Laser-induced transfer micro electronic component printing method based on non-Newtonian fluid characteristics

A non-Newtonian fluid, laser-induced technology, applied in the direction of process efficiency improvement, energy efficiency improvement, additive manufacturing, etc., can solve the problems of large structure size of deposited material, nozzle blockage, and low accuracy of deposited material delivery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

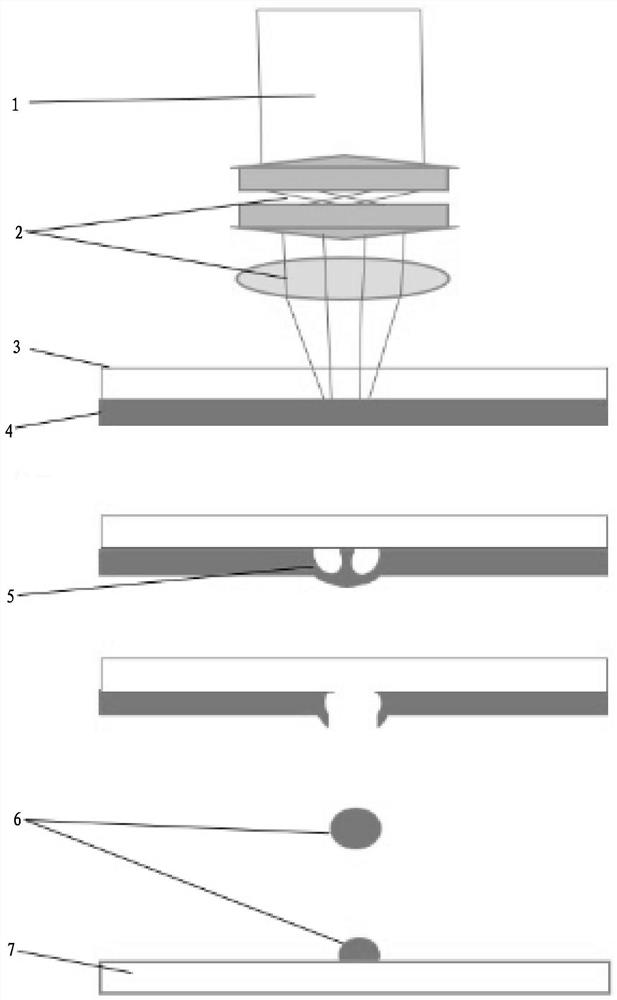

[0025] see figure 1 and figure 2 , this embodiment relates to a laser-induced transfer microelectronic component printing method based on non-Newtonian fluid characteristics, comprising the following steps:

[0026] Include the following steps:

[0027] Step 1. The pulsed laser beam 1 is incident on the combination lens, and the ring beam is formed after being shaped by the combination lens 2; the ring beam passes through the transparent cover plate 3 and focuses on the non-Newtonian fluid doped metal nanoparticle solution 4 to form a ring spot; During the process, the size of the inner and outer diameters of the annular light spot can be changed by adjusting the relative position between the lens of the combination lens 2 and the transparent cover plate 3;

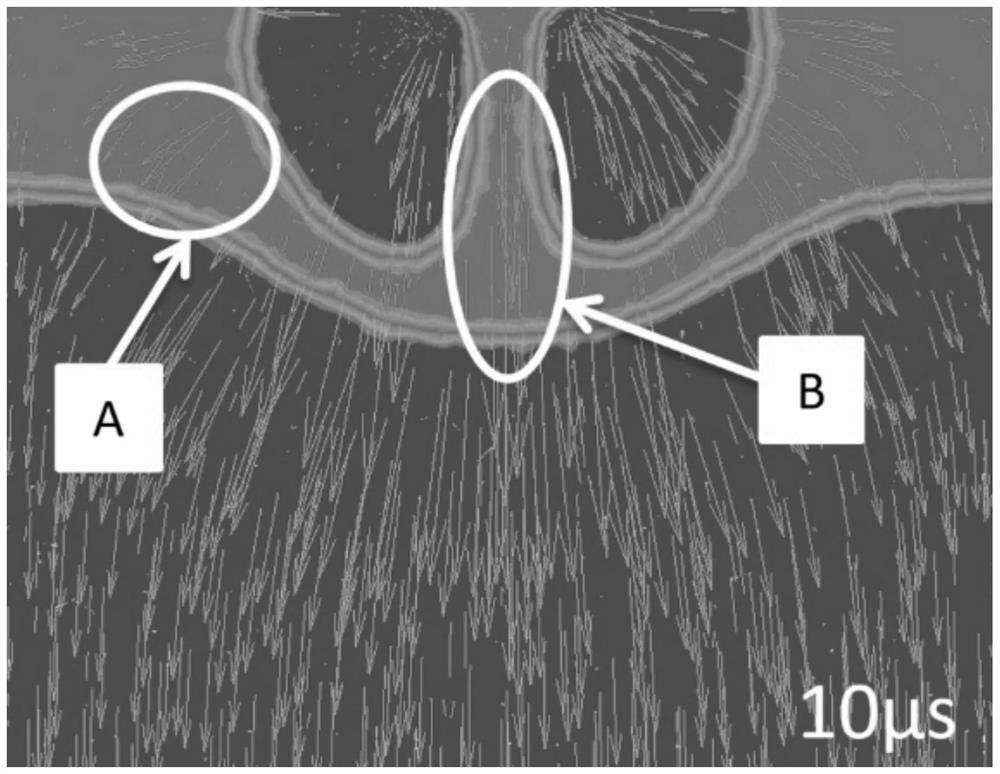

[0028] Step 2, the nano-metal particles are ablated under the light and heat of the laser and form a plasma annular cavitation bubble 5;

[0029] Step 3, the ring-shaped cavitation bubble 5 rapidly expands and pushes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com