Diaphragm containing mixed conductor coating and preparation method and application thereof

A hybrid conductor and coating technology, applied in the field of materials, can solve the problems of insignificant improvement in the heat resistance of the separator, poor battery cycle performance, poor wettability and ionic conductivity, etc., to improve the interface compatibility and improve the cycle. Performance and safety performance, moisture reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

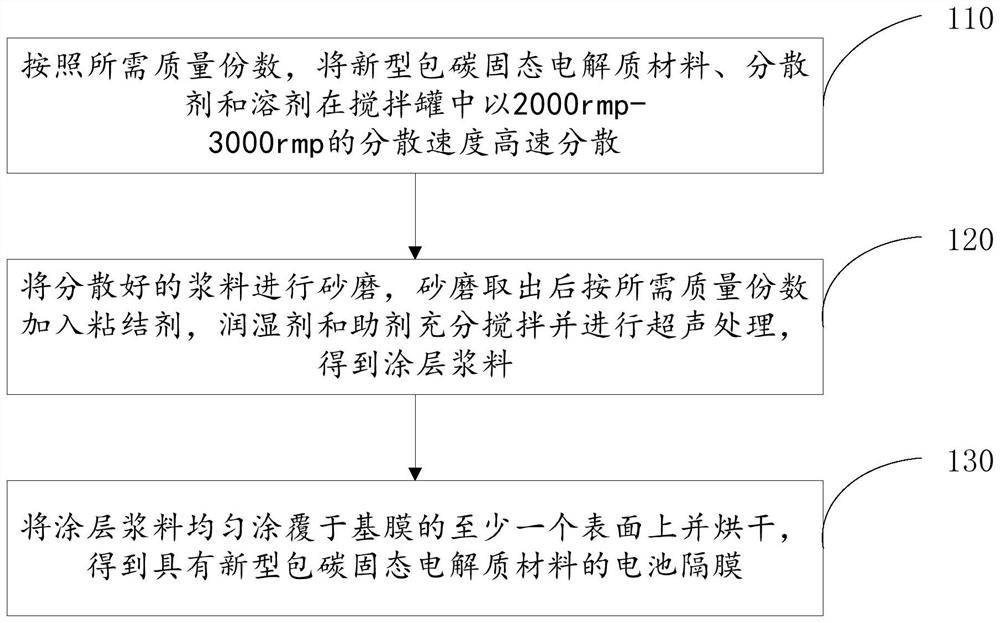

[0053] The above separator containing the mixed conductor coating can be obtained by the following preparation method. The specific method steps are as figure 1 shown, including:

[0054] Step 110, according to the required mass parts, the new carbon-coated solid electrolyte material, dispersant and solvent are dispersed at a high speed in a stirring tank at a dispersion speed of 2000rmp-3000rmp;

[0055] Step 120, sanding the dispersed slurry, taking it out after sanding, adding binder, wetting agent and auxiliary agent according to the required mass fraction, fully stirring and ultrasonic treatment, to obtain coating slurry;

[0056] In step 130, the coating slurry is evenly coated on at least one surface of the base membrane and dried to obtain a separator with a novel carbon-coated solid electrolyte material coating.

[0057] Specifically, the coating method includes any one of a doctor blade coating method, a gravure roll coating method, and a spray coating method.

[...

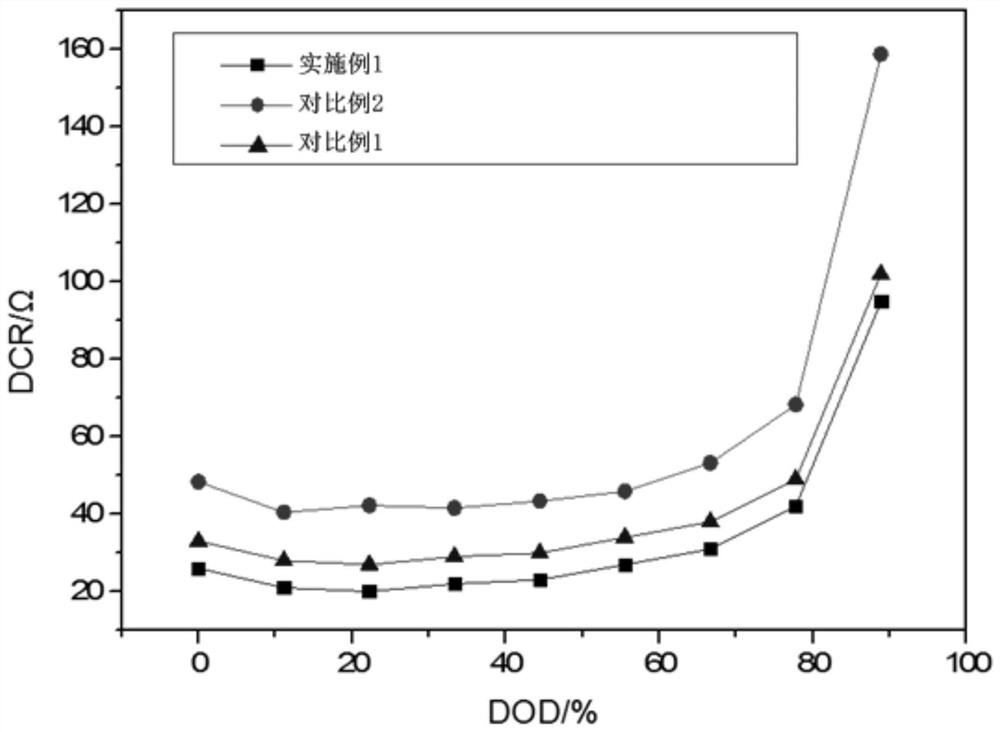

Embodiment 1

[0062] This embodiment provides a method for preparing a diaphragm with a mixed conductor coating.

[0063] Add 40g of polyethylene glycol, 20g of sodium carboxymethylcellulose and 8kg of deionized water into the pre-stirring tank, and disperse at a dispersion speed of 3000rpm for 1 hour to obtain the first slurry.

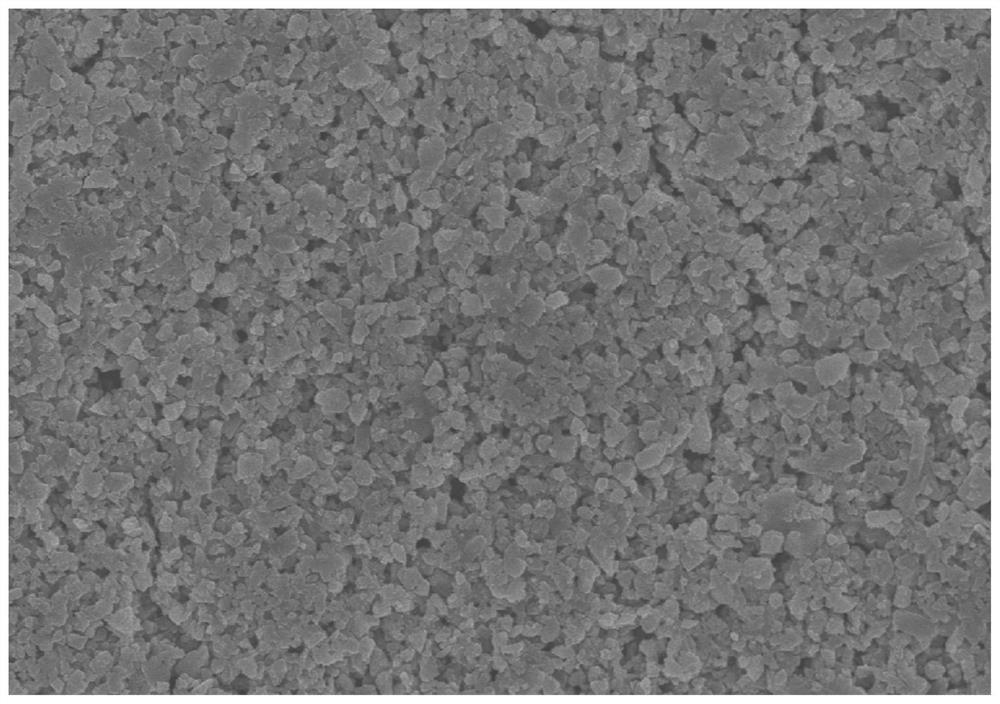

[0064] 1800g of the new carbon-coated solid electrolyte material Li 2 al 0.5 Zr 1.5 Si 0.5 P 2.5 o 12 / C-C (the ratio is 1:0.55:0.05) is added to the first slurry, dispersed at a dispersion speed of 2500rpm for 1.5 hours, and the dispersed slurry is put into a sand mill for sand grinding, and the sand grinding time is 0.5 hours to obtain the second Two slurry.

[0065] 200 g of styrene-butadiene rubber and 20 g of polyether-modified siloxane were added to the second slurry for thorough stirring to obtain a third slurry; wherein, the stirring speed was 30 rpm.

[0066] Ultrasonic treatment was performed on the third slurry for 0.5 hour at an ultrasonic frequ...

Embodiment 2

[0072] This embodiment provides a method for preparing a diaphragm with a mixed conductor coating.

[0073] 1900g of the new carbon-coated solid electrolyte material Li 2 Ga 0.5 Zr 1.5 Si 0.5 P 2.5 o 12 / C-C (ratio 1:0.4:0.03), 20g of sodium dodecylbenzenesulfonate, 20g of sodium hexametaphosphate, 200g of polyvinyl alcohol, 20g of polydimethylsiloxane and 8kg of deionized water Add it into a stirring tank, disperse and stir for 3 hours at 2500rmp.

[0074] Sand the dispersed slurry first, take it out, and then perform ultrasonic treatment. The process parameters are the same as in Example 1, and a slurry with a new carbon-coated solid electrolyte material is obtained.

[0075] The above-mentioned slurry with the new carbon-coated solid electrolyte material was uniformly coated on the inner and outer surfaces of the 9 μm polyethylene microporous membrane with an anilox roll and dried to obtain a double-sided coating with the new carbon-coated solid electrolyte material c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com