Resin toughening composition, resin toughening modifier, modified bismaleimide resin composition, and cured product

A technology of bismaleimide resin and bismaleimide, which is applied in the field of modified bismaleimide resin composition and cured product, can solve the problem of poor toughness of bismaleimide resin and reduce the Bismaleimide resin performance and scope of use and other issues, to achieve toughness enhancement, expand the performance and scope of use, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

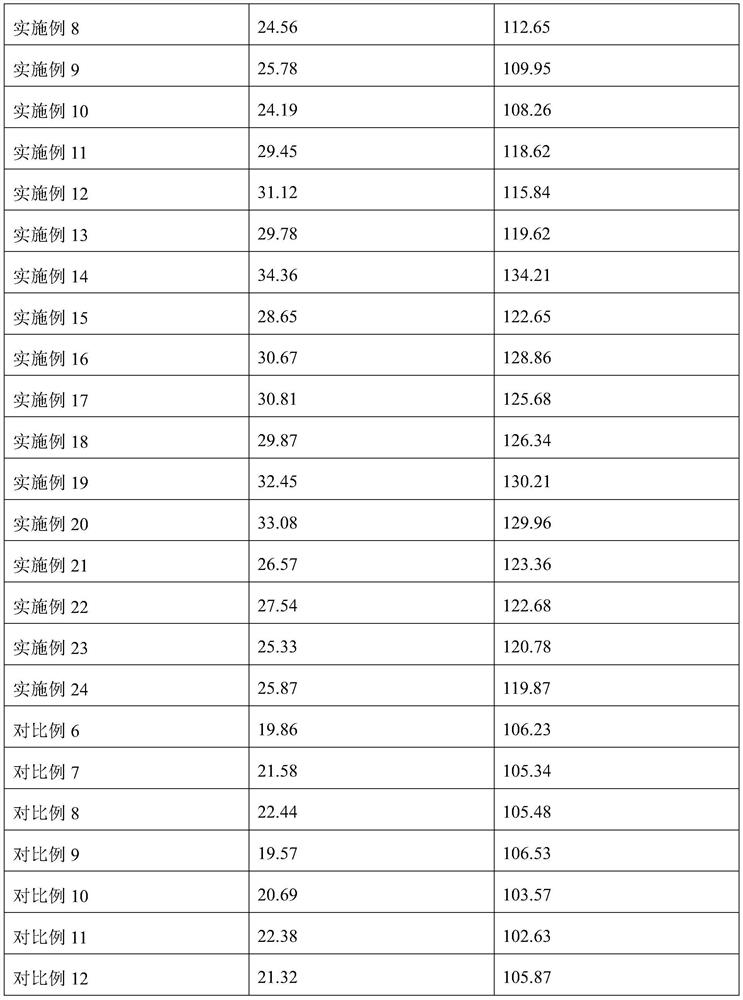

Examples

preparation example Construction

[0027] In some embodiments of the present application, the preparation method of the resin toughening modifier includes: step S1, performing an addition reaction of diphenylmethane bismaleimide and diaminodiphenylmethane to obtain an addition product system; In step S2, the addition product in the addition product system is subjected to a ring-opening reaction with bisphenol A diglycidyl ether to obtain a resin toughening modifier.

[0028] In above-mentioned step S1, diaminodiphenylmethane and diphenylmethane bismaleimide add reaction, when expanding the molecular chain of diphenylmethane bismaleimide, introduce active The amino group of hydrogen is conducive to the subsequent reaction of the active hydrogen on the amino group with the substance containing the flexible chain to introduce a flexible group.

[0029] In some preferred embodiments of the present application, step S1 includes: A, dissolving diphenylmethane bismaleimide and diaminodiphenylmethane in a solvent respe...

Embodiment 1

[0065] This embodiment provides a resin toughening modifier, which is prepared according to the following steps:

[0066] (1) Dissolve 30g of diphenylmethane bismaleimide in 200mL N,N-dimethylacetamide, stir evenly to completely dissolve diphenylmethane bismaleimide in N,N-dimethylacetamide in acetamide. Dissolve 30g of diaminodiphenylmethane in 250mL of N,N-dimethylacetamide, and stir evenly to completely dissolve the diaminodiphenylmethane in N,N-dimethylacetamide. Mix the above two solutions, stir and react at 80-90°C for 30 minutes, pour the above solution into distilled water after the reaction, cool and crystallize at 20-30°C, then filter and dry to obtain the addition product.

[0067] (2) Heat 40g of bisphenol A diglycidyl ether at 80-90°C for 30 minutes, add the addition product, heat at 90-100°C for 40-50 minutes, and cool to obtain a resin toughening modifier.

Embodiment 2

[0069] This embodiment provides a resin toughening modifier, which is prepared according to the following steps:

[0070] (1) Dissolve 55g of diphenylmethane bismaleimide in 400mL N,N-dimethylacetamide, stir evenly to completely dissolve diphenylmethane bismaleimide in N,N-dimethylacetamide in acetamide. Dissolve 15g of diaminodiphenylmethane in 130mL of N,N-dimethylacetamide, and stir evenly to completely dissolve the diaminodiphenylmethane in N,N-dimethylacetamide. Mix the above two solutions, stir and react at 80-90°C for 30 minutes, pour the above solution into distilled water after the reaction, cool and crystallize at 20-30°C, then filter and dry to obtain the addition product.

[0071] (2) Heat 30 g of bisphenol A diglycidyl ether at 80-90°C for 30 minutes, add the addition product, heat at 90-100°C for 40-50 minutes, and cool to obtain a resin toughening modifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com