Implementation method of pelletizing water system communicating device

An implementation method and a technology for dicing water, which are applied in the field of polyamide polymerization processing, can solve problems such as delaying production, and achieve the effects of improving the quality of slices, avoiding clogging, and saving manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

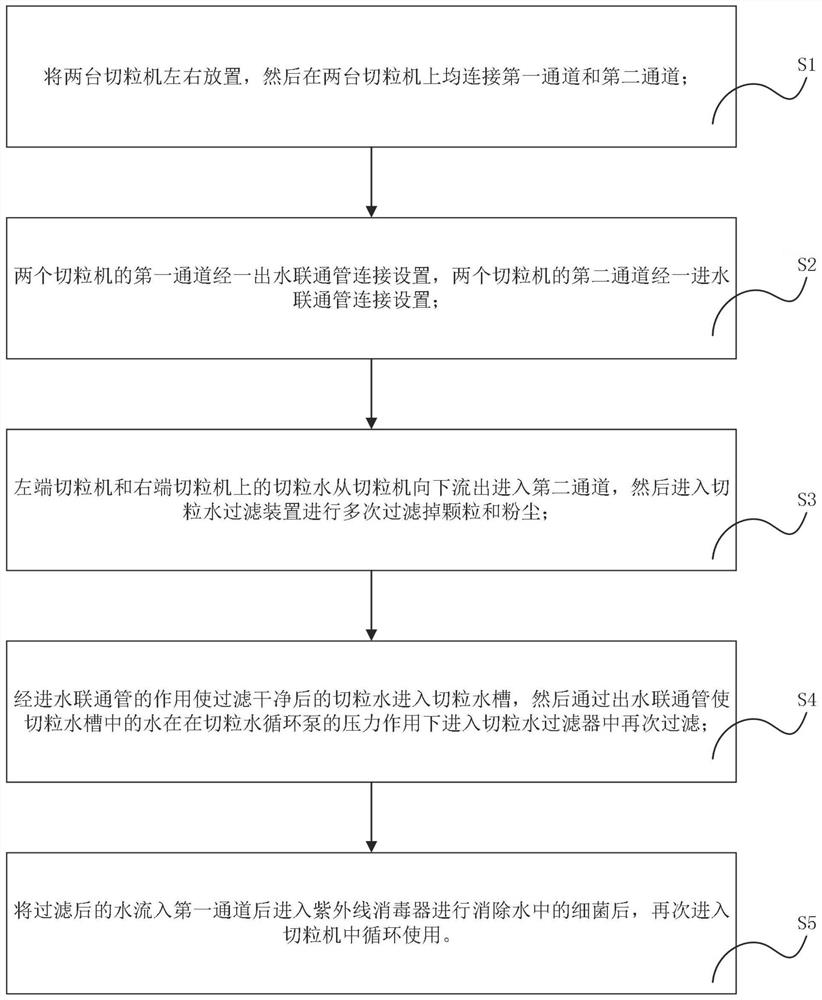

[0020] see figure 1 As shown, a method for realizing a cutting water system communication device in the present invention comprises the following steps:

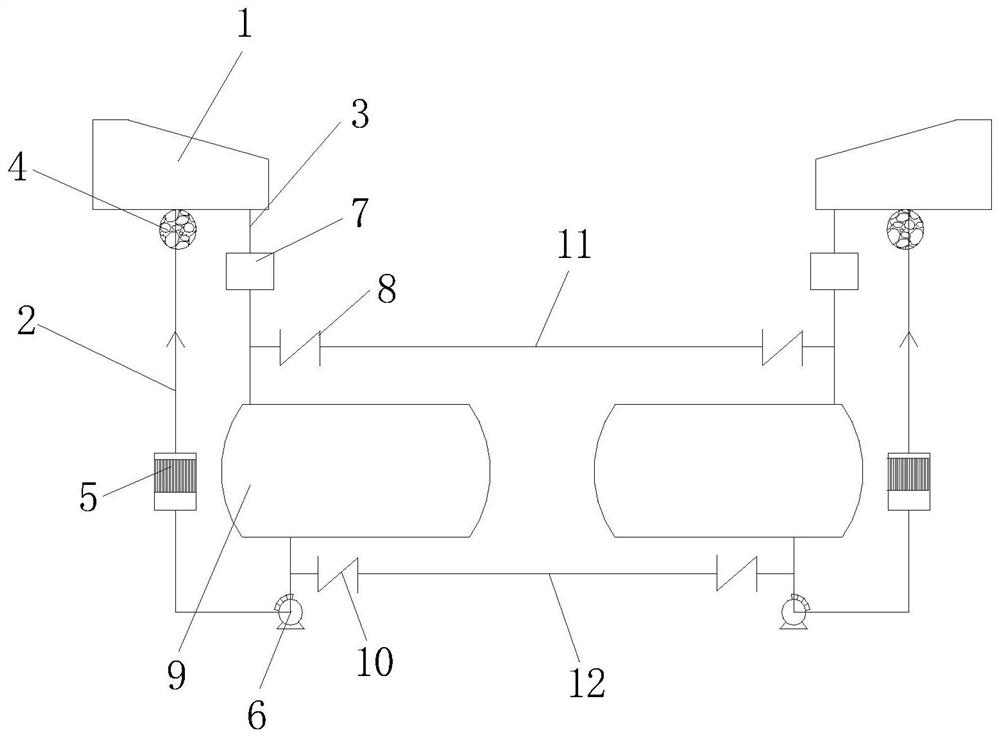

[0021] Step S1, place the two pelletizers 1 left and right, and then connect the first channel 2 and the second channel 3 on the two pelletizers 1;

[0022] Step S2, the first channels 2 of the two pelletizers 1 are connected and set through a water outlet communication pipe 12, and the second channels of the two pelletizers 1 are connected and set through a water inlet communication pipe 11;

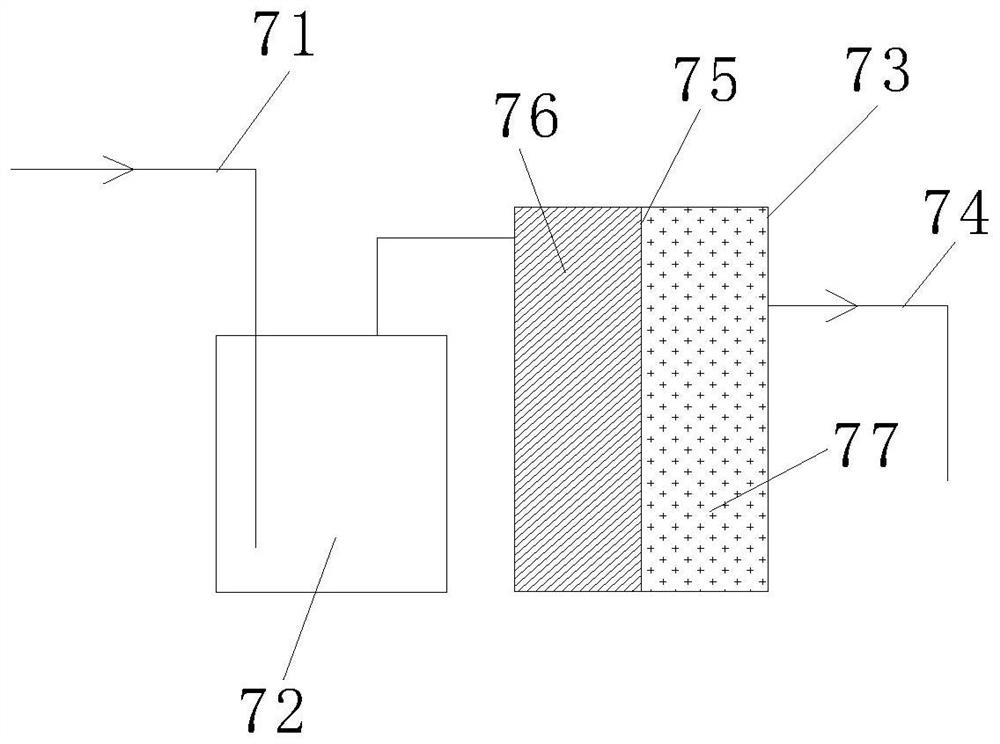

[0023] Step S3, the granulation water on the left end granulator 1 and the right end granulator flows downward from the granulator 1 into the second channel 3, and then enters the granulation water filter device 7 to filter out particles and dust for many times;

[0024] Step S4, through the function of the water inlet commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com