Hydrogen compression material as well as preparation method and application thereof

A technology of hydrogen compressor and inert gas, which is applied in the field of hydrogen compression materials and its preparation, can solve the problems of waste in storage and transportation, and achieve the effects of reducing overall cost, stability, platform slope and hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

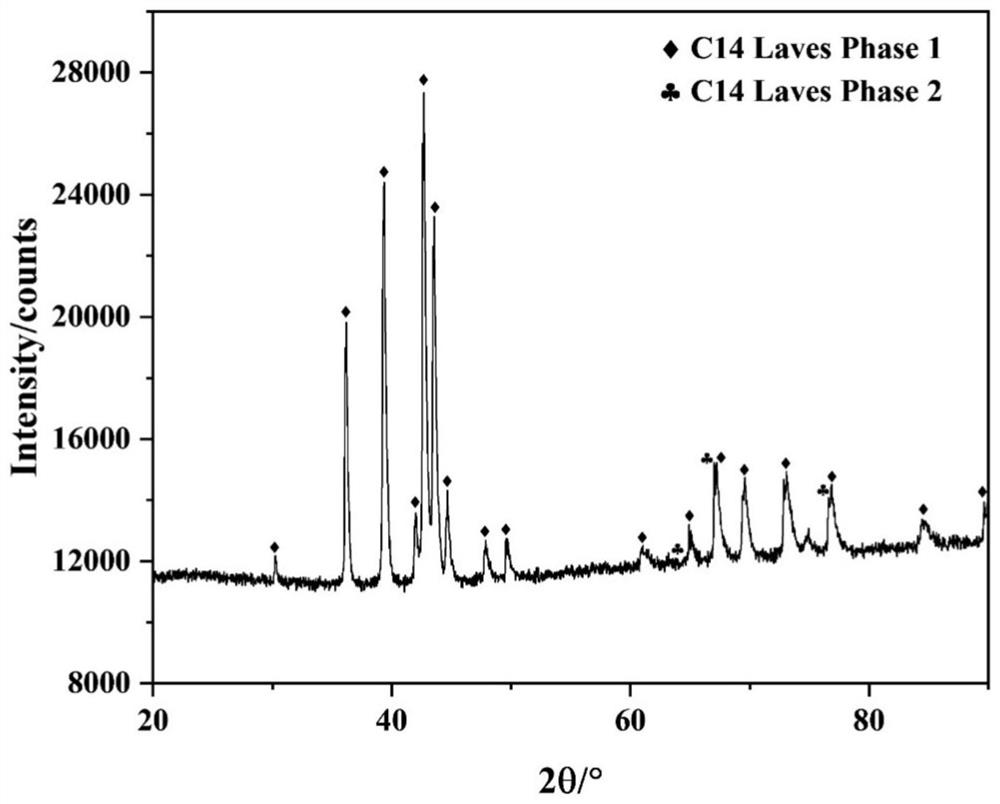

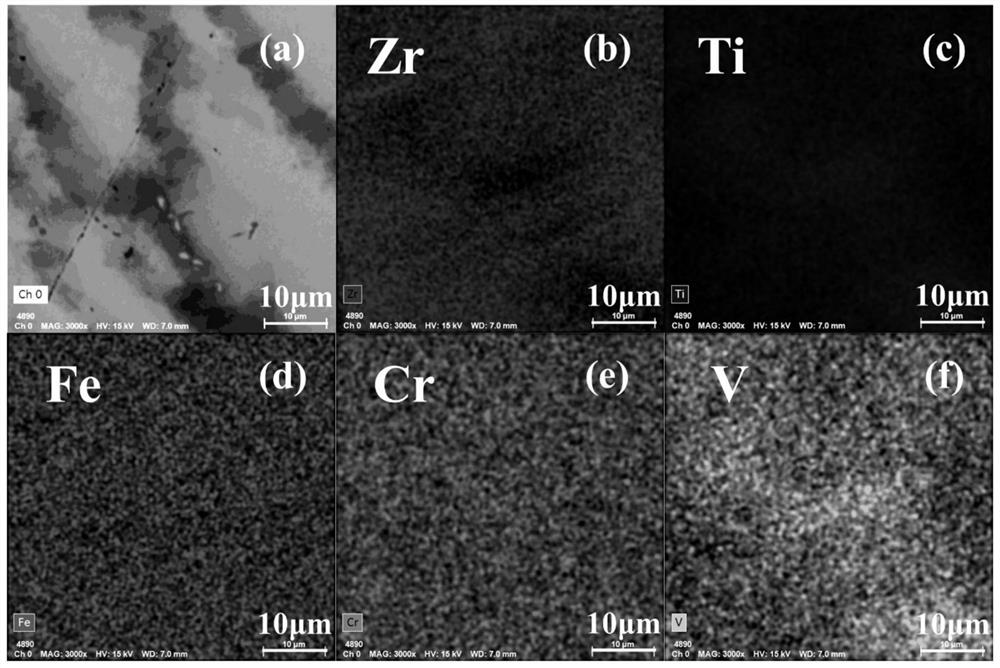

Embodiment 1

[0041] (1) Put 3.3865gZr, 0.7681gTi, 0.5538g Cr, 5.0342g Fe and 0.2714g V with a purity of more than 99.9% into the crucible of the electric arc melting furnace, cover the furnace cover, and vacuum the furnace chamber until the vacuum degree is 3×10 -3 Pa, filled with argon to a pressure of 0.06MPa, and melted in an arc higher than 1600°C. After that, the residual oxygen in the furnace chamber is absorbed by melting the pre-placed pure zirconium blocks in the furnace chamber by electric arc. In order to improve the uniformity, each sample was turned over and remelted 5 times, each melting time was about 30s, and 9.9950g ingot was obtained after cooling by a water-cooled copper mold for 15min. The theoretical composition of the alloy ingot is Zr 0.7 Ti 0.3 Fe 1.7 Cr 0.2 V 0.1 .

[0042] (2) Grinding the alloy ingot in step (1) with a grinder to remove surface scale. The alloy was then crushed into a powder state in a glove box, and screened with a 100-mesh sieve to obtai...

Embodiment 2~5

[0049] The alloy compositions and hydrogen storage thermodynamic properties of Examples 2-5 are shown in Table 1, and the preparation process is the same as that of Example 1.

[0050] Zr in table 1 embodiment 2-5 1-x Ti x Fe 1.7 Cr 0.2 V 0.1 Hydrogen Storage Thermodynamic Properties of (x=0,0.1,0.2,0.4) Alloys

[0051]

[0052]

[0053] *The plateau pressure values of the alloys at 298K and 333K are extrapolated from the van't Hoff equation.

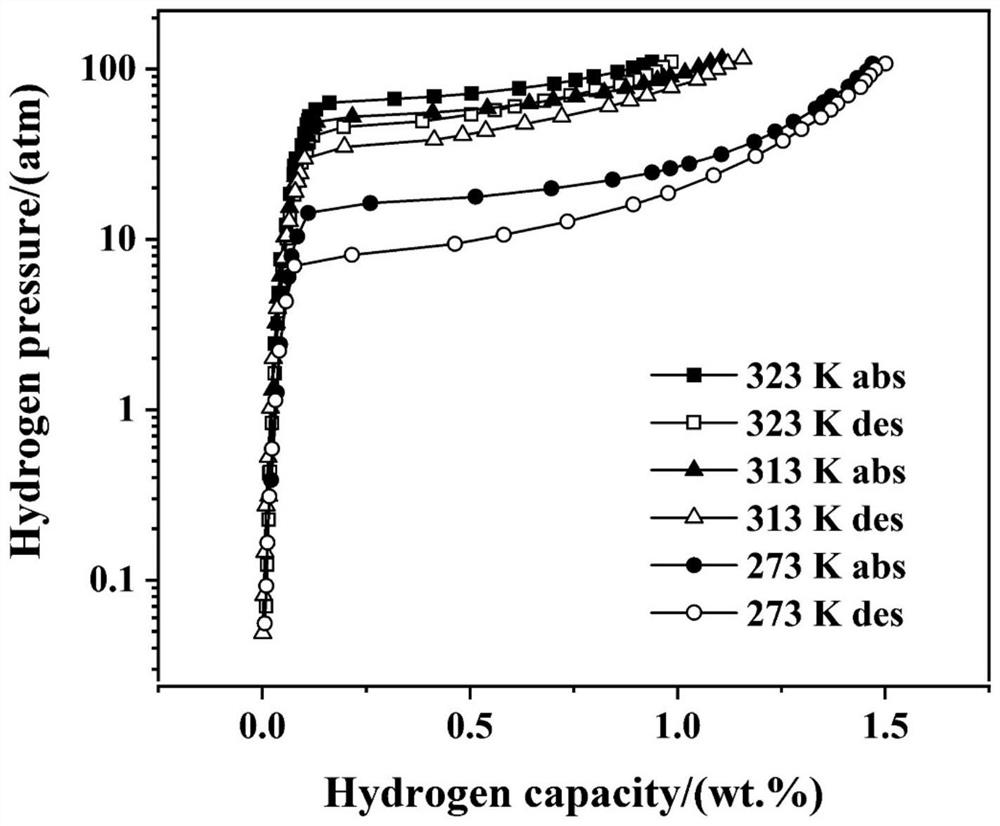

[0054] Figure 6(a), Figure 6(b), Figure 6(c), Figure 6(d) are Zr 1-x Ti x Fe 1.7 Cr 0.2 V 0.1 (x=0,0.1,0.2,0.4) alloy PCI curve, it can be observed that with the increase of Ti to Zr substitution, the hydrogen desorption plateau pressure of the alloy at the same temperature (273K) is significantly increased, and the hydrogen storage capacity is significantly reduced . In addition, the proportion of the α hydrogen solid solution region in the PCI curve decreases, and the proportion of the β hydride phase region increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com