Ultra-magnetostrictive soic wave transmitting energy converter

A technology of giant magnetostriction and acoustic wave emission, which is applied in the direction of magnetostrictive sensors, instruments, sensors, etc., can solve the problems of large randomness, large volume, and narrow bandwidth, and achieve long penetration distance, good repeatability, and wide bandwidth. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

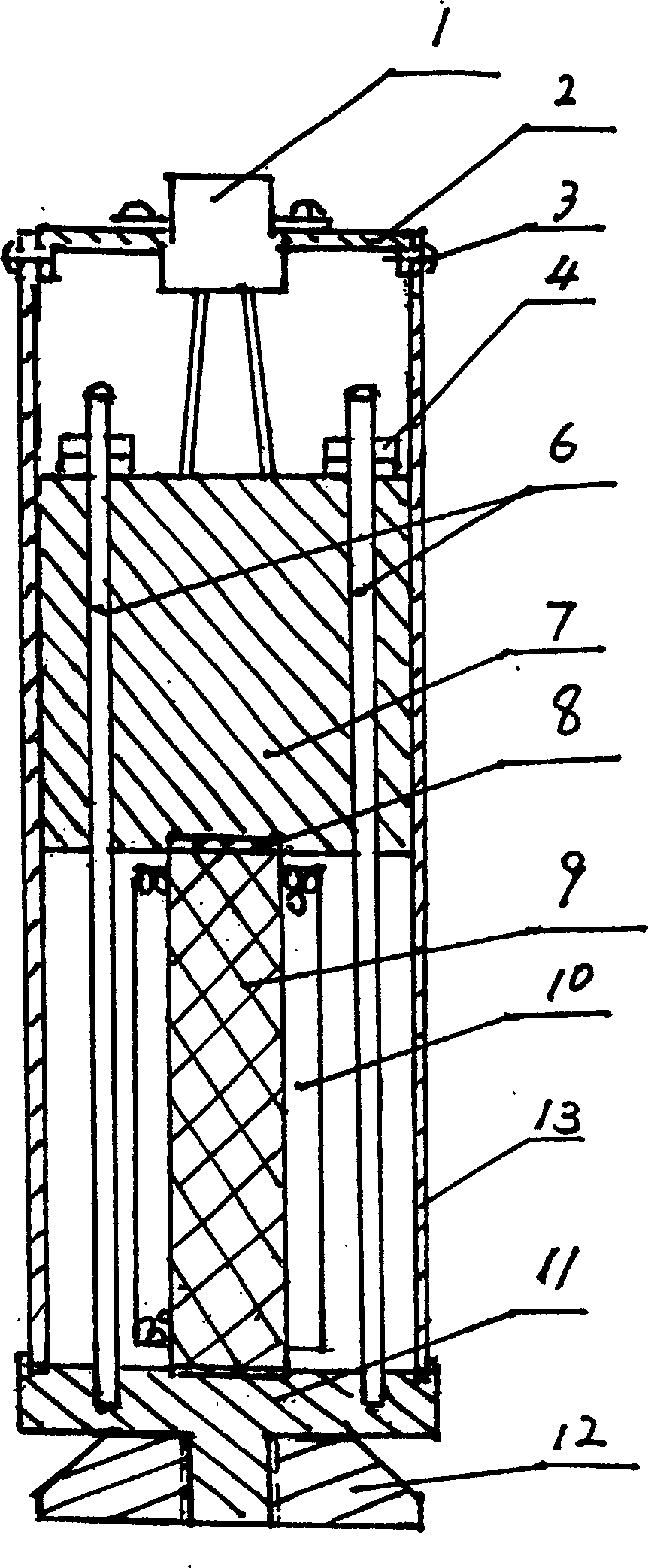

[0022] Embodiment 1: (as figure 1 shown)

[0023] In the super magnetostrictive ground acoustic wave transmitting transducer described in the present embodiment, it consists of plug base (1), pull rod (6), briquetting block (7), super magnetic rod (9), coil (10), cover plate , a radiation block (12), and a casing (13), the supermagnetic bar (9) coated with protective paint is wound with a coil (10), placed in the casing (13), front and rear cover plates (11), (2); the upper and lower ends of the supermagnetic bar (9) are connected with the briquetting block (7) and the front cover (11) respectively, and gaskets (8) are lined in the middle; one end of the pull rod (6) is connected with the front cover (11) Fixed connection, the other end passes through the pressing block (7), fixed with the nut (4), the radiation block (12) is threadedly connected with the front cover (11), and the lead wires at both ends of the coil (10) are connected to the plug seat (1) links to each other...

Embodiment 2

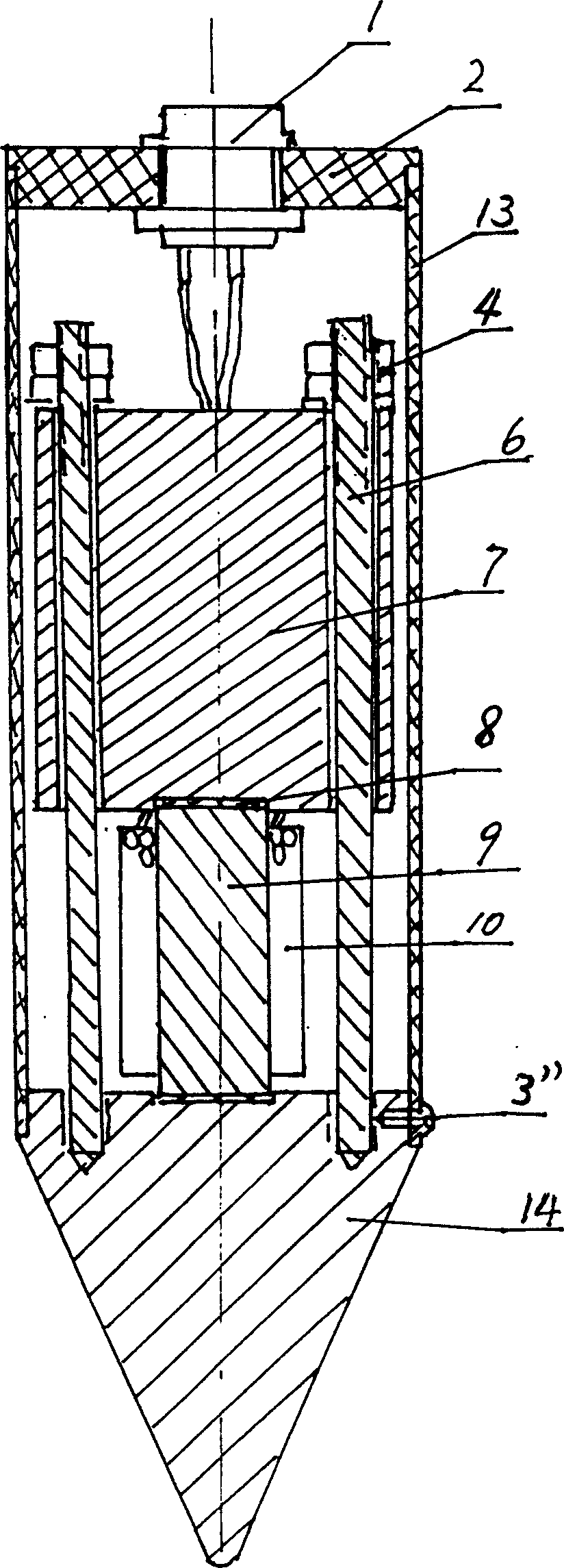

[0027] Embodiment 2: (as figure 2 shown)

[0028]In the acoustic wave emitting transducer for the super-magnetic telescopic ground anchor described in the present embodiment, it consists of plug base (1), pull rod (6), briquetting block (7), super-magnetic rod (9), coil (10), Cover plate, radiating head (14), casing (13) are made up of, and coil (10) is wound on the supermagnetic bar (9) that is coated with protective paint, is placed in the casing (13), and radiating head (14) and Between the rear cover plates (2); the upper and lower ends of the supermagnetic bar (9) are connected with the briquetting block (7) and the radiation head (14) respectively, and gaskets (8) are lined in the middle, and one end of the pull rod (6) is connected with the The radiation head (14) is fixedly connected, and the other end passes through the pressing block (7), and is fixed with a nut (4). On the back cover (2), the two ends of the shell (13) are respectively connected with the radiatio...

Embodiment 3

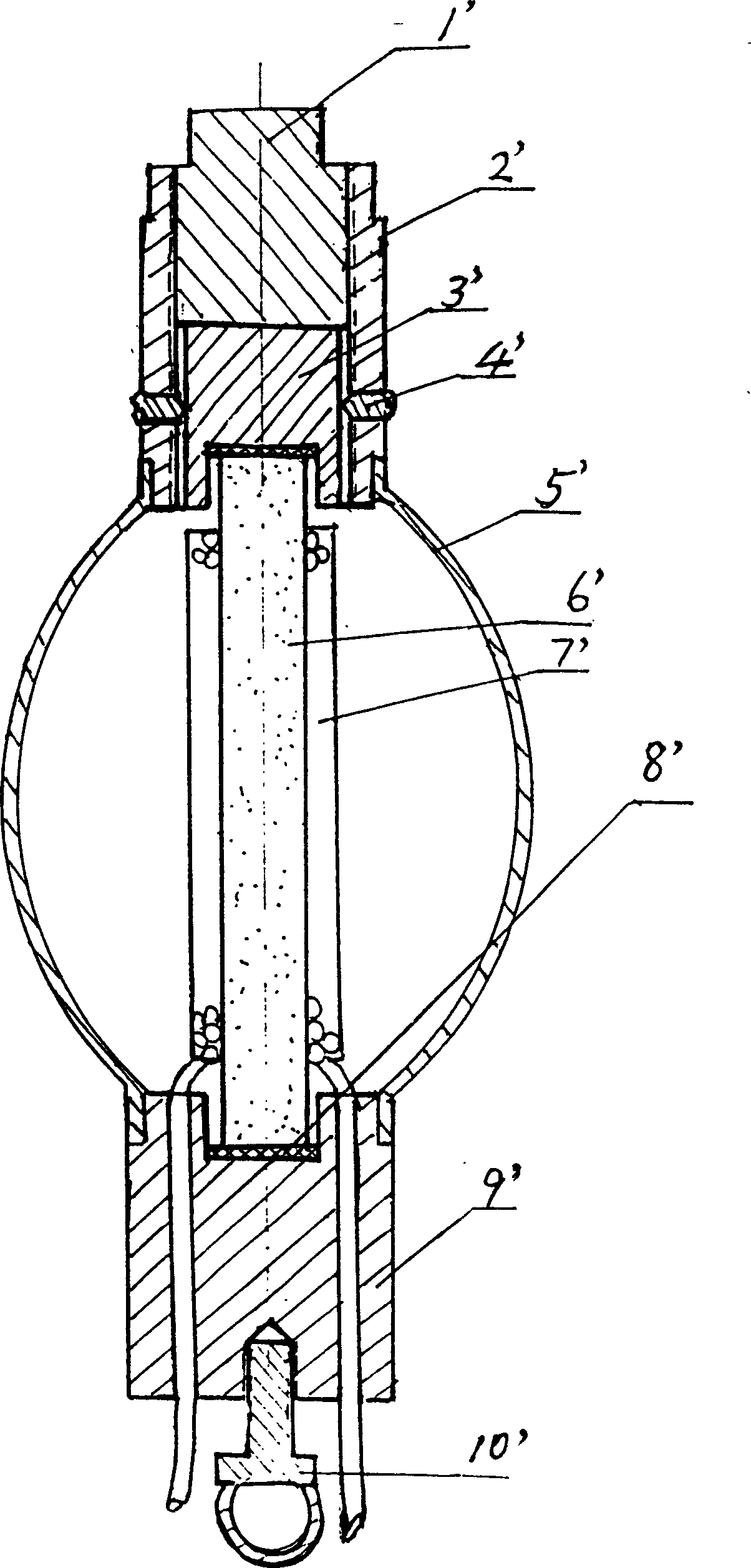

[0032] Embodiment 3: (as image 3 shown)

[0033] In the acoustic wave transmitting transducer in the super-magnetic telescopic well described in the present embodiment, it consists of a rotary block (1'), a briquetting block (3'), an amplitude bar (5'), a super-magnetic bar (6'), a coil ( 7'), upper and lower cover plates (2'), (9') and suspension rings (10'), and a coil (7') is wound on the supermagnetic strip (6'), and its upper and lower ends are respectively connected with the pressing block (3') is connected with the lower cover plate (9'), and is lined with a backing plate (8') in the middle; there are 8 amplitude bars (5'), which are curved and arranged at equal intervals along the circumference. They are fixedly connected with the upper and lower cover plates (2') and (9') respectively to form a lantern-shaped curved shell and radiating surface, which converts the vertical vibration into the radial vibration of the lantern wall and makes the sound waves radiate in ei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com