Polyurethane adhesive and application thereof in adhering exterior wall insulation material and construction method of polyurethane adhesive

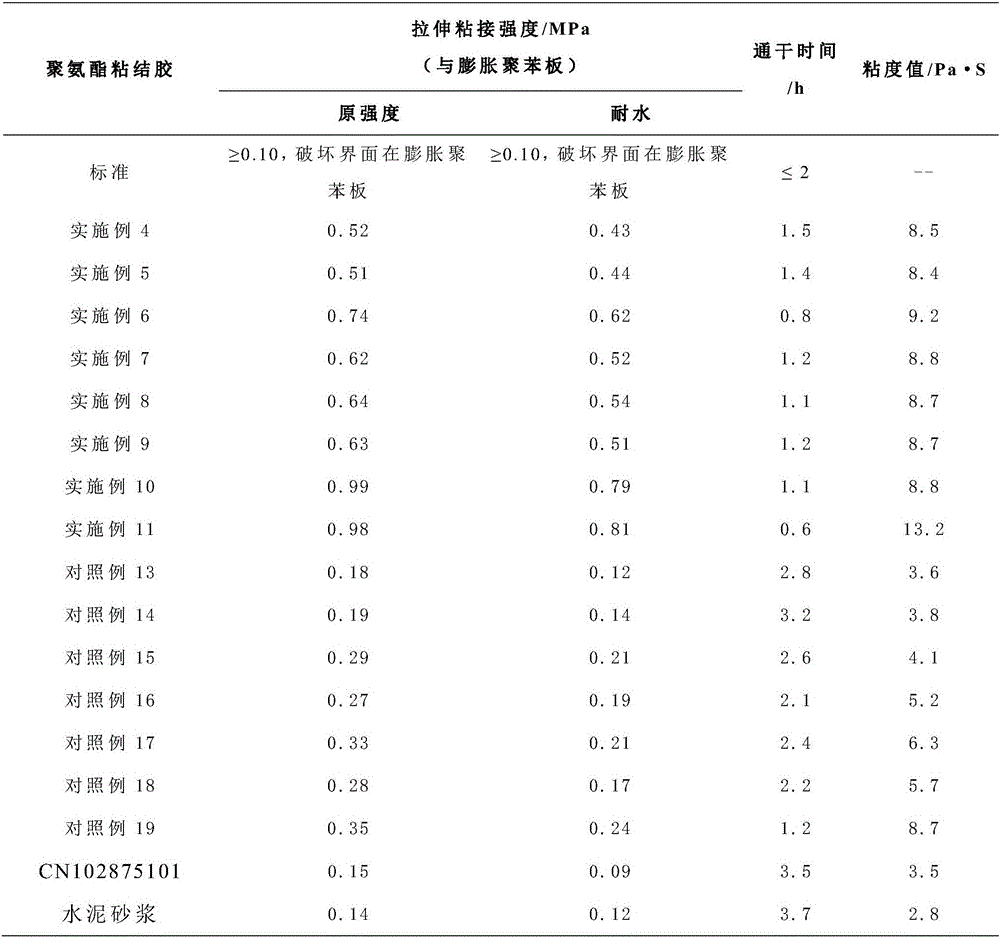

An external wall thermal insulation, polyurethane technology, applied in the field of polyurethane adhesive, can solve the problems of dust and ash, easy to fall off, low bonding strength, etc., and achieve high tensile bonding strength, high tensile bonding strength, tensile strength The effect of high tensile bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

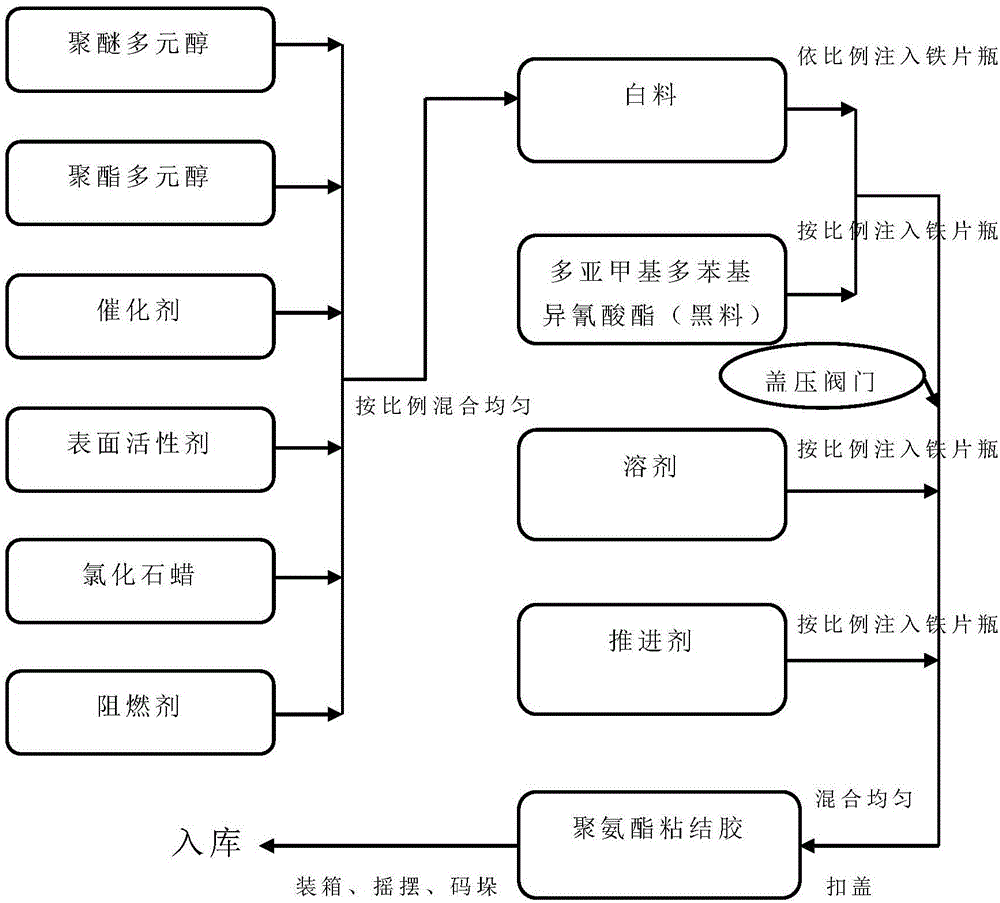

Method used

Image

Examples

Embodiment 1

[0052] This embodiment provides the application of a polyurethane adhesive in bonding external wall insulation materials. The polyurethane adhesive is composed of the following components by weight percentage:

[0053] Polyether polyol 10% Polyester polyol 10%

[0054] Polymethylene polyphenylisocyanate 50% flame retardant 5%

[0055] Bismorpholino diethyl ether 0.5% Silicone oil surfactant 2%

[0056] Chlorinated Paraffin 5% Dimethyl Ether 7.5% Propane Butane 10%.

Embodiment 2

[0058] This embodiment provides the application of a polyurethane adhesive in bonding the external wall insulation material to the external wall, wherein the polyurethane adhesive is composed of the following components by weight percentage:

[0059] Polyether polyol 15% Polyester polyol 12%

[0060] Polymethylene polyphenylisocyanate 35% flame retardant 7.8%

[0061] Bismorpholino diethyl ether 0.2% Silicone oil surfactant 1%

[0062] Chlorinated paraffin 15% dimethyl ether 9% propylene butane 5%.

Embodiment 3

[0064] This embodiment provides the application of a polyurethane adhesive in bonding the thermal insulation polystyrene board to a building wall with a cement surface, wherein the polyurethane adhesive is composed of the following components by weight percentage:

[0065] Polyether polyol 16% Polyester polyol 1%

[0066]Polymethylene polyphenylisocyanate 47% Flame retardant 1%

[0067] Dimorpholino diethyl ether DMDEE 0.4% Silicone oil surfactant 1.2%

[0068] Chlorinated Paraffin 20% Chlorine 52% Dimethyl Ether 6.5%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com