A fluorescent amino carbon quantum dot and its preparation method and application

An amino carbon quantum and fluorescence technology, applied in the fields of optics, polymer and biomass chemical industry, can solve the problems of time-consuming and expensive, achieve good biocompatibility, improve quantum yield, and change the effect of fluorescence properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

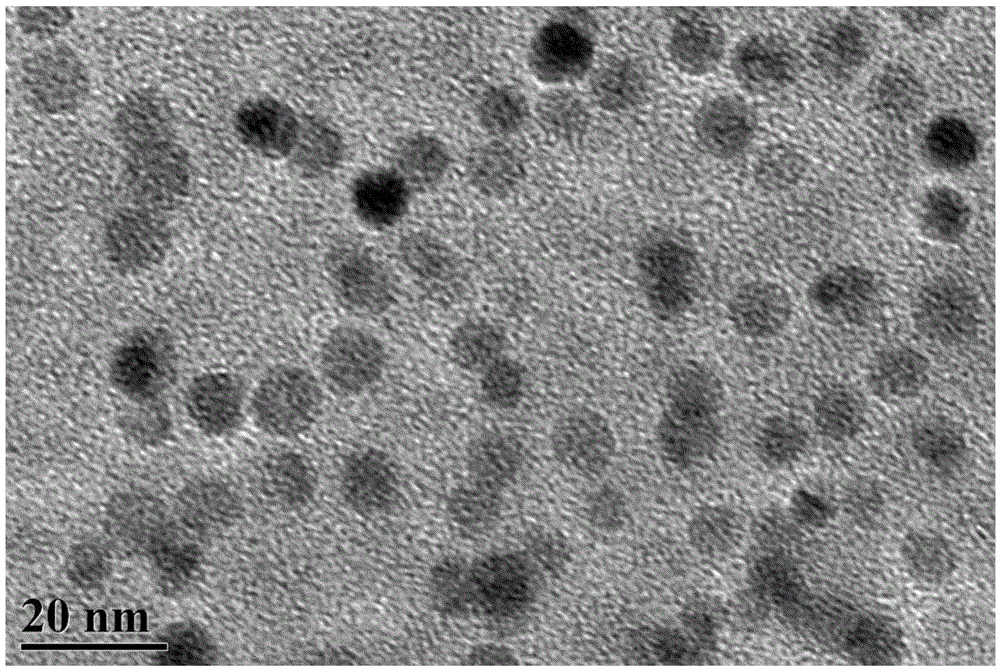

[0036] Weigh 1.000 g of purified xylan, add 19 mL of 2% ammonia solution (v / v), stir magnetically until completely dispersed, and the mixture becomes an khaki opaque suspension. The mixture was transferred into a 25mL polytetrafluoroethylene reactor with a stainless steel outer lining, sealed and placed in a muffle furnace, and hydrothermally treated (200°C) for 12h. After the reaction was over, the reactor was taken out and cooled to room temperature in air. The product is a dark brown liquid and gray-black precipitate with a strong ammonia smell. Move the product to a beaker, and ultrasonically disperse it in an ultrasonic cleaner with a power of 70W, time of 1h, and temperature at room temperature. Then, the product was refrigerated and centrifuged at 15000 rpm, 0° C. for 15 min, and repeated twice. A dark brown supernatant and a large amount of powdery precipitates are obtained. After removing the precipitates, an aqueous solution of amino carbon quantum dots is obtained...

Embodiment 2

[0046]Weigh 1.000 g of purified xylan, add 19 mL of 2% sodium hydroxide aqueous solution (w / v), stir magnetically until completely dispersed, and the mixture becomes an orange-yellow transparent solution. The mixture was transferred into a 25mL polytetrafluoroethylene reactor with a stainless steel outer lining, sealed and placed in a muffle furnace, and hydrothermally treated (200°C) for 12h. After the reaction was over, the reactor was taken out and cooled to room temperature in air. The product is a dark brown liquid and a small amount of gray-black precipitate. Move the product to a beaker, and ultrasonically disperse it in an ultrasonic cleaner with a power of 70W, time of 1h, and temperature at room temperature. Then, the product was refrigerated and centrifuged at 15000 rpm, 0° C. for 15 min, and repeated twice. A dark brown supernatant and a small amount of powdery precipitate were obtained, and after the precipitate was removed, an aqueous solution of ammonia-free c...

Embodiment 3

[0053] Weigh 1.000 g of purified xylan, add 19 mL of 25% ammonia solution (v / v), stir magnetically until completely dispersed, and the mixture becomes an khaki opaque suspension. The mixture was transferred into a 25mL polytetrafluoroethylene reactor with a stainless steel outer lining, sealed and placed in a muffle furnace, and hydrothermally treated (200°C) for 6h. After the reaction was over, the reactor was taken out and cooled to room temperature in air. The product is a dark brown liquid and gray-black precipitate with a strong ammonia smell. Move the product to a beaker, and ultrasonically disperse it in an ultrasonic cleaner with a power of 70W, time of 1h, and temperature at room temperature. Then, the product was refrigerated and centrifuged at 15000 rpm, 0° C. for 15 min, and repeated 3 times. A dark brown supernatant and a large amount of powdery precipitates are obtained. After removing the precipitates, an aqueous solution of amino carbon quantum dots is obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com