Multilayer-structure super-hydrophobic surface capable of resisting condensation failure under photo-thermal condition and preparation method of multilayer-structure super-hydrophobic surface

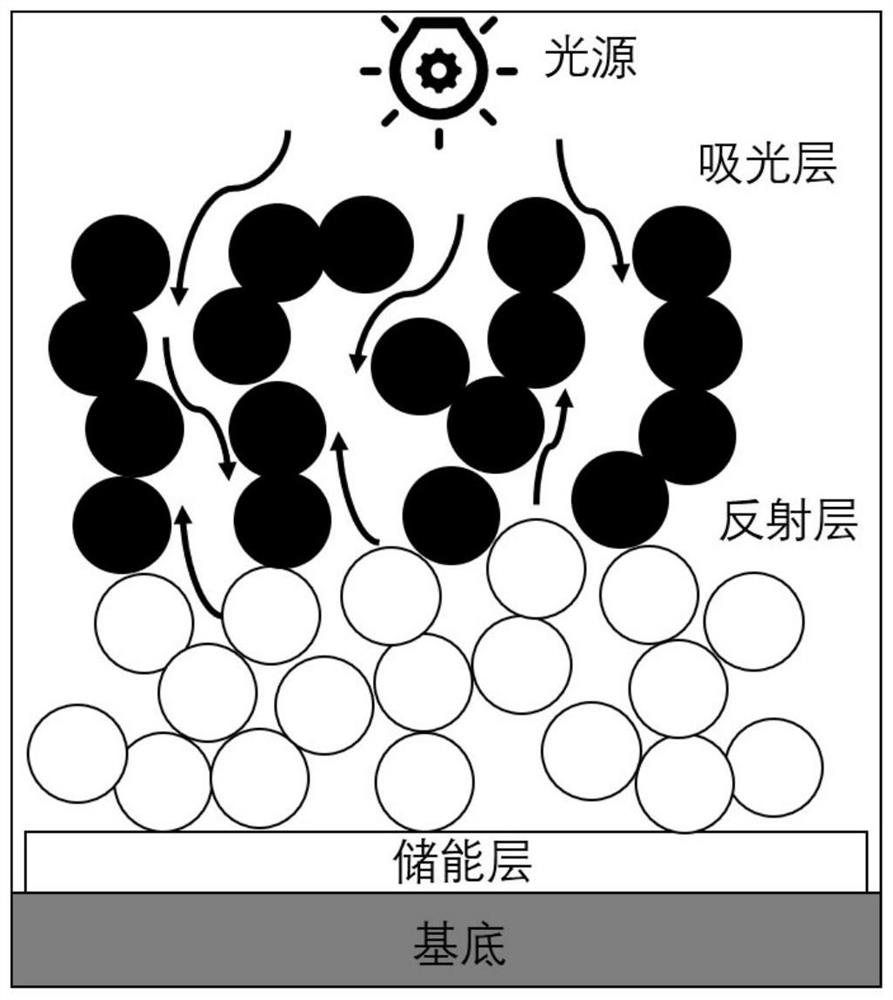

A super-hydrophobic surface and multi-layer structure technology, applied to special surfaces, devices for coating liquid on the surface, coatings, etc., to achieve strong light-harvesting performance, superior light-reflecting performance, and small gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a method for preparing a superhydrophobic surface with a multilayer structure capable of photothermal anti-condensation failure, including the following steps:

[0048] (1) Drop coating energy storage layer

[0049] Na 2 SO 4 10H 2 O was mixed with absolute ethanol, prepared into a suspension at a mass concentration of 500 mg / mL, and dripped with a plastic dropper. The suspension was covered with the entire silicon wafer and placed flat on the table. After standing at room temperature for 6 hours, the energy storage layer was obtained.

[0050] (2) drop coating reflective layer

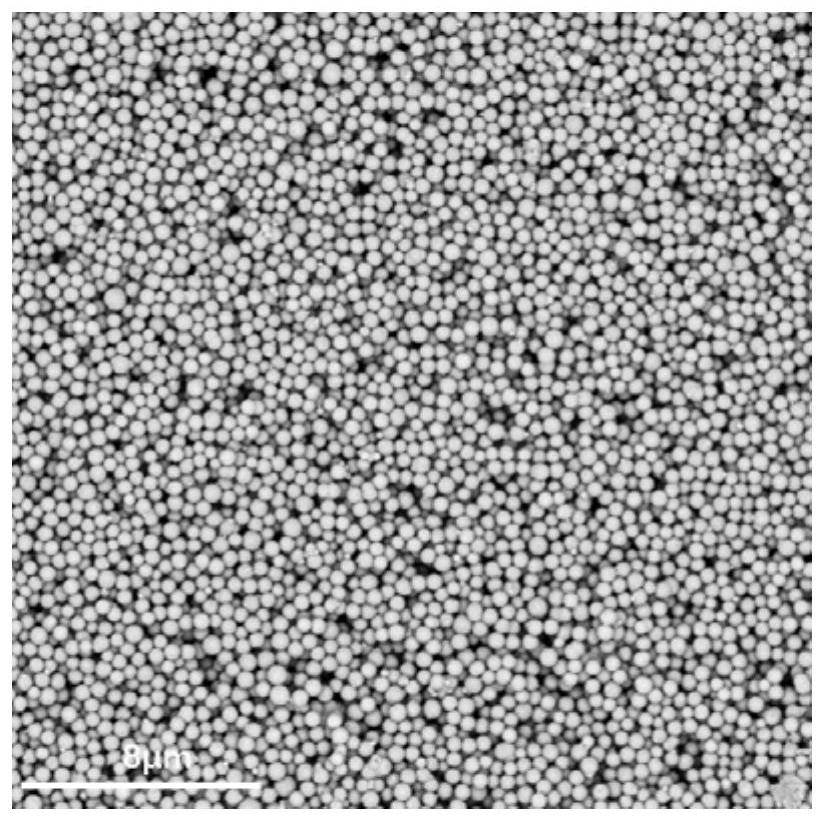

[0051] Mix solid silica spheres with a particle size of 300nm and absolute ethanol, prepare a suspension at a mass concentration of 30mg / mL, drop it with a plastic dropper, cover the entire energy storage layer with the suspension, and place it flat on the table. Place it at room temperature for 6h to obtain a white silicon dioxide reflective layer.

[0052] (3) Dr...

Embodiment 2

[0058] This embodiment provides a method for preparing a superhydrophobic surface with a multilayer structure capable of photothermal anti-condensation failure, including the following steps:

[0059] (1) Spraying the energy storage layer

[0060] Na 2 SO 4 10H 2 O was mixed with absolute ethanol, prepared as a suspension at a mass concentration of 400 mg / mL, and sprayed onto half the surface of the silicon wafer at a spray speed of 50 mL / min by a pneumatic spraying equipment to obtain an energy storage layer.

[0061] (2) Spray double reflective layer

[0062] Mix solid silica spheres with a particle size of 500nm and absolute ethanol, prepare a suspension at a mass concentration of 50mg / mL, and spray it onto the surface of the energy storage layer at a spray speed of 50mL / min using a pneumatic spraying equipment to obtain a layer Silica material surface. Then mix solid silica spheres with a particle size of 100nm and absolute ethanol, prepare a suspension at a mass conc...

Embodiment 3

[0069] This embodiment provides a method for preparing a superhydrophobic surface with a multilayer structure capable of photothermal anti-condensation failure, including the following steps:

[0070] (1) Drop coating energy storage layer

[0071] CaCl 2 ·6H 2 O was mixed with absolute ethanol, prepared into a suspension with a mass concentration of 200 mg / mL, and dripped with a plastic dropper. The suspension was covered with the entire silicon wafer and placed flat on the table. After standing at room temperature for 6 hours, the energy storage layer was obtained.

[0072] (2) Spray reflective layer

[0073] Mix solid silica spheres with a particle size of 300nm and absolute ethanol, prepare a suspension at a mass concentration of 30mg / mL, and spray it onto the surface of the energy storage layer at a spray speed of 50mL / min using a pneumatic spraying equipment to obtain a reflective layer surface.

[0074] (3) Spray light-absorbing layer

[0075] Mix carboxylated multi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com