Efficient grinding method for white carbon black production

A grinding method and white carbon black technology, applied in separation methods, chemical instruments and methods, gas treatment and other directions, can solve the problems of dust floating, physical injury of staff, high price, etc., to improve the effect of dust removal and filtration, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] A high-efficiency grinding method based on white carbon black production, comprising the following steps:

[0039] S1, adding a specific aromatic chain active agent into a certain amount of absolute ethanol solution to obtain an active agent ethanol solution;

[0040] S2. Add the prepared active agent ethanol solution dropwise to the white carbon black blank at a uniform speed, and grind it with a grinding device;

[0041] S3, extract the white carbon black powder semi-finished product obtained by grinding with ethanol solution in a fat extractor, and remove the active agent;

[0042] S4. Drying the extracted white carbon black powder semi-finished product in an oven to remove excess water to obtain a white carbon black powder finished product.

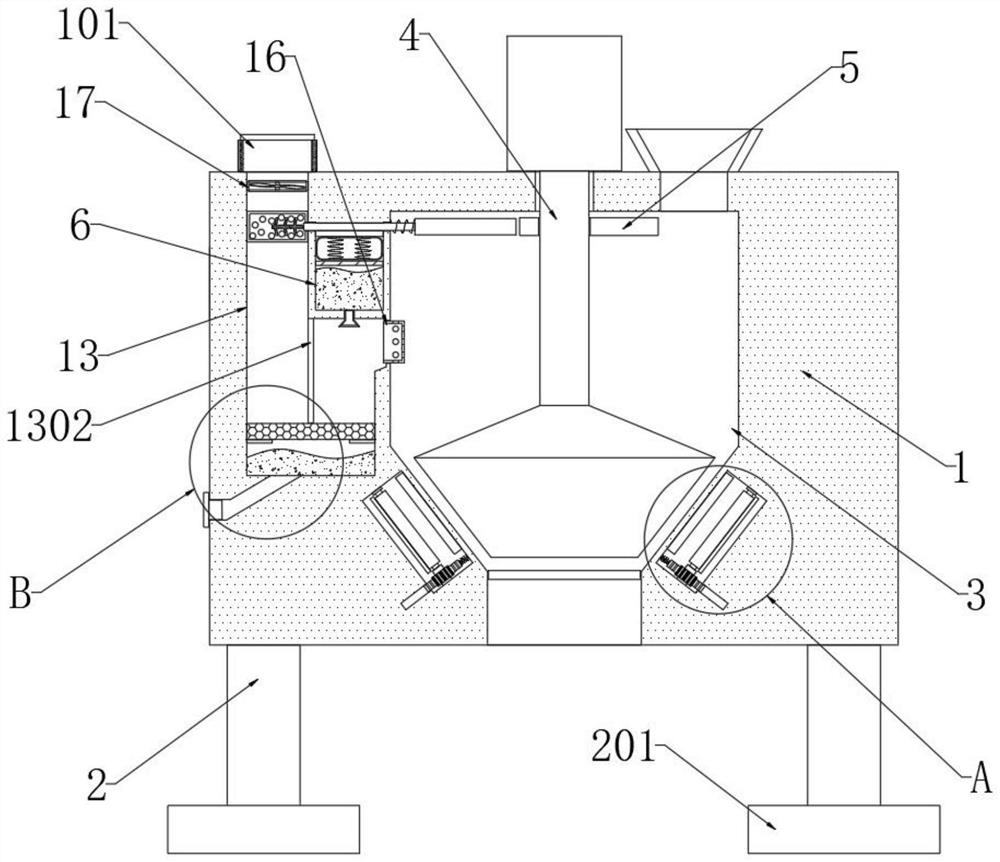

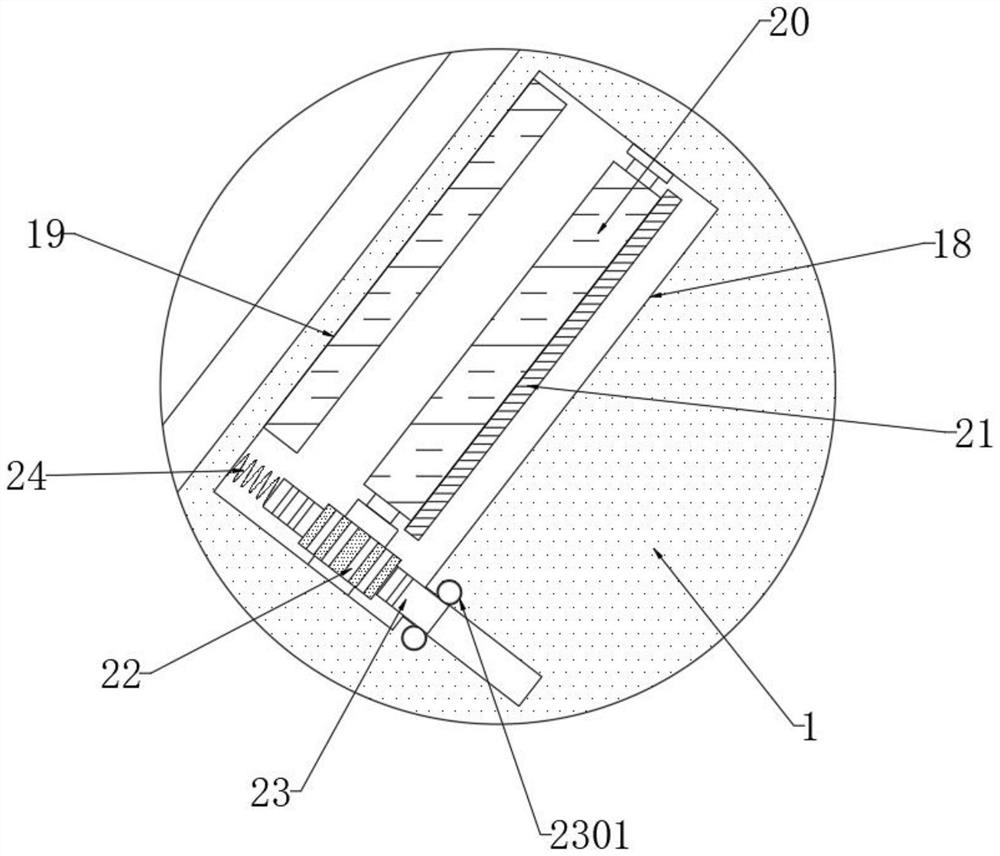

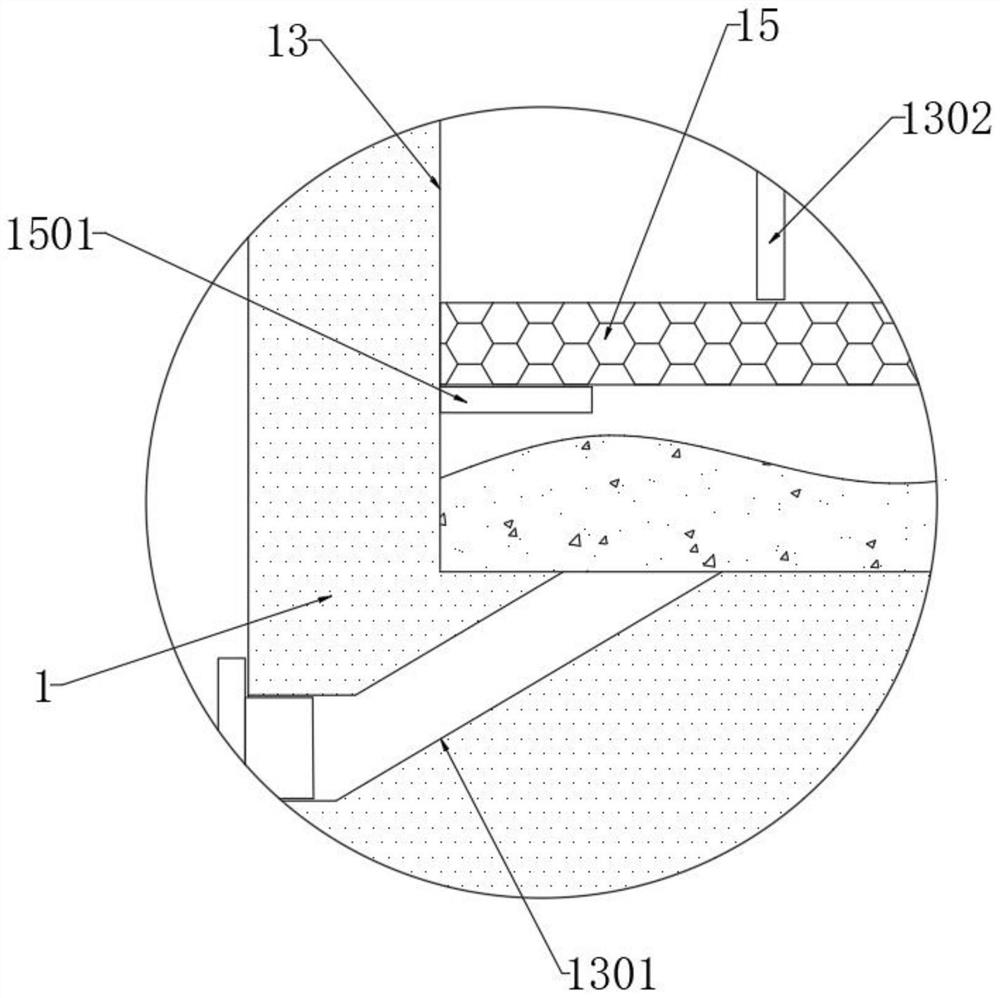

[0043] see Figure 1-7 , the grinding device in S2 includes a grinder main body 1, a plurality of brackets 2 are fixedly connected to the lower end of the grinder main body 1, a grinding tank 3 is dug in the grinder main body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com