Forging method of high-carbon high-chromium steel forge piece and forge piece

A technology of high-carbon high-chromium steel and high-chromium steel, which is applied in the forging field of high-carbon high-chromium steel forgings and high-carbon high-chromium steel forgings. Effect of reducing fatigue strength and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

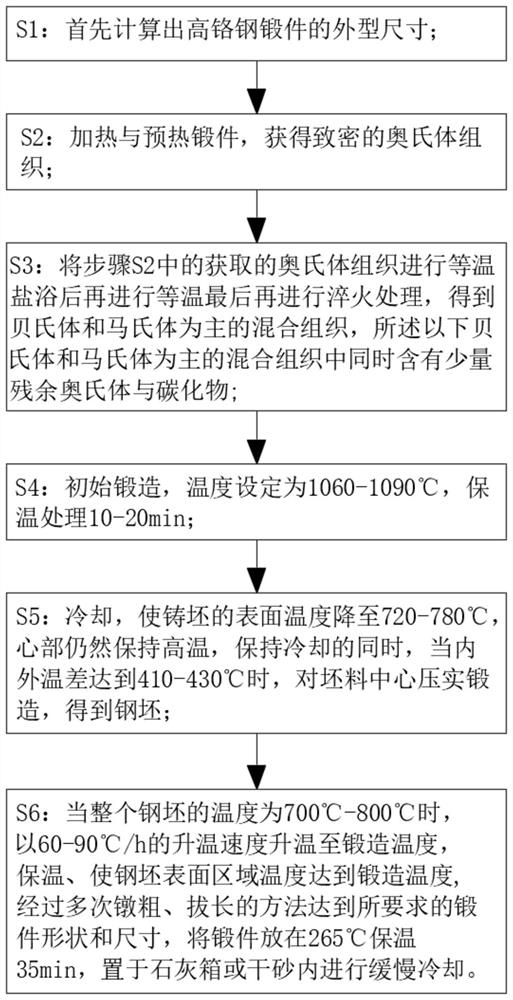

[0031] The present invention provides such figure 1 A forging method of a high-carbon high-chromium steel forging shown, comprising the steps of:

[0032] S1: First calculate the external dimensions of high chromium steel forgings;

[0033] S2: Heating and preheating the forging to obtain a dense austenite structure;

[0034] S3: The austenite structure obtained in step S2 is subjected to an isothermal salt bath, then isothermally and finally quenched to obtain a mixed structure dominated by bainite and martensite, the following bainite and martensite A small amount of retained austenite and carbides are contained in the mixed structure dominated by austenite;

[0035] S4: Initial forging, the temperature is set at 1060-1090°C, and the heat preservation treatment is 10-20min;

[0036] S5: Cooling, so that the surface temperature of the billet drops to 720-780°C, and the core remains at a high temperature. While maintaining cooling, when the temperature difference between th...

Embodiment 2

[0046] The column 1 contains the following components: by weight: 6 parts of carbon (C), 4 parts of manganese (Mn), 18 parts of silicon (Si), 18 parts of chromium (Cr) The content of nickel (Ni) is 10 parts, the content of nickel (Ni) is 18 parts, the content of sulfur (S) is less than 2 parts, and the content of phosphorus (P) is less than 1 part.

Embodiment 3

[0048] The column 1 contains the following components: by weight: 8 parts of carbon (C), 5 parts of manganese (Mn), 25 parts of silicon (Si), 25 parts of chromium (Cr) The content of nickel (Ni) is 15 parts, the content of nickel (Ni) is 22 parts, the content of sulfur (S) is less than 3 parts, and the content of phosphorus (P) is less than 1.5 parts.

[0049] Table 1, when implementing according to embodiment 1-3, its formula composition draws the following table:

[0050]

[0051] At present, the domestic high-carbon and high-chromium type cold-work die steel forgings in the domestic market have a maximum size specification of only Φ250mm, and are delivered according to the GB / T1299-2000 alloy tool steel standard. The standard stipulates that for steel with a diameter greater than 120mm, the qualified level of eutectic carbide unevenness is generally not greater than 6 (or the agreement between the supplier and the buyer), and the quality level of the steel cannot meet th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com