Preparation method for extruding 3D printing silicon-aluminum oxide ceramic aerogel

A silicon-alumina oxide, 3D printing technology, used in ceramic products, other household appliances, inks, etc., can solve problems such as difficulty in applying additive manufacturing, achieve high structural integrity, high shape fidelity, and avoid structural damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

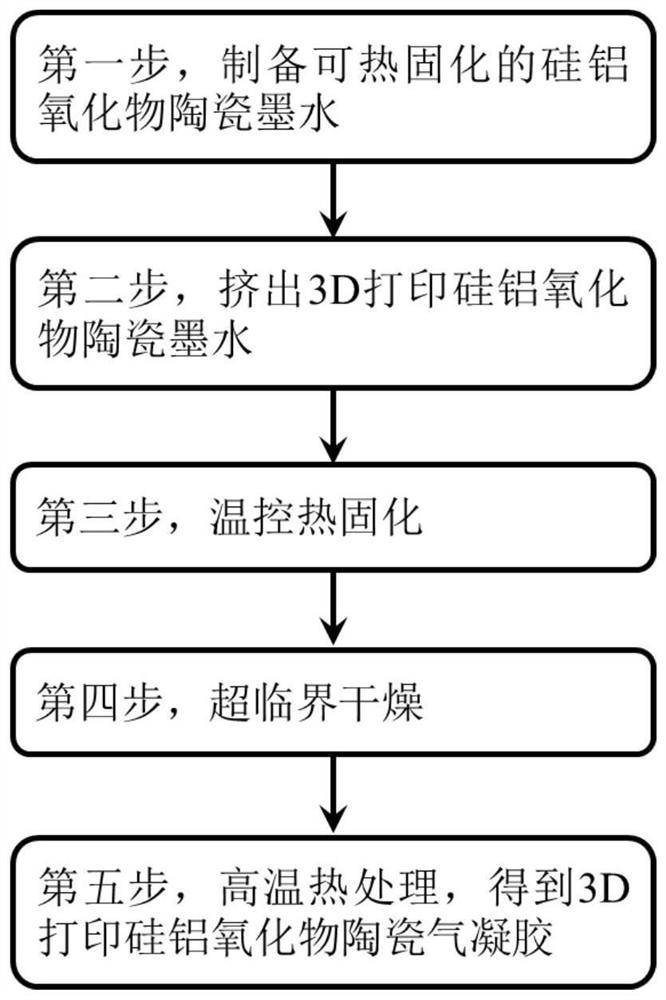

[0045] Such as figure 1 Shown, preparation embodiment 1 comprises the following steps:

[0046] The first step is to prepare thermally curable silicon aluminum oxide ceramic ink, the method is:

[0047] 1.1 The specific surface area is 400m 2 g -1 Fumed silica powder, 40wt% water-based silica sol, 20wt% water-based aluminum sol, polyvinyl alcohol, urea and water were mixed and stirred evenly to prepare the initial mixing slurry. In the ink composition, fumed silica powder, aqueous silica sol, aqueous aluminum sol, polyvinyl alcohol, urea and water account for 10, 30, 36, 1, 3, and 20 mass fractions of the silicon-aluminum oxide ceramic ink, respectively.

[0048] 1.2 Put the initial mixed slurry in a centrifugal defoaming mixer and stir for 3 minutes to obtain a silicon-aluminum oxide ceramic ink that is free of bubbles, heat-curable, and self-supporting. During the preparation process, the revolution speed of the mixer is controlled at 800rpm, and the rotation speed is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com