Manufacturing method of semiconductor device and PIN photodiode

A manufacturing method and semiconductor technology, applied in the direction of semiconductor devices, circuits, electrical components, etc., can solve the problems of high cost, dielectric film separation, large stress, etc., and achieve the effect of improving device performance, reducing manufacturing costs, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

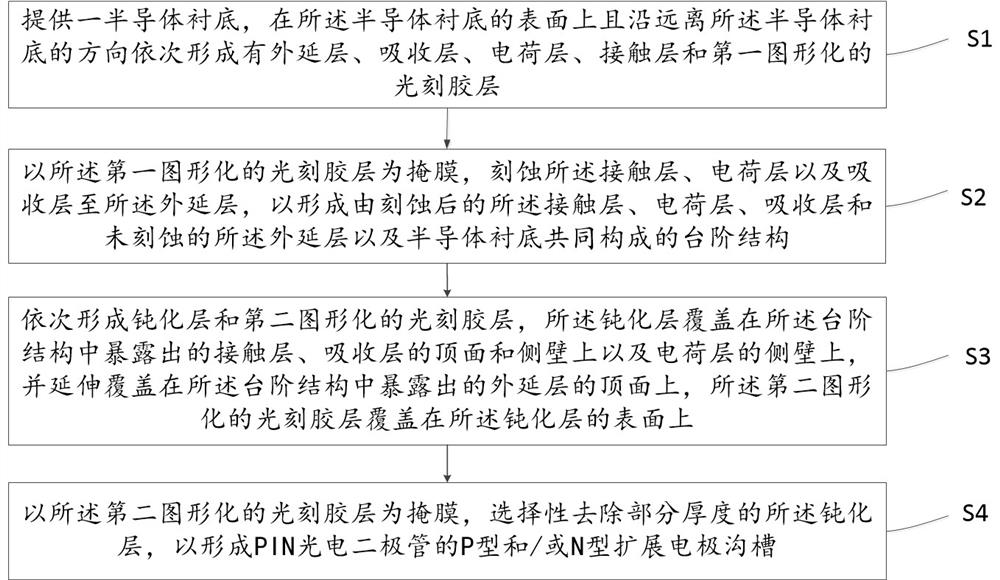

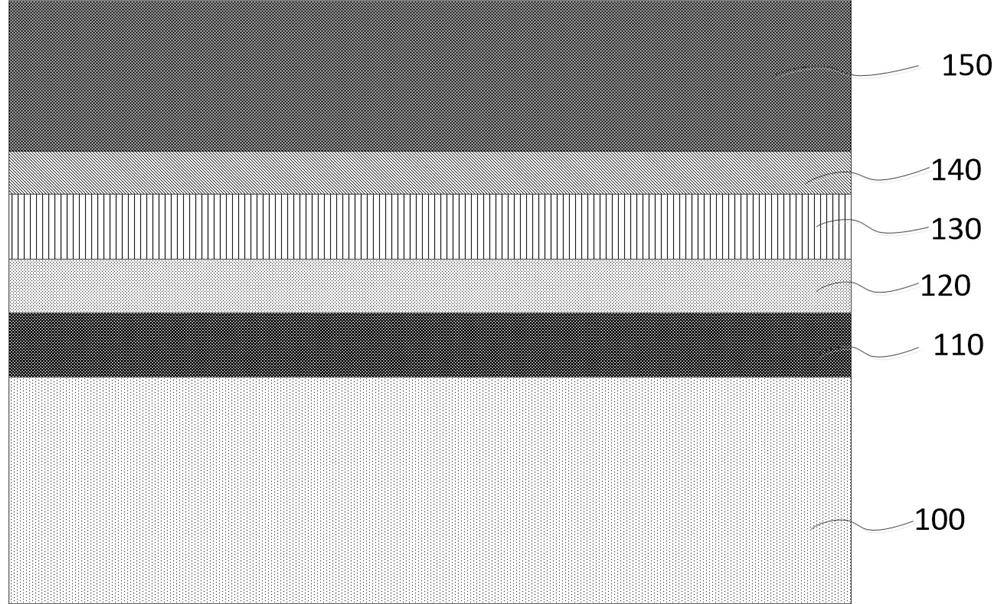

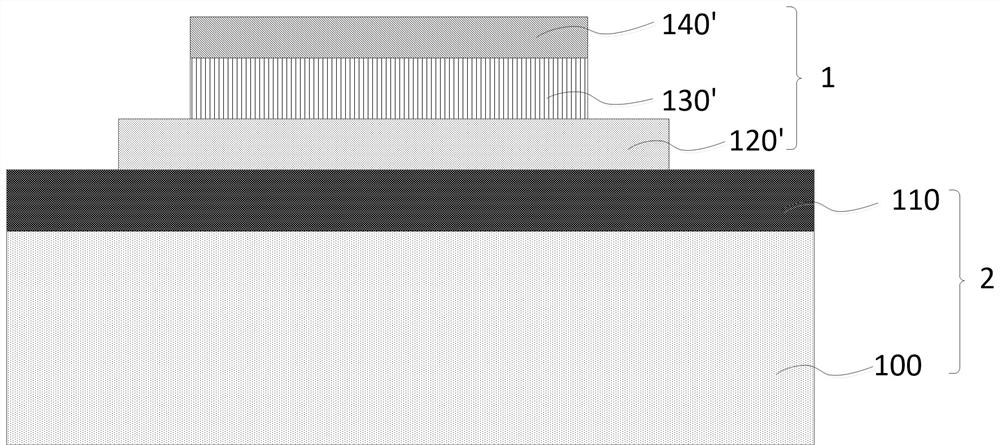

[0040]As mentioned in the background technology, at present, for high-speed PIN photodetectors, one step in the existing device manufacturing process is the passivation process of the device. For example, the existing manufacturing processes such as 10G PIN, 25G PIN, and 36G PIN are all The organic passivation film BCB (benzocyclobutene BCB) is used to replace the chemical vapor deposition passivation process to reduce the stress of the device, thereby reducing the junction capacitance, but due to the high cost of the organic passivation film BCB, and the main material of the material The source depends on imports, which leads to the high cost of manufacturing photodetector devices; for this problem, if passivation is carried out with lower cost inorganic passivation films (Si3N4 and SiO2), although it can reduce the cost of manufacturing photodetector devices. cost, but the inorganic passivation film material will introduce a large stress, and it is easy to cause part of the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com