Pulley type aluminum mold transfer maneuvering device

A motorized device and pulley technology, applied in the direction of lifting device, lifting frame, building structure, etc., can solve the problems of complex and bulky structure of the aluminum mold transmission device of the motor, muscle injury of workers, and high power dependence, and achieve simple structure and applicability. Strong and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

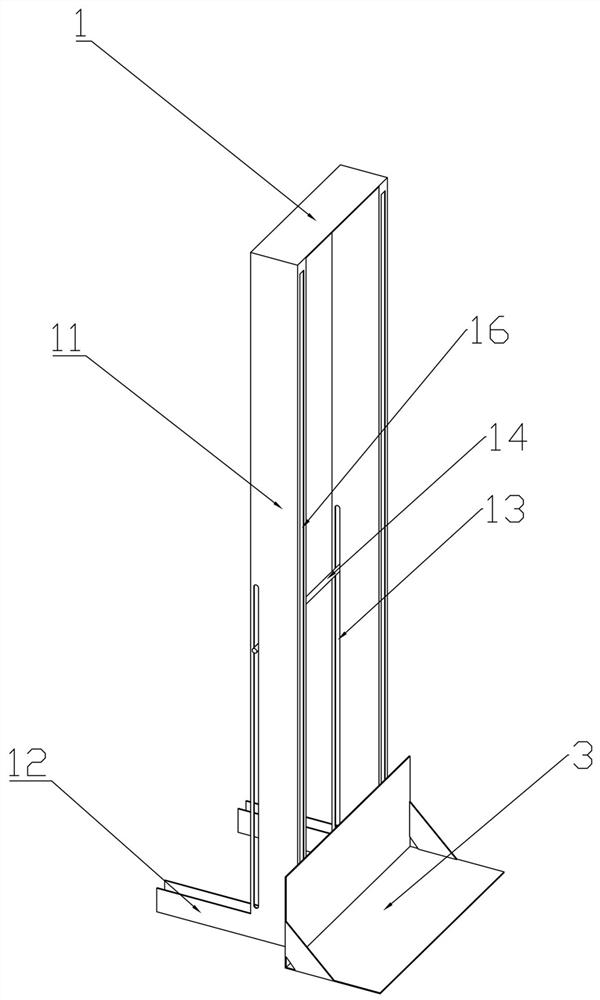

Method used

Image

Examples

Embodiment 2

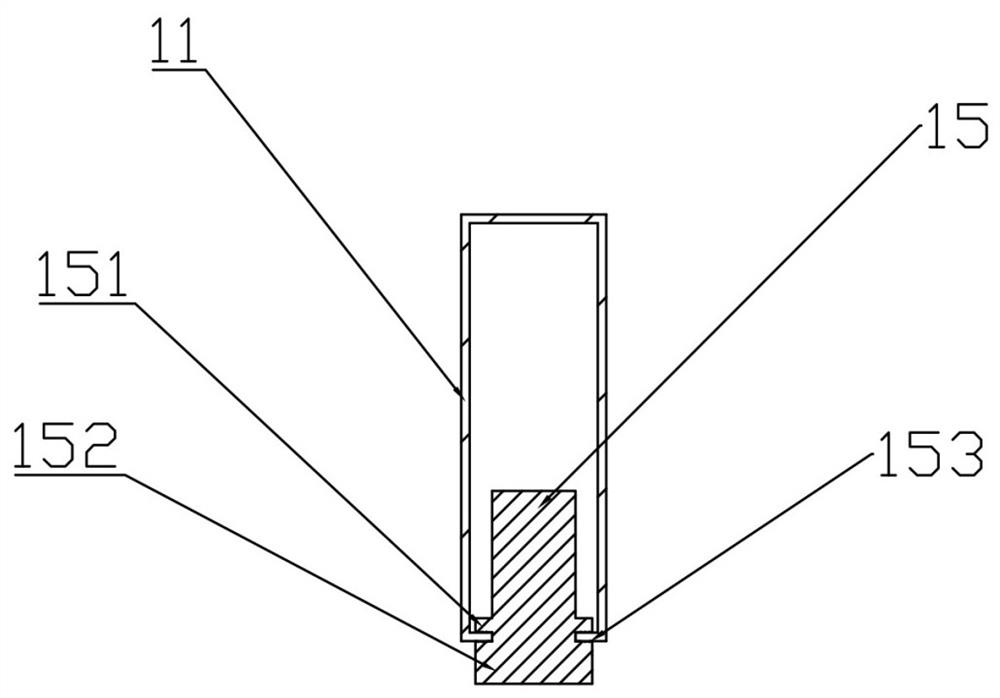

[0042] Embodiment 2: During the upward movement of the lifting plate, only rely on the pulling rope of the pulley to lift the connection block. The connection block 15 lacks a limit device during the upward movement, and it is easy to tilt due to unbalanced force. The inclined connection block The friction between the aluminum mold and the rectangular flat tube increases the friction force of the aluminum mold transfer, which makes the transfer process more laborious, and the device is easily damaged due to the friction between the two. In order to solve this problem.

[0043] Such as image 3 As shown, the connecting block 15 is centered on the bar-shaped sliding hole 16, and an inner limiting block 151 and an outer limiting block 152 are respectively arranged on the inner and outer sides of the bar-shaped sliding hole, between the inner limiting block 151 and the outer limiting block 152 A card slot is formed, and the card is sleeved on the side wall of the bar-shaped slidin...

Embodiment 3

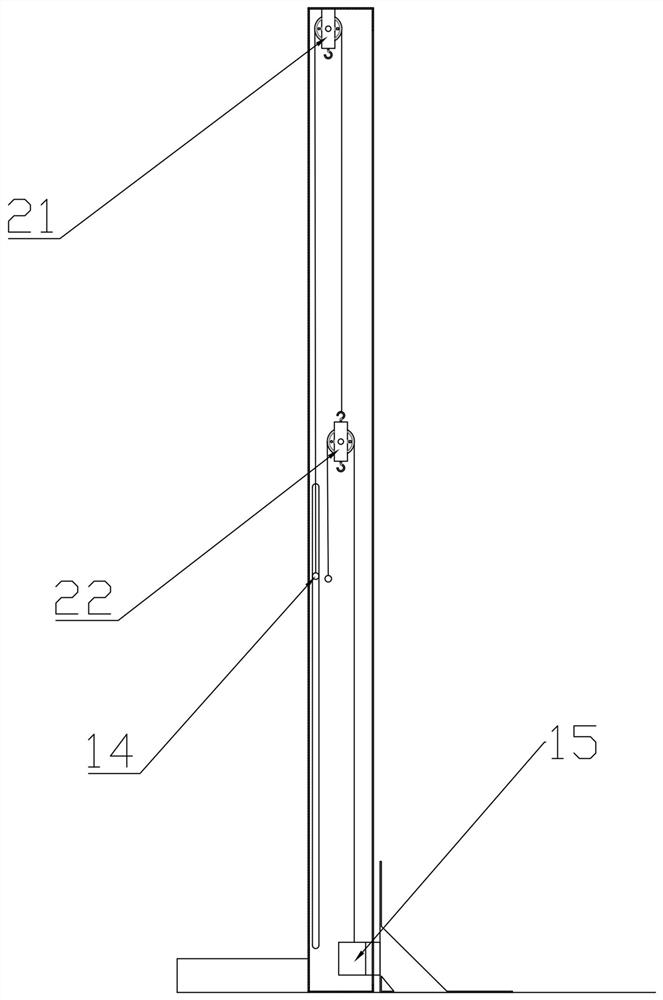

[0045] Embodiment 3: Due to the combination of the first pulley 21 and the second pulley 22, the pulley assembly is used to reduce the pulling amplitude of the worker and increase the distance of the aluminum mold, but this leads to the workers' in the process of passing the aluminum mold upwards. Need to use more force. Compared with equal-distance movement, this way of enlarging the distance requires more force when transferring the same weight of aluminum molds, and it will still cause a lot of physical exertion for construction workers.

[0046] In view of the above situation, the application is further as follows Figure 5 As shown, a counterweight 4 of appropriate weight is connected to the free end of the first pulley 21 to assist construction workers in pulling the pulley assembly, and reduce the burden of construction workers in pulling the pulley assembly. In order to drive the parallel pulley assemblies at the same time, the counterweight is installed on the synchr...

Embodiment 4

[0047] Embodiment 4: In order to further improve the transfer efficiency of the aluminum mold, as Figure 5-7 As shown, the pulley assembly also includes a third pulley 23, wherein one end of the stay rope of the second pulley 22 is fixed, and the other end is suspended to connect the third pulley 23, and one end of the stay rope of the third pulley 23 is wound on a rectangular flat On the corresponding fixed pin in the pipe, the other end of the third pulley stay cord is connected to the connecting block for installing and fixing the lifting plate.

[0048] Through the second pulley 22 and the third pulley 23 of the same structure, the movement ratio at both ends of the pulley assembly is further enlarged, the movement range of construction workers in the process of aluminum mold transfer is further reduced, the lower efficiency of aluminum mold transfer is improved, and the pulley-type aluminum mold transfer The motorized device transfers the aluminum mold to a higher height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com