Method for separating yellow fluorescent substances from carbon quantum dots

A technology of carbon quantum dots and yellow fluorescence, which is applied in the field of separating yellow fluorescent substances, can solve the problems of unclear formation mechanism of fluorescent light sources of carbon quantum dots, unfavorable development and application of carbon quantum dots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method for separating the yellow fluorescent substance from the carbon quantum dots of the present embodiment comprises the following steps:

[0026] (1) 2 g of o-phenylenediamine was dissolved in 20 mL of absolute ethanol, sonicated for 15 min until the mixture was clear, then the mixture was transferred to a 100 mL polytetrafluoroethylene-lined stainless steel autoclave and heated at 180 °C for 8 h. When the autoclave was cooled to room temperature, a dark brown solution was obtained.

[0027] (2) Mix the dark brown solution with silica gel (greagent analytical grade, 200-300 mesh silica gel; the dosage is generally 3-5 g; in this example, the dosage is 3 g), and dry with a rotary evaporator. Take dichloromethane (DMC) and methanol as the eluent, mix with the mixture obtained by rotary evaporation (the amount of eluent can be 800-1000mL; the amount of this embodiment is 800mL), and elute through the chromatographic column, and the chromatographic column packing is...

Embodiment 2

[0029] The method for separating the yellow fluorescent substance from the carbon quantum dots of this embodiment differs from that of Embodiment 1 only in that:

[0030] In step (1), the consumption of o-phenylenediamine is 0.5g. The temperature of the solvothermal reaction was 180°C, and the heating time was 7h.

Embodiment 3

[0032] The method for separating the yellow fluorescent substance from the carbon quantum dots of this embodiment differs from that of Embodiment 1 only in that:

[0033] In step (1), the consumption of o-phenylenediamine is 3g. The temperature of the solvothermal reaction was 190°C, and the heating time was 9h.

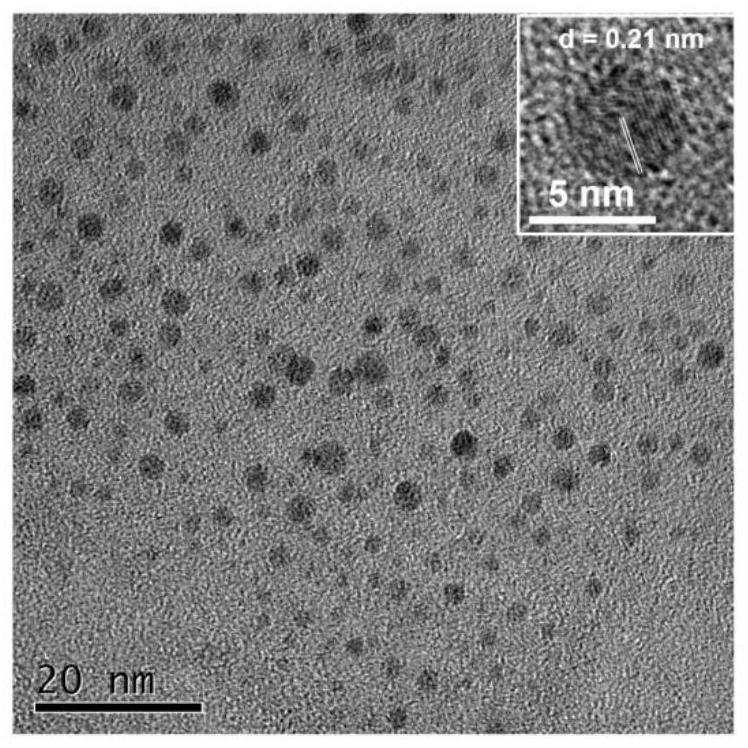

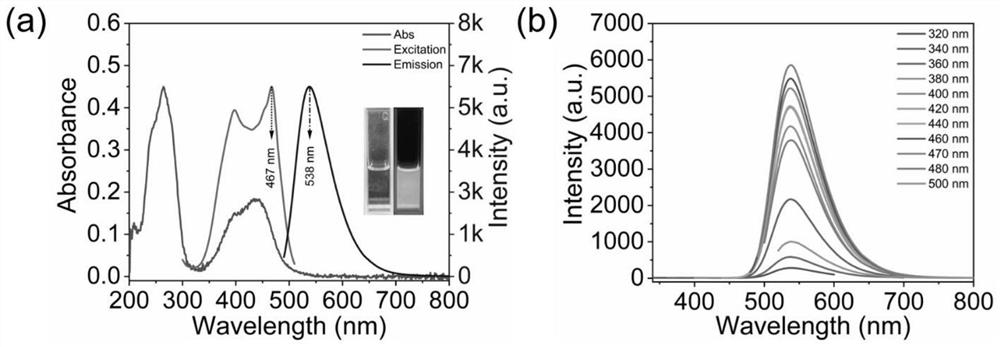

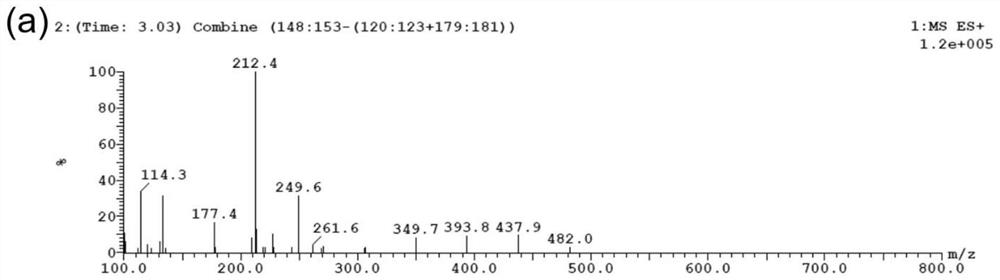

[0034] 2. Experimental example

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com