Shampoo

A technology of shampoo and composition, applied in the field of shampoo, can solve the problems of oily scalp, destroying bacteria flora, etc., and achieve the effect of improving anti-dandruff, anti-itching, avoiding static electricity, and avoiding dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

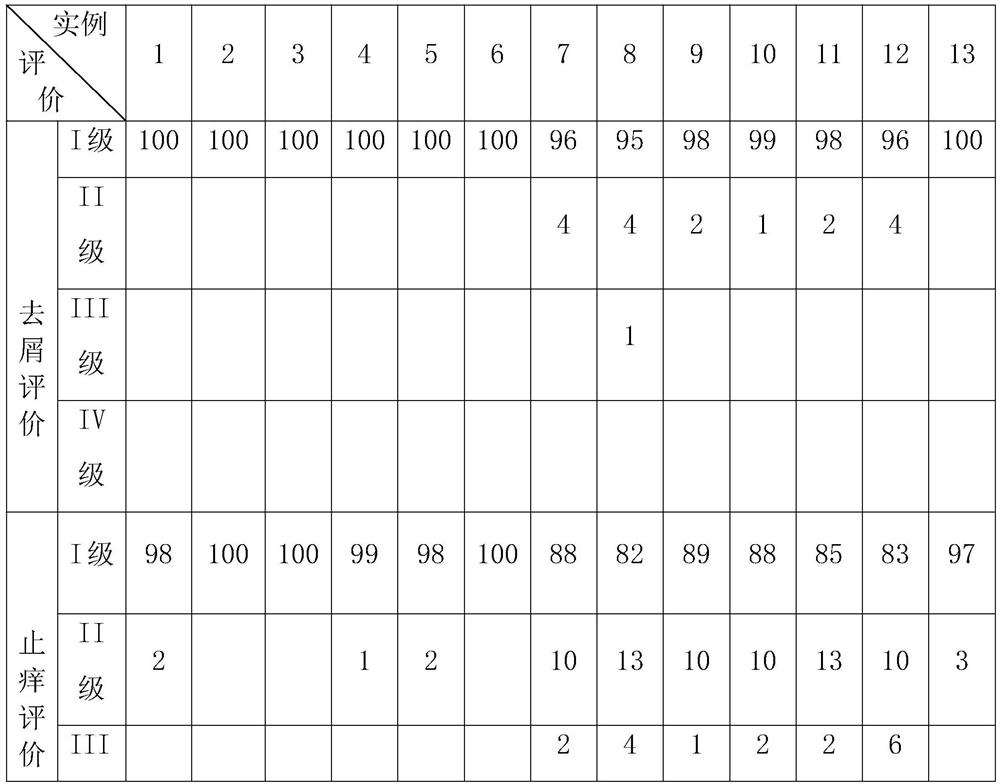

Examples

Embodiment 1

[0039] Specifically, the raw materials by weight are as follows:

[0040] The first component phase: 400 parts of water, 2 parts of guar gum hydroxypropyl trimethyl ammonium chloride, 2 parts of behenyloxy PG-trimethyl ammonium chloride, 10 parts of glycerin;

[0041] The second component phase: 120 parts of sodium laureth sulfate (ammonium), 10 parts of sodium lauryl sulfate (ammonium), 20 parts of disodium laureth sulfosuccinate;

[0042] The third component phase: 5 parts of cocamide MEA, 50 parts of cocamidopropyl betaine, 10 parts of acrylic acid (ester) / C10-30 alkanol acrylate crosslinked polymer;

[0043] The fourth component phase: 1 part of titanium dioxide, 30 parts of silicone oil, 60 parts of polyquaternium-30;

[0044] Composition of the fifth component: 30 parts of Zanthoxylum bungeanum extract, 2 parts of preservative, 5 parts of essence.

Embodiment 2

[0046] Specifically, the raw materials by weight are as follows:

[0047] The first component phase: 600 parts of water, 5 parts of guar gum hydroxypropyl trimethyl ammonium chloride, 5 parts of behenyloxy PG-trimethyl ammonium chloride, 10 parts of glycerin;

[0048] The second component phase: 150 parts of sodium laureth sulfate, 20 parts of sodium lauryl sulfate, 50 parts of disodium laureth sulfosuccinate;

[0049] The third component phase: 10 parts of cocamide MEA, 60 parts of cocamidopropyl betaine, 12 parts of acrylic acid (ester) / C10-30 alkanol acrylate crosslinked polymer;

[0050] The fourth component phase: 2 parts of titanium dioxide, 40 parts of silicone oil, 100 parts of polyquaternium-30;

[0051] Composition of the fifth component: 60 parts of Zanthoxylum bungeanum extract, 5 parts of preservatives, and 8 parts of essence.

example 3

[0053] Specifically, the raw materials by weight are as follows:

[0054] The first component phase: 500 parts of water, 3 parts of guar gum hydroxypropyl trimethyl ammonium chloride, 3 parts of behenyloxy PG-trimethyl ammonium chloride, 10 parts of glycerin;

[0055] The second component phase: 130 parts of sodium laureth sulfate, 15 parts of sodium lauryl sulfate, 30 parts of disodium laureth sulfosuccinate;

[0056] The third component phase: 8 parts of cocamide MEA, 55 parts of cocamidopropyl betaine, 11 parts of acrylic acid (ester) / C10-30 alkanol acrylate crosslinked polymer;

[0057] The fourth component phase: 1 part of titanium dioxide, 30 parts of silicone oil, 80 parts of polyquaternium-30;

[0058] Composition of the fifth component: 50 parts of Zanthoxylum bungeanum extract, 4 parts of preservatives, and 6 parts of essence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com