Hydrogen storage alloy, negative electrode containing hydrogen storage alloy, and nickel-hydrogen secondary battery containing negative electrode

A hydrogen storage alloy, secondary battery technology, applied in secondary batteries, nickel storage batteries, negative electrodes, etc., can solve problems such as the reduction of cycle life characteristics, achieve low temperature discharge characteristics and cycle life characteristics improvement, and realize low temperature discharge characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

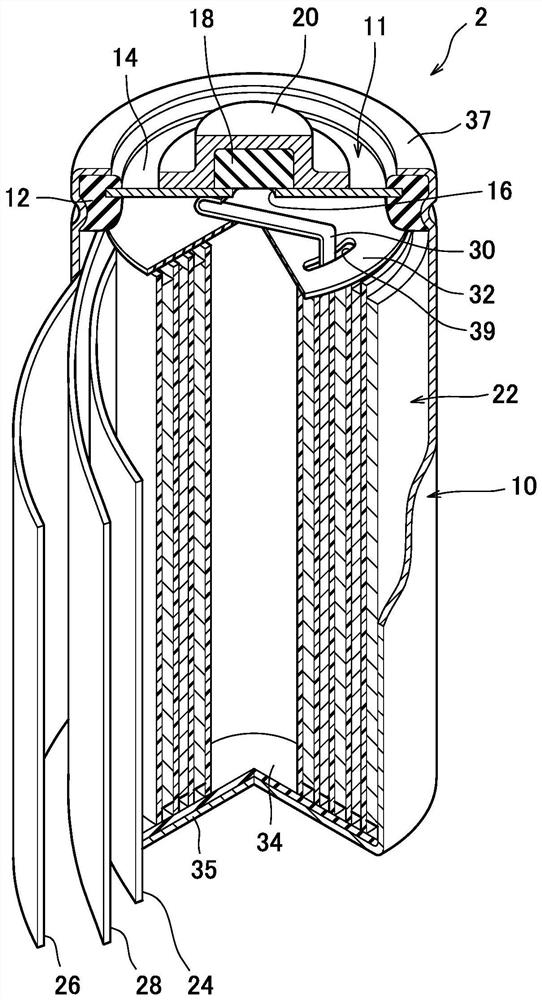

Image

Examples

Embodiment 1

[0050] (1) Production of hydrogen storage alloy and negative electrode

[0051] First, La, Mg, Ni, and Al were weighed and mixed to obtain a mixture having a molar ratio of 0.763:0.237:3.30:0.10. The resulting mixture was melted in an induction melting furnace, and the melt was poured into a mold, and then cooled to room temperature (25° C.) to obtain an ingot of a hydrogen storage alloy. The composition of the sample collected from this ingot was analyzed by high-frequency inductively coupled plasma spectrometry (ICP). As a result, the composition of the hydrogen storage alloy is La 0.763 Mg 0.237 Ni 3.30 al 0.10 .

[0052] Next, the obtained ingot was filled in a container, and the inside of the container was replaced with argon gas, and then the container was sealed. This container was put into a heat treatment furnace, and it held at the temperature of 1000 degreeC for 10 hours, and the ingot was heat-processed under an argon atmosphere. Then, after the heat treatme...

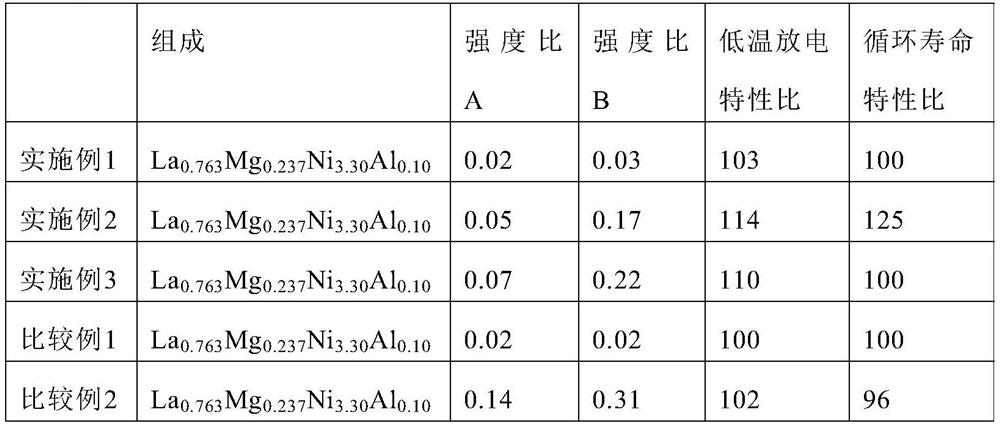

Embodiment 2~3、 comparative example 1~2

[0067] A nickel-hydrogen secondary battery was obtained in the same manner as in Example 1, except that the heat treatment temperature of the hydrogen storage alloy was changed so that the strength ratio A and the strength ratio B reached the values shown in Table 1.

[0068] 2. Evaluation of Ni-MH secondary battery

[0069] (1) Low temperature discharge characteristics

[0070] For the batteries prepared in Examples 1-3 and Comparative Examples 1-2, a charging current of 2.3A was flowed in an environment of 25°C. After the battery voltage reached the maximum value, the battery was charged so that the voltage dropped to 10mV, and then rested for 1 hour. . Then, the battery after resting for 1 hour was discharged at a discharge current of 2.3 A in an environment of 25° C. until the battery voltage reached 1.0 V. At this time, the discharge capacity was measured, and this discharge capacity was regarded as the initial capacity of the battery.

[0071] For the batteries of E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com