Two-component anti-sagging polyurethane waterproof coating and preparation method thereof

A polyurethane waterproof and anti-sag technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor anti-sag performance, long surface dry time and hard drying time, and improve construction applicability, surface The effect of shortening the drying time and shortening the hard drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Prepare Component A; prepare each raw material as follows:

[0052] Polyether 2000 Blue Star Dongda 650kg

[0053] Polyether 1000 Blue Star Dongda 50kg

[0054] MDI-MI BASF 350kg

[0055] Add polyether 2000 and polyether 1000 to the reaction kettle that can be heated and vacuumed, start stirring at 25HZ / min, turn on the vacuum, the vacuum requirement is below -0.09MPa, slowly raise the temperature to 110°C, and vacuum dehydrate for 3 hours to reach the moisture content The content is less than 0.05%. Lower the temperature to 60°C, add isocyanate, then control the temperature at 80±2°C, and pass nitrogen protection reaction for 3h while stirring. After the reaction is completed, turn on the vacuum to below -0.9MPa, vacuumize and degas for 1 hour, cool the liquid material to below 80°C, and discharge the material for packaging.

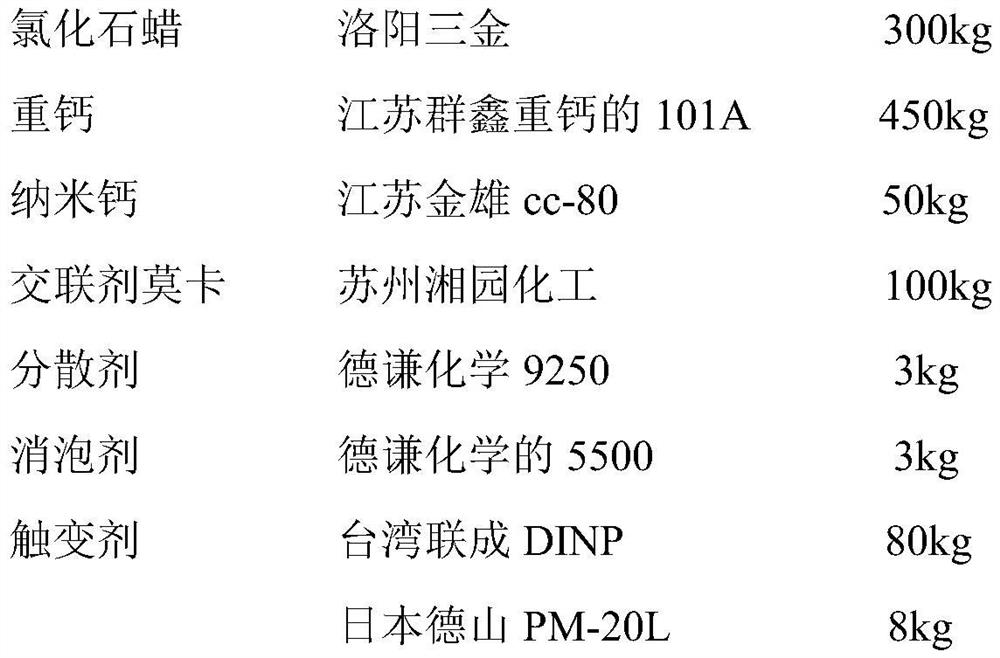

[0056] Prepare Component B; prepare each raw material as follows:

[0057]

[0058] The thixotropic agent was obtained by uniformly disp...

Embodiment 2

[0064] Basically the same as Example 1, the only difference is: when preparing component B, add 25kg diluent 230# solvent oil while adding dispersant, defoamer and thixotropic agent.

[0065] The performance of the waterproof coating of this embodiment is as follows:

[0066] The waterproof coating after mixing components A and B according to the mass ratio of 1:2 has a viscosity of 16200mpa*s at 23°C, a solid content of 98.2%, a surface-drying time of 3.5 hours, a hard-drying time of 11 hours, and 7 days The tensile strength is 7.3MPa, the elongation at break is 590%, and the surface dry time of the product is long, which is close to the minimum limit required by the standard.

[0067] The situation of scraping construction on the facade is as follows: a thick coating of 2mm flows, and a thick coating of 1mm does not flow.

Embodiment 3

[0069] Basically the same as Example 1, the only difference is that the amount of thixotropic agent in component B is changed from 8kgPM20L+80kgDINP predispersion to 6kgPM20L+80kgDINP predispersion.

[0070] The performance of the waterproof coating of this embodiment is as follows:

[0071] The waterproof coating after mixing components A and B according to the mass ratio of 1:2 has a viscosity of 29200mpa*s at 23°C, a solid content of 99.9%, a surface-drying time of 2.5 hours, a hard-drying time of 8 hours, and 7 days The tensile strength was 7.9 MPa, and the elongation at break was 677%.

[0072] The situation of scraping construction on the facade is as follows: a thick coating of 2mm flows, and a thick coating of 1mm does not flow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com