Self-heating wet tissue and application method thereof

A self-heating, wet wipe technology, applied in chemical instruments and methods, household appliances, food heating containers, etc., can solve problems such as inconvenience to use, wet wipes have no self-heating function, etc., and achieve the effect of safe use and no skin irritation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

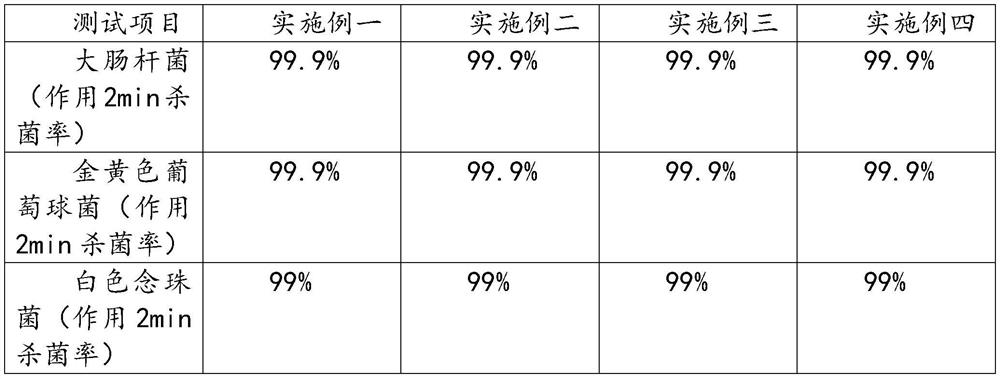

Embodiment 1

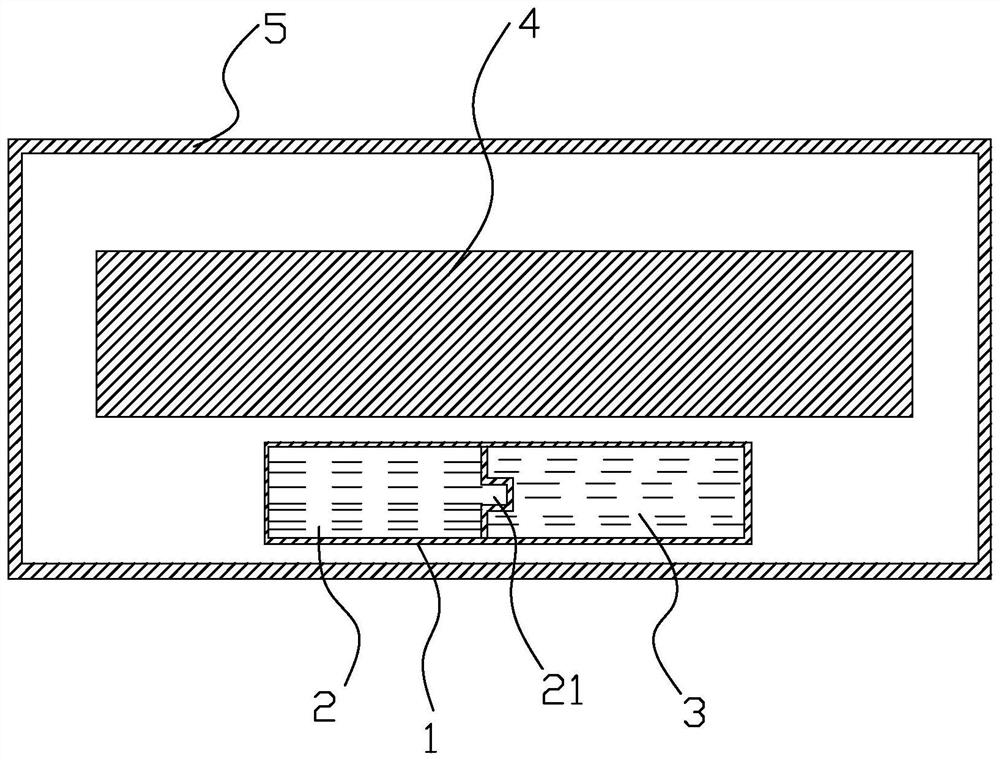

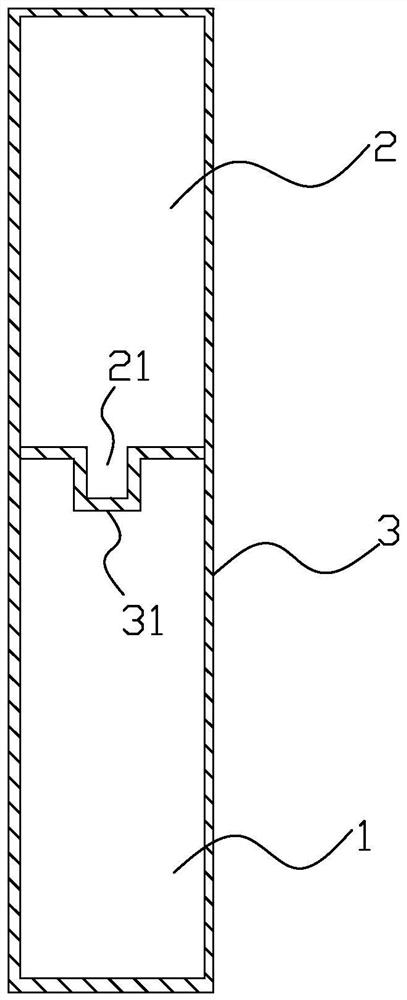

[0027] refer to figure 1 and figure 2 , a self-heating wet tissue, comprising an outer packaging bag, the outer packaging bag is equipped with a non-woven fabric made of viscose fiber and wood pulp fiber, and also includes an independently packaged self-heating liquid, the self-heating The liquid consists of a water system and a polyol system, the water system and the polyol system are independently contained in two closed cavities, and the two closed cavities communicate with each other through extrusion. Specifically, this The water system of the embodiment is deionized water, and the polyol system is: 50 parts by weight of propylene glycol, 5 parts of methylparaben, 5 parts of chlorphenidin, 5 parts of p-hydroxyacetophenone, 3 parts of benzalkonium chloride, A mixture of 17 parts of cetrimonium bromide and 15 parts of ethylhexylglycerin. More specifically, the self-heating wet tissue of the present embodiment is a wet tissue packaged in a single piece, that is, a piece of...

Embodiment 2

[0031] Referring to Example 1, the polyol system of this Example 1 is a single propylene glycol, and the water system is deionized water, that is, the self-heating liquid applied to a piece of spunlace nonwoven fabric is composed of deionized hydration propylene glycol. Similarly, These two components are packed in two independent closed film bags, each piece of non-woven fabric is about 2g, the amount of deionized water is 4g, and the amount of propylene glycol is 4g.

Embodiment 3

[0033] Referring to Example 1, the difference from Example 1 is that the polyol system of this example is: 50 parts by weight of glycerol, 8 parts of methyl paraben, 5 parts of chlorphenidin, 7 parts of p-hydroxyacetophenone 5 parts, 5 parts of benzalkonium chloride, 10 parts of cetrimonium bromide, and 15 parts of ethylhexylglycerin. More specifically, the self-heating wet wipes of this embodiment are wet wipes packaged in single sheets, that is, one There is a piece of folded non-woven fabric inside the plastic sealing pouch, and there is also a film bag with two independent closed cavities inside the pouch, and the two cavities of the film bag are filled with deionized water and polyol system respectively , the specification of the non-woven fabric is 170*180mm, and the basis weight of the non-woven fabric is 60g / m 2 , that is, each piece of non-woven fabric is about 2g, the amount of deionized water is 4g, the total amount of polyol system is 2g, and the amount of each com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Base weigh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com