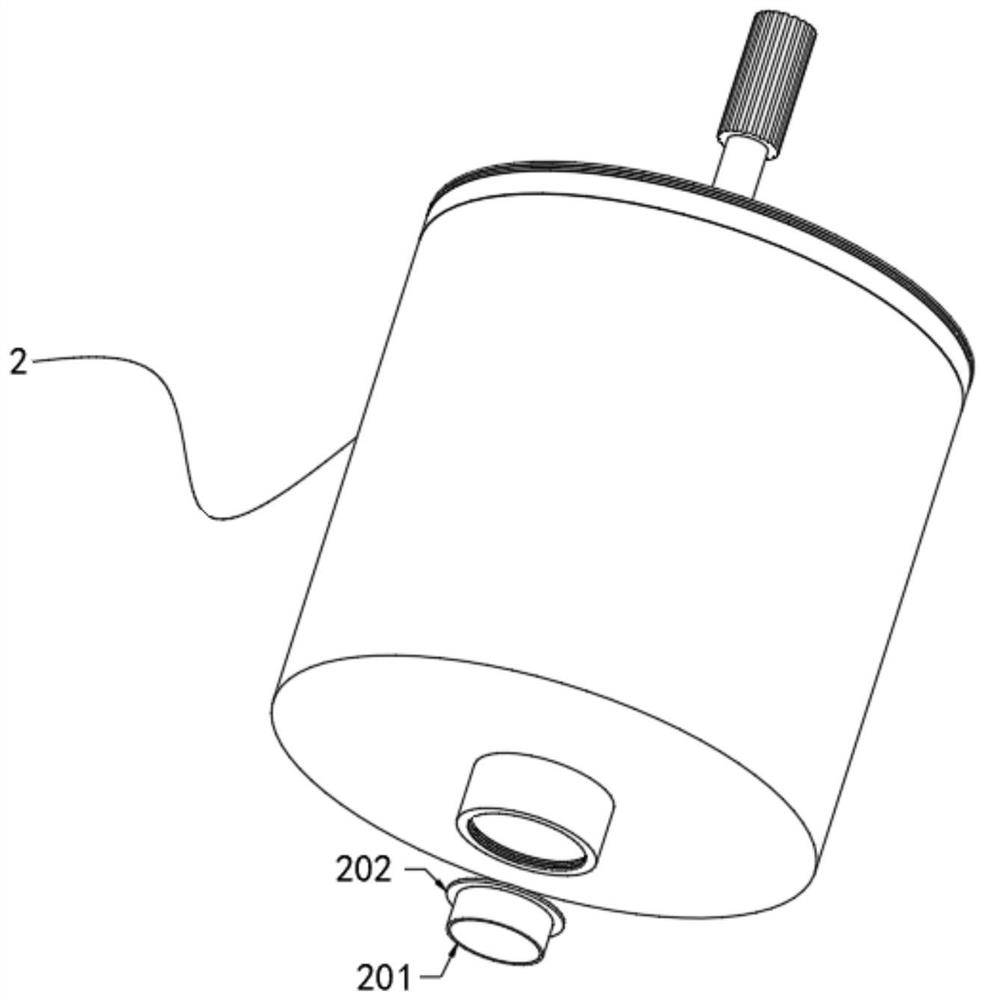

[0029] The top of the communicating chamber 1 is detachably connected with a thermal ins...

Embodiment 2

[0037] In the process of feeding patients with this device, the nurses found that the device still has the following problems: on the one hand, during the feeding process, they are worried that the amount of food will be too much, which will cause the pressure in the stomach of critically ill patients to increase, which is not conducive to digestion and absorption; secondly, In some patients, the pressure in the stomach is relatively high. During the feeding process, factors such as the flow rate of liquid food and the amount of food may cause the patient to vomit and reflux. However, it is difficult to measure the pressure in the patient’s stomach with a manometry device during the feeding process; Furthermore, the liquid food that vomits and regurgitates will flow back along the nasal tube and mix with the liquid food that has not entered the stomach, causing contamination of the liquid food and affecting subsequent feeding; therefore, further improvement of the device is need...

Embodiment 3

[0044] When regurgitation and vomiting occur during the feeding process of critically ill patients, the regurgitated liquid food or gastric juice can be extracted into the connecting cavity 7 through the gastric tube according to the method described in Embodiment 2. In order to prevent contamination of unfed liquid food during the subsequent continuous feeding process, it is necessary to discharge the extracted liquid food or gastric juice, and to ensure the continuity of feeding, the connecting chamber 1 of the device has been improved one step.

[0045] The lower part of the communicating chamber 1 is provided with a backflow chamber 18, and the backflow chamber 18 communicates with the communication chamber 7 through a one-way valve 19; the bottom of the backflow chamber 18 is provided with an underflow valve 13.

[0046] Through the controller, the second current is passed to the electromagnetic part 301, and the electromagnetic part 301 generates a magnetic repulsion forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com