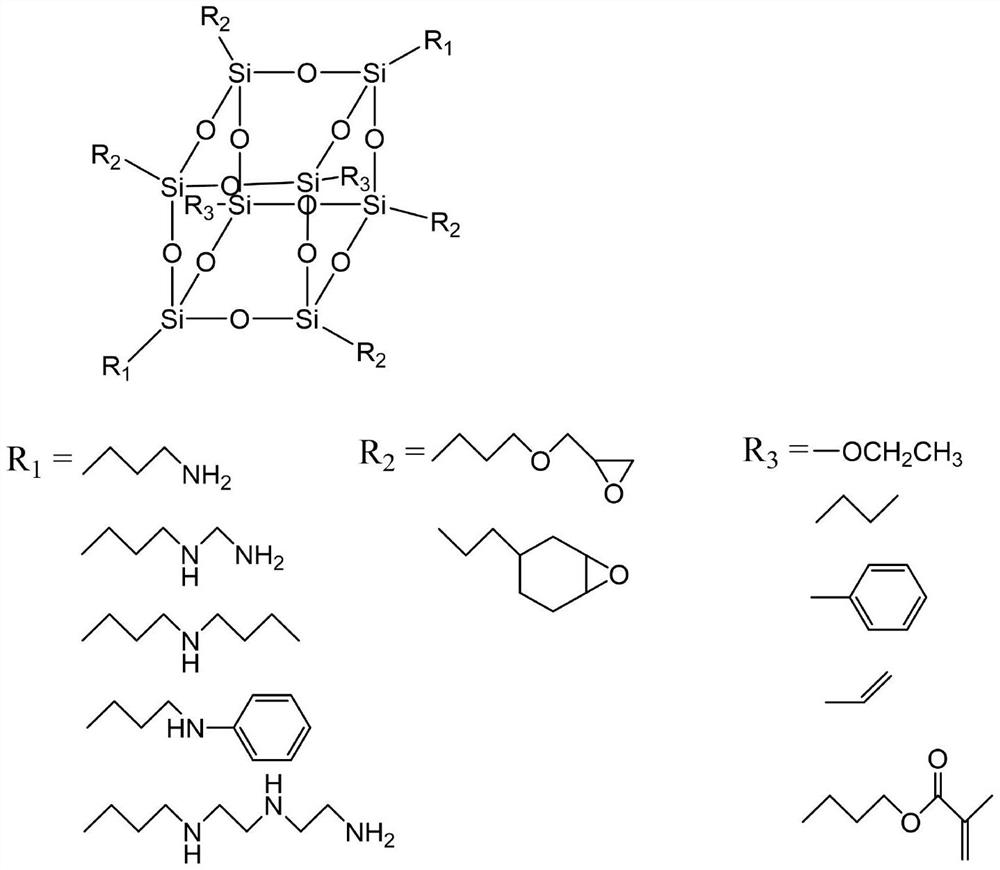

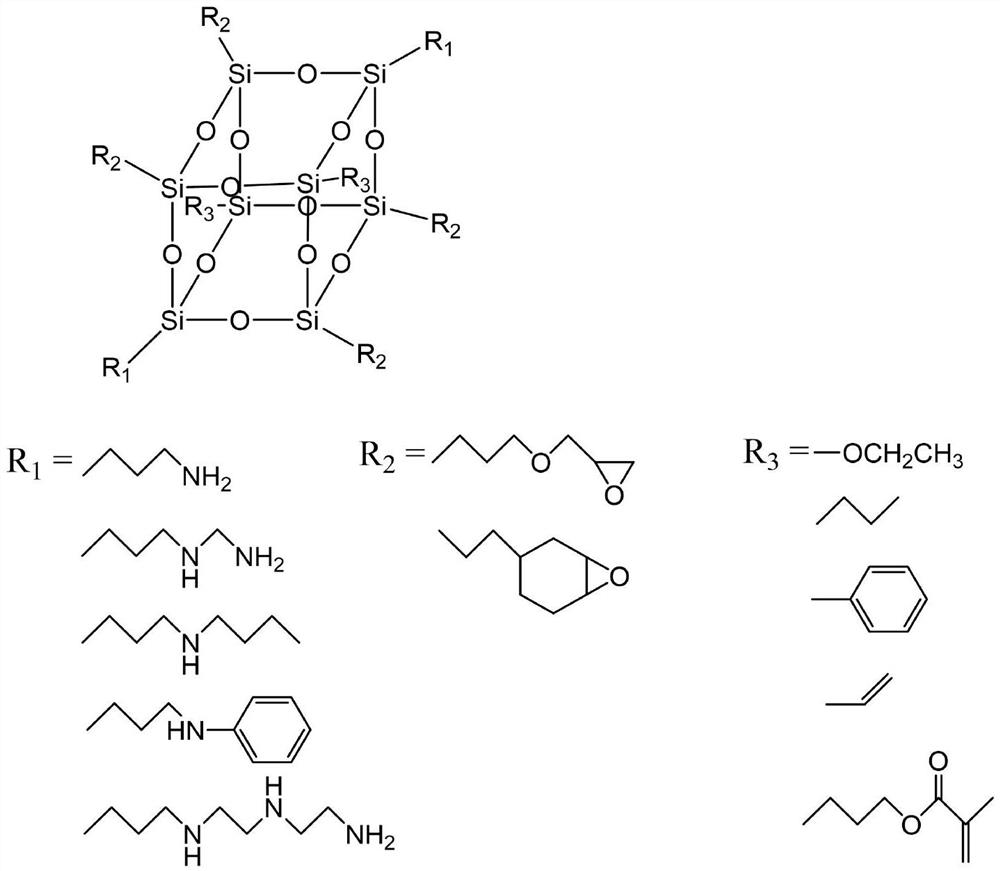

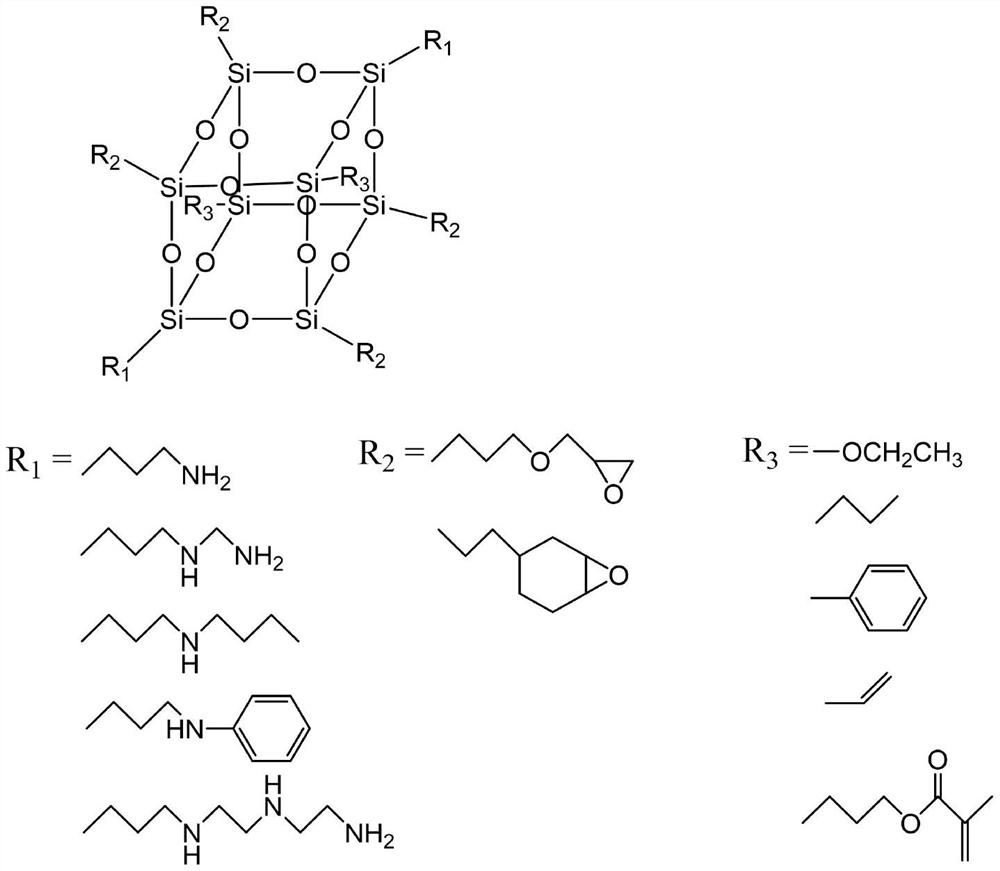

Synthesis method of polysilsesquioxane coupling agent for RTV (Room Temperature Vulcanization) silicone rubber and ketoxime-removed silicone rubber

The technology of a siloxane coupling agent and an aminosilane coupling agent is applied to the synthesis method of a polysilsesquioxane coupling agent and the field of deketoxime type silicone rubber, which can solve the problem of large randomness of the viscosity of the target product and increase production. Time, difficult to obtain coupling agent and other problems, to achieve the effect of large market application and development potential, reduce solvent cost, and improve synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In a 250mL three-necked flask, add 20g of aminopropyltriethoxysilane, 20g of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 20g of ethyl orthosilicate, 0.2g of pure Water and 1 g of triethylamine were used as hydrolysis accelerators. After the addition was completed, the stirring was turned on at a rotation speed of 100 rpm, and the temperature of the oil bath was raised to 65° C., and the reaction was stirred for 1.5 hours. After the reaction is completed, carry out distillation. At a vacuum degree of 0.09-0.1MPa and a temperature of 80°C, after distillation for 1 hour, a colorless and transparent liquid product is obtained. The coupling agent does not have a viscosity peak in the production of the rubber material, and the rubber material is not yellow. Change, viscosity 62mPa·s.

[0027] Preparation steps of deketoxime type silicone rubber: at room temperature, mix 100 parts of 107 glue, 150 parts of nano-calcium, 11 parts of methyl silicone oil, 10 parts of methyl trib...

Embodiment 2

[0029] In a 250mL three-necked flask, add 20g of aminopropyltriethoxysilane, 20g of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 20g of ethyl orthosilicate, 0.5g of pure Water and 1 g of triethylamine were used as hydrolysis accelerators. After the addition was completed, the stirring was turned on at a rotation speed of 100 rpm, and the temperature of the oil bath was raised to 65° C., and the reaction was stirred for 1.5 hours. After the reaction is completed, carry out distillation. At a vacuum degree of 0.09-0.1MPa and a temperature of 80°C, after distillation for 1 hour, a colorless and transparent liquid product is obtained. The coupling agent does not have a viscosity peak in the production of the rubber material, and the rubber material is not yellow. Change, viscosity 237mPa·s.

[0030] Preparation steps of deketoxime type silicone rubber: at room temperature, mix 100 parts of 107 glue, 150 parts of nano-calcium, 11 parts of methyl silicone oil, 10 parts of methyl tri...

Embodiment 3

[0032] In a 250mL three-necked flask, add 20g of aminopropyltriethoxysilane, 20g of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 20g of ethyl orthosilicate, 0.8g of pure Water and 1 g of triethylamine were used as hydrolysis accelerators. After the addition was completed, the stirring was turned on at a rotation speed of 100 rpm, and the temperature of the oil bath was raised to 65° C., and the reaction was stirred for 1.5 hours. After the reaction is completed, carry out distillation. At a vacuum degree of 0.09-0.1MPa and a temperature of 80°C, after distillation for 1 hour, a colorless and transparent liquid product is obtained. The coupling agent does not have a viscosity peak in the production of the rubber material, and the rubber material is not yellow. Change, viscosity 259mPa·s.

[0033] Preparation steps of deketoxime type silicone rubber: at room temperature, mix 100 parts of 107 glue, 150 parts of nano-calcium, 11 parts of methyl silicone oil, 10 parts of methyl tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com