Antioxidant, preparation method and application thereof

An antioxidant and reaction technology, applied in chemical instruments and methods, organic chemistry, compounds of Group 5/15 elements of the periodic table, etc., can solve the complex synthesis process, phosphorus trichloride corrosion, toluene solvent is not environmentally friendly, etc. problem, to achieve the effect of simple preparation method, improved mechanical strength, high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The second aspect of the present invention provides a kind of preparation method of said antioxidant, comprising: triethyl phosphite, tetrahydric alcohol, C n h 2n+2 The alcohol represented by O and the catalyst are put into the reactor and reacted at 120-165°C for 4-6h to obtain the product.

[0045] In one embodiment, the preparation method of the antioxidant comprises: triethyl phosphite, tetrahydric alcohol, C n h 2n+2 Put the alcohol represented by O and the catalyst into the reactor, and react at 165°C for 4-6h to obtain it.

[0046] In one embodiment, the preparation method of the antioxidant comprises: triethyl phosphite, tetrahydric alcohol, C n h 2n+ 2 The alcohol represented by O and the catalyst are put into the reaction kettle, and reacted at 130-165°C for 4-6h under double-speed and helical propulsion stirring to obtain the product.

[0047] The applicant found in the experiment that when the reaction temperature exceeded 130°C (including 130°C), the...

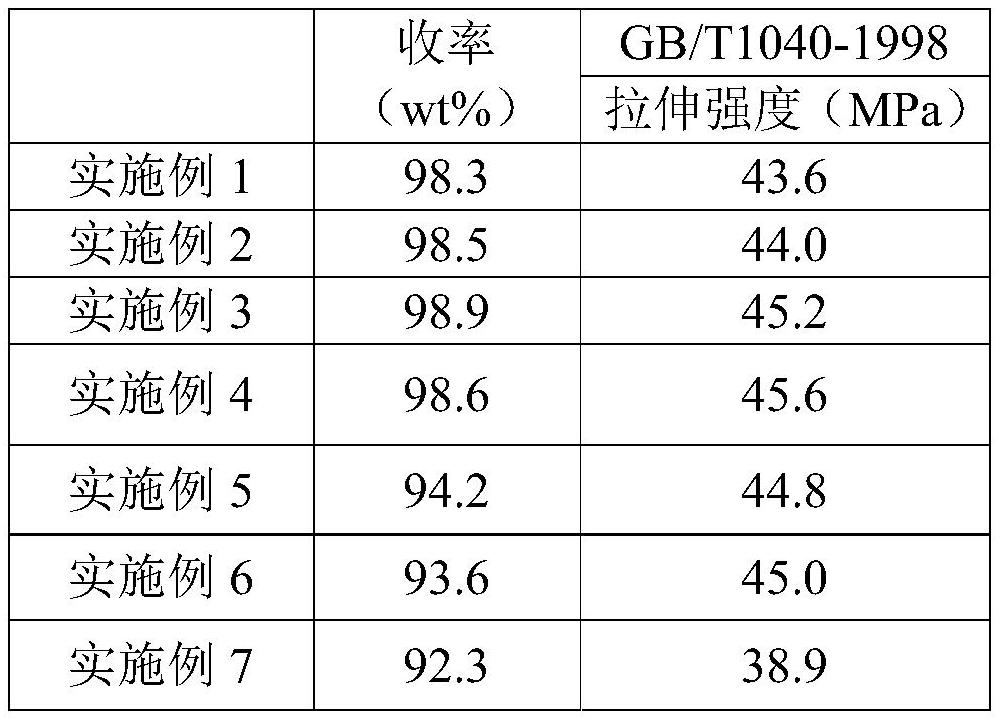

Embodiment 1

[0055] Embodiment 1 of the present invention provides a kind of antioxidant, its preparation raw material comprises triethyl phosphite, pentaerythritol, n-octanol, n-decyl alcohol, n-tridecanol, catalyst.

[0056] The catalyst is lithium hydroxide and sodium hydroxide with a weight ratio of 1:1.

[0057] The catalyst is 3 wt% of triethyl phosphate.

[0058] The molar ratio of n-octanol, n-decyl alcohol and n-tridecyl alcohol is 0.1:1:1.

[0059] The molar ratio of the triethyl phosphite, pentaerythritol and the total amount of n-octanol, n-decyl alcohol and n-tridecyl alcohol is 1:0.3:0.5.

[0060] The preparation method of the antioxidant is as follows: triethyl phosphite, pentaerythritol, n-octanol, n-decyl alcohol, n-tridecyl alcohol, and catalysts are put into the reaction kettle, and under double-speed and screw propulsion stirring, the React at 165°C for 4h, heat up to remove ethanol, and filter to obtain the product.

Embodiment 2

[0062] Embodiment 2 of the present invention provides a kind of antioxidant, its preparation raw material comprises triethyl phosphite, pentaerythritol, n-octanol, n-decyl alcohol, n-tridecanol, catalyst.

[0063] The catalyst is lithium hydroxide and sodium hydroxide with a weight ratio of 1:10.

[0064] The catalyst is 5 wt% of triethyl phosphate.

[0065] The molar ratio of n-octanol, n-decyl alcohol and n-tridecyl alcohol is 0.8:5:1.

[0066] The molar ratio of the triethyl phosphite, pentaerythritol and the total amount of n-octanol, n-decyl alcohol and n-tridecyl alcohol is 1:0.8:1.2.

[0067] The preparation method of the antioxidant is as follows: triethyl phosphite, pentaerythritol, n-octanol, n-decyl alcohol, n-tridecyl alcohol, and catalysts are put into the reaction kettle, and under double-speed and screw propulsion stirring, the React at 165°C for 6h, heat up to remove ethanol, and filter to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com