Bridge expansion joint protective glue with shape self-adaptability

An adaptive, expansion joint technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problem of sealing and protection of bridge expansion joints, unsatisfactory adhesion of steel structures, and poor adaptability and other problems to achieve the effect of avoiding debonding in winter, avoiding rubber drumming in summer, and excellent elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

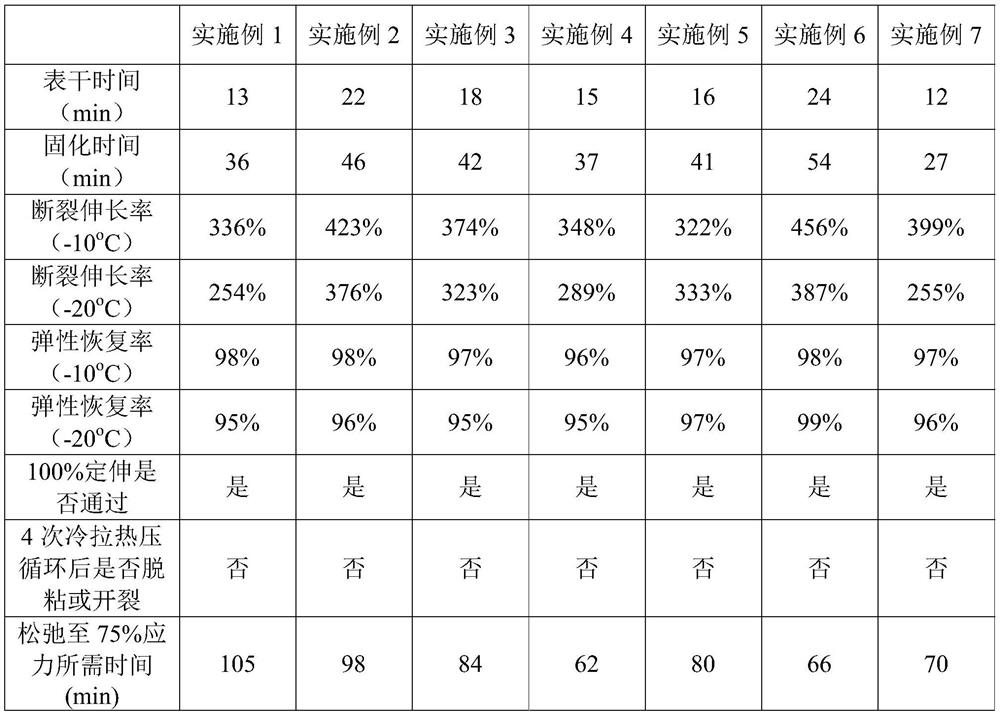

Examples

Embodiment 1

[0043] Step 1, the preparation of polyurethane prepolymer

[0044] 10 parts by mass of polyethylene glycol (Mn=2000) and 10 parts by mass of polyether polyol (Mn=3000) were heated in vacuum to remove water, then added to the reaction kettle, and 5 parts by mass of iso Phorne diisocyanate, 0.5 parts by mass of dibutyltin dilaurate, and 0.5 parts by mass of ethanolamine were reacted at 60 for 1 hour to obtain a polyurethane prepolymer;

[0045] Step 2, the preparation of A component

[0046] An equal blend of 5 parts by mass of dibutyl phthalate, 1 part by mass of BYK070, 7 parts by mass of talcum powder and calcium carbonate powder was added to a vacuum reactor to remove water, and then the prepared 30 Parts by mass of polyurethane prepolymer, 1 part by mass of dibutyltin dilaurate, and 0.5 parts by mass of trimethyl orthoformate are added, mixed in a vacuum environment, sealed and stored to obtain component A;

[0047] Step 3, preparation of curing agent

[0048] Mix and st...

Embodiment 2

[0053] Step 1, the preparation of polyurethane prepolymer

[0054] 50 parts by mass of polyethylene glycol (Mn=2000) and 40 parts by mass of polyether polyol (Mn=3000) were heated in a vacuum to remove water, then added to the reactor, and 20 parts by mass were added under nitrogen protection. Parts of toluene diisocyanate and equal blends of diphenylmethane diisocyanate, 1 mass part of diethanolamine, 1 mass part of stannous octoate, reacted at 70 for 2 hours to obtain a polyurethane prepolymer;

[0055] Step 2, the preparation of A component

[0056] 10 parts by mass of dioctyl phthalate, an equal blend of ethyl acetate, 5 parts by mass of BYK024 and an equal amount of HX-2085, 20 parts by mass of kaolin and silica powder The blend is added to a vacuum reactor to remove water, and then the obtained 60 mass parts of polyurethane prepolymer, 5 mass parts of dibutyltin dilaurate, and 2 mass parts of trimethyl orthoformate are added, and the Mixed under the environment, sealed...

Embodiment 3

[0063] Step 1, the preparation of polyurethane prepolymer

[0064] 45 parts by mass of polyethylene glycol (Mn=4000) and 25 parts by mass of polyether polyol (Mn=5000) were heated in a vacuum to remove water, then added to the reactor, and 15 parts by mass were added under nitrogen protection. 1,6-hexamethylene diisocyanate and 1 mass part of dibutyltin dilaurate and 0.6 mass part of ethanolamine reacted at 80 for 1 hour to obtain a polyurethane prepolymer;

[0065] Step 2, the preparation of A component

[0066] Add 8 parts by mass of ethyl acetate, butyl acetate and an equal blend of butyl acetate, 3 parts by mass of BYK024, 7 parts by mass of talcum powder, and 6 parts by mass of diatomaceous earth into a vacuum reactor for removal. water, and then the obtained 45 parts by mass of polyurethane prepolymer, 3 parts by mass of dibutyltin dilaurate, and 1 part by mass of trimethyl orthoformate were added, mixed in a vacuum environment, sealed and stored to obtain Group A Minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com