Photoresist, display substrate and display panel

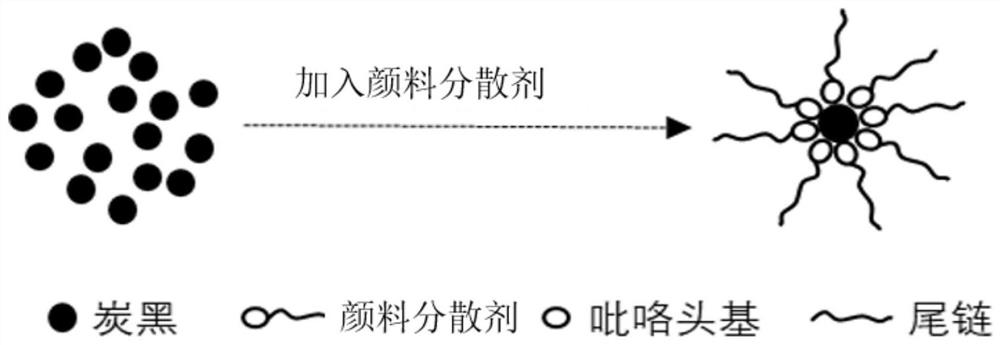

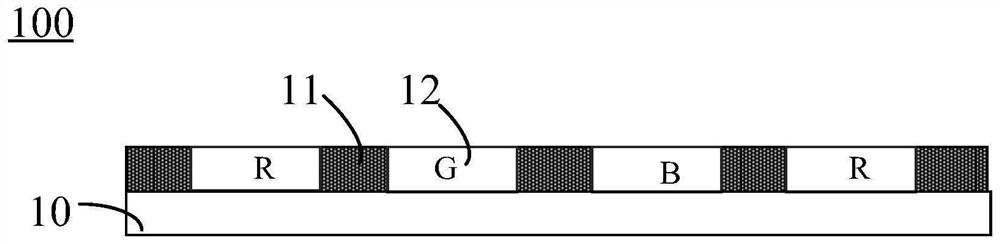

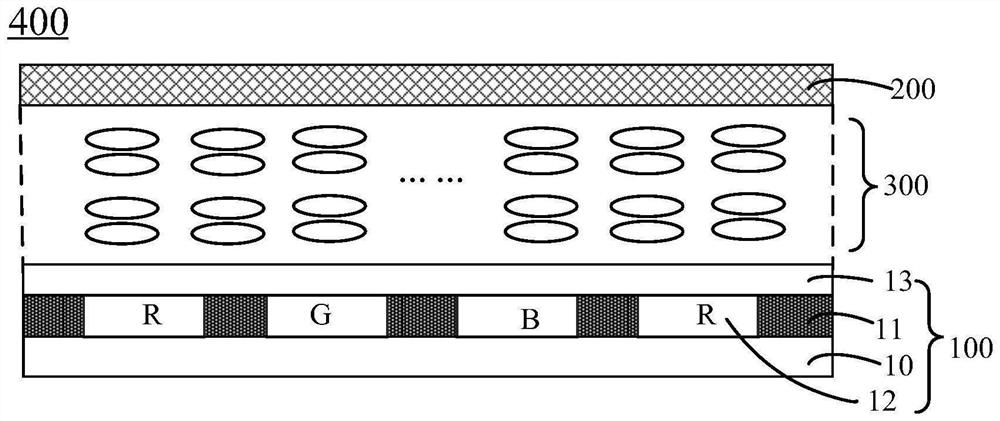

A display substrate and photoresist technology, applied in optics, optomechanical equipment, nonlinear optics, etc., can solve problems such as burrs on cured patterns and easy aggregation of black pigments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The embodiment of the present application also provides a method for preparing a photoresist, comprising the following steps:

[0063] Under no light irradiation, the alkali-soluble resin, photopolymerizable substance, black pigment, pigment dispersant, initiator and solvent are uniformly mixed to obtain the aforementioned photoresist.

[0064] The specific structure and content of the pigment dispersant in the photoresist, as well as the specific selection and optional content range of other raw materials are as described above in this application, and will not be repeated here. The preparation method of the photoresist has a simple and controllable process and is suitable for industrial production.

[0065] In some embodiments, the preparation process of the photoresist includes:

[0066] Under no-light irradiation, mix alkali-soluble resin, photopolymerizable substance, black pigment, pigment dispersant and a part of solvent, and disperse uniformly to obtain the fir...

Embodiment 1

[0094] A kind of photoresist for forming black matrix, this photoresist comprises each raw material of following mass percentage content:

[0095] Alkali-soluble resin (specific preparation method as described below): 8%;

[0096] Photopolymerizable monomers (specifically methacrylic acid and butyl methacrylate): 12%;

[0097] Oligomers (specifically oligomers of methacrylic acid and methyl methacrylate, with a molecular weight of about 1000): 2%;

[0098] Photoinitiator (specifically initiator 369): 2%;

[0099] Initiator dispersant (specifically 3,3-diphenylpropionic acid): 0.3%;

[0100] Black pigment (specifically, carbon black with a particle size of 20nm): 20%;

[0101] Pigment dispersant (its structural formula is shown in the aforementioned formula (i1), a=2): 0.2%;

[0102] Solvent (specifically, a mixture of propylene glycol methyl ether acetate, 3-methoxybutyl acetate, diethylene glycol methyl ethyl ether, and propylene glycol n-propyl ether, the mixing ratio is...

Embodiment 2

[0123] A photoresist for forming a black matrix, the difference between the photoresist and Example 1 is that the pigment dispersant used is pyrrole-1-propionic acid, its structural formula is as shown in the aforementioned formula (i2), a=2 .

[0124] The photoresist of Example 2 was observed by TEM, and no carbon black aggregation phenomenon was found; the BM produced by the photoresist did not appear burrs, and the OD value of the BM with a thickness of 1 μm was about 4.32, which was consistent with the same conditions. The OD value of the BM prepared from the photoresist without adding the pigment dispersant increased by about 5.36%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com