30MnSi wire rod steel and preparation method thereof

A wire rod and bar steel technology, applied in the field of 30MnSi wire rod steel and its preparation, can solve problems such as steel weight loss, and achieve the effects of low mold damage, excellent scale thickness and peeling performance, and high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The chemical composition and mass percentage of 30MnSi wire rod for PC rods are: C: 0.28%, Si: 0.85%, Mn: 0.95%, Si / Mn: 0.89, P: 0.010%, S: 0.009%, and the balance is Fe and Unavoidable impurities.

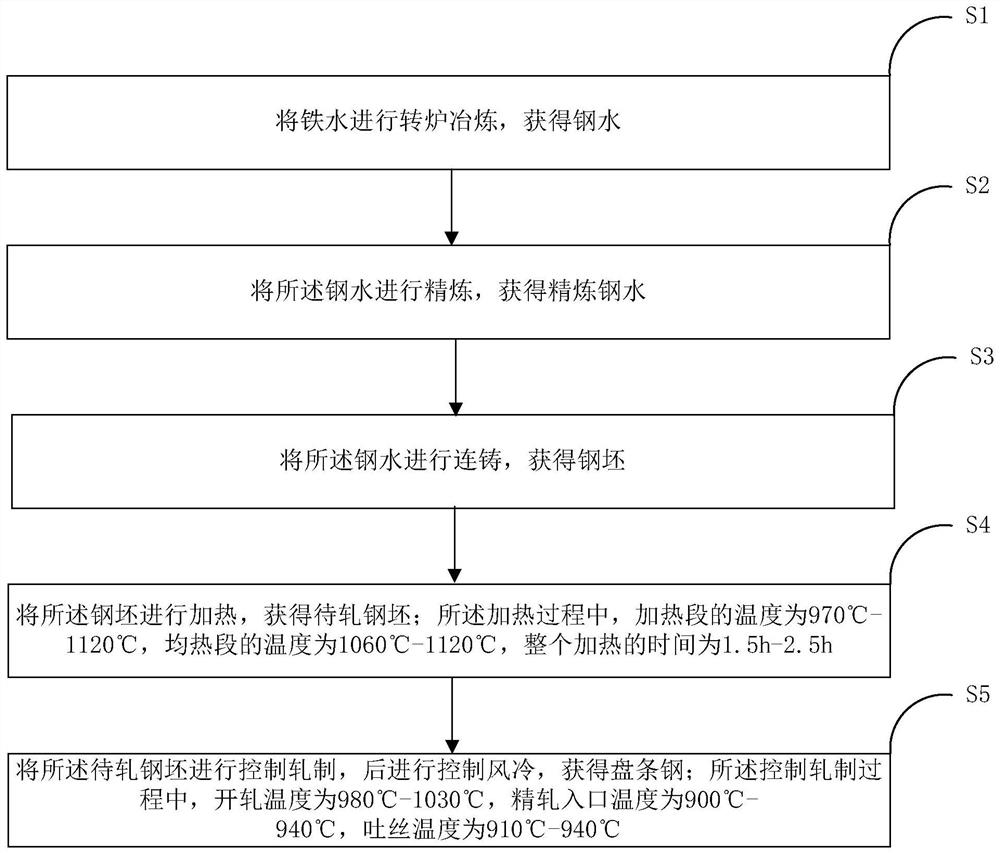

[0051] The production process of 30MnSi wire rod for PC rod is as follows:

[0052] Molten iron→converter smelting→alloy addition→LF refining→continuous casting into billet→heating in heating furnace→controlled rolling→controlled air cooling.

[0053] The steelmaking process and control are as follows: alloy is added at the end of the converter, continuous casting adopts full protection pouring, and the superheat is 30°C.

[0054] The steel rolling process and control are as follows: the temperature of the heating section of the heating furnace is 980°C, the temperature of the soaking section is 1070°C, the time in the furnace is 2 hours, the starting temperature of rolling is 985°C, the entrance temperature of finishing rolling is 900°C, the spinning temperature is 910°C,...

Embodiment 2

[0056] The chemical composition and mass percentage of 30MnSi wire rod for PC rod are: C: 0.29%, Si: 0.93%, Mn: 1.00%, Si / Mn: 0.93, P: 0.013%, S: 0.012%, and the balance is Fe and Unavoidable impurities.

[0057] The production process of 30MnSi wire rod for PC rod is as follows:

[0058] Molten iron→converter smelting→alloy addition→LF refining→continuous casting into billet→heating in heating furnace→controlled rolling→controlled air cooling.

[0059] The steelmaking process and control are as follows: alloy is added at the end of the converter, continuous casting adopts full protection pouring, and the superheat is 30°C.

[0060] The steel rolling process and control are as follows: the temperature of the heating section of the heating furnace is 1050°C, the temperature of the soaking section is 1090°C, the time in the furnace is 2 hours, the starting temperature of rolling is 1000°C, the entrance temperature of finishing rolling is 920°C, the spinning temperature is 925°C...

Embodiment 3

[0062] The chemical composition and mass percentage of 30MnSi wire rod for PC rods are: C: 0.30%, Si: 0.98%, Mn: 1.04%, Si / Mn: 0.94, P: 0.018%, S: 0.019%, and the balance is Fe and Unavoidable impurities.

[0063] The production process of 30MnSi wire rod for PC rod is as follows:

[0064] Molten iron→converter smelting→alloy addition→LF refining→continuous casting into billet→heating in heating furnace→controlled rolling→controlled air cooling.

[0065] The steelmaking process and control are as follows: alloy is added at the end of the converter, continuous casting adopts full protection pouring, and the superheat is 30°C.

[0066] The steel rolling process and control are as follows: the temperature of the heating section of the heating furnace is 1120°C, the temperature of the soaking section is 1120°C, the time in the furnace is 2 hours, the starting temperature of rolling is 1030°C, the entrance temperature of finishing rolling is 940°C, the spinning temperature is 940°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com