Microencapsulated royal jelly enzymolysis polypeptide, preparation method thereof and solid powder containing microencapsulated royal jelly enzymolysis polypeptide

A technology of microencapsulation and royal jelly, which is applied in the field of solid powder, its preparation, and microencapsulation of royal jelly enzymatic peptides, which can solve the problems of spoilage, limit the processing, storage and utilization of queen bee larvae, reduce hygroscopicity, and increase the use value , Improve the effect of biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

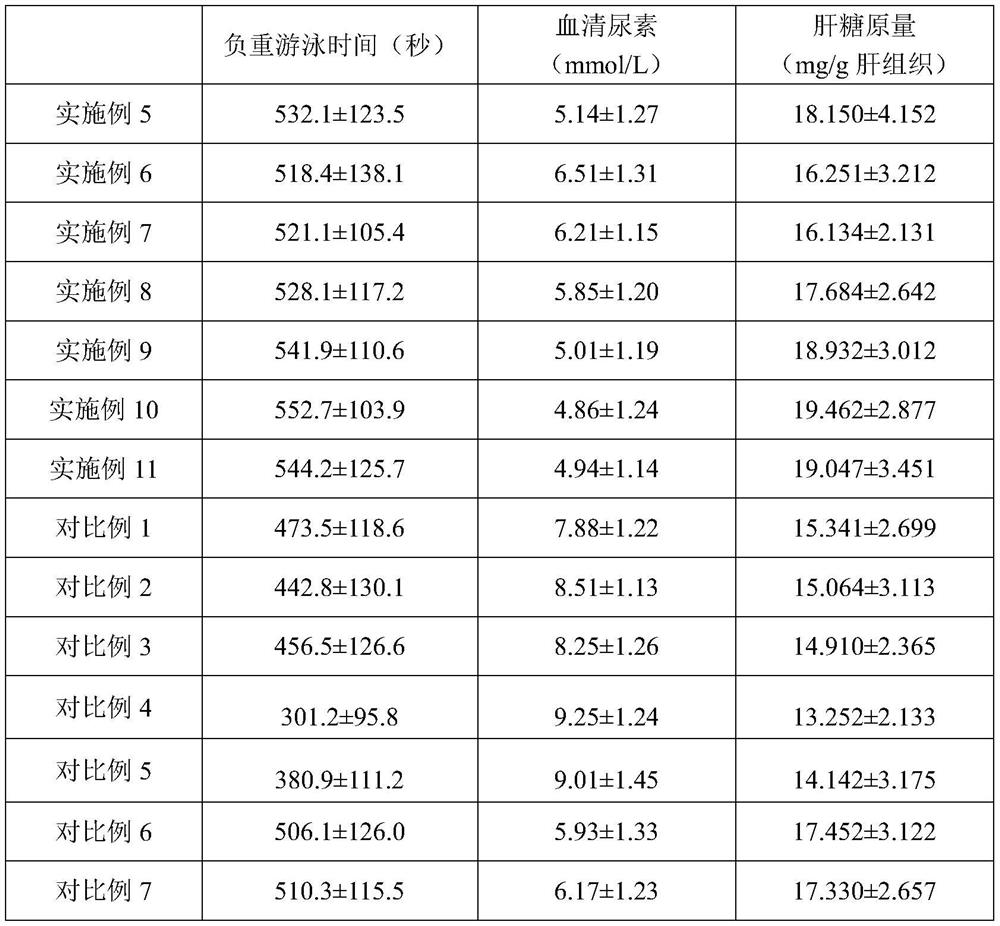

Examples

preparation example Construction

[0047] In a first aspect, the present application provides a method for preparing a microencapsulated royal jelly enzymatically hydrolyzed polypeptide, which comprises the following steps:

[0048] (1) mixing royal jelly with water, then centrifuging to get the supernatant;

[0049] (2) adding pepsin to the supernatant obtained in step (1) for enzymolysis to obtain a primary enzymolysis solution;

[0050] (3) Adding trypsin to the primary enzymolysis solution for enzymolysis to obtain a secondary enzymolysis solution;

[0051] (4) centrifuging the secondary enzymolysis solution, and taking the supernatant; and

[0052] (5) Add embedding wall material to the supernatant obtained in step (4), grind and homogenize, and obtain the microencapsulated royal jelly enzymatic polypeptide.

[0053] In this application, the protein in royal jelly is decomposed into small molecular peptides by proteolysis technology, so that the allergic problem of royal jelly can be well solved, and the...

Embodiment 1

[0086] Adopt the following preparation method of microencapsulated royal jelly enzymatic polypeptide according to the present application to prepare microencapsulated royal jelly enzymatic polypeptide:

[0087] (1) mixing royal jelly and water with a weight ratio of 1:0.8 under ultrasonic conditions, and then centrifuging to get the supernatant;

[0088] (2) adding pepsin to the supernatant obtained in step (1) at an enzyme-substrate concentration ratio of 0.3%, and enzymatically hydrolyzing for 50 minutes at a temperature of 45° C. to obtain a primary enzymolyzate;

[0089] (3) Using a sodium hydroxide solution with a mass concentration of 5% to adjust the pH of the primary enzymolysis solution to 8, add trypsin at a temperature of 40° C. at a concentration ratio of 0.7% to the enzyme substrate, and perform enzymolysis for 40 minutes. Obtain the secondary enzymatic hydrolysis solution;

[0090] (4) centrifuging the secondary enzymolysis solution, and taking the supernatant; ...

Embodiment 2

[0093] Adopt the following preparation method of microencapsulated royal jelly enzymatic polypeptide according to the present application to prepare microencapsulated royal jelly enzymatic polypeptide:

[0094] (1) mixing royal jelly and water with a weight ratio of 1:1 under ultrasonic conditions, and then centrifuging to get the supernatant;

[0095] (2) adding pepsin to the supernatant obtained in step (1) at an enzyme-substrate concentration ratio of 0.4%, and enzymatically hydrolyzing for 40 minutes at a temperature of 40° C. to obtain a primary enzymolyzate;

[0096] (3) Using a sodium hydroxide solution with a mass concentration of 8% to adjust the pH of the primary enzymolysis solution to 8, add trypsin at a temperature of 45° C. at a concentration ratio of 0.6% to the enzyme substrate, and perform enzymolysis for 60 minutes. Obtain the secondary enzymatic hydrolysis solution;

[0097] (4) centrifuging the secondary enzymolysis solution, and taking the supernatant;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com