Wedge plunger wave making device suitable for making high-order nonlinear waves

A wave-making device and nonlinear technology, applied in measurement devices, fluid dynamics tests, and testing of machine/structural components, etc., can solve the problem of low wave-making efficiency, waste of manpower and material resources, and reduction of the effective length of wave-making tanks, etc. problem, to achieve the effect of improving the quality of wave-making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

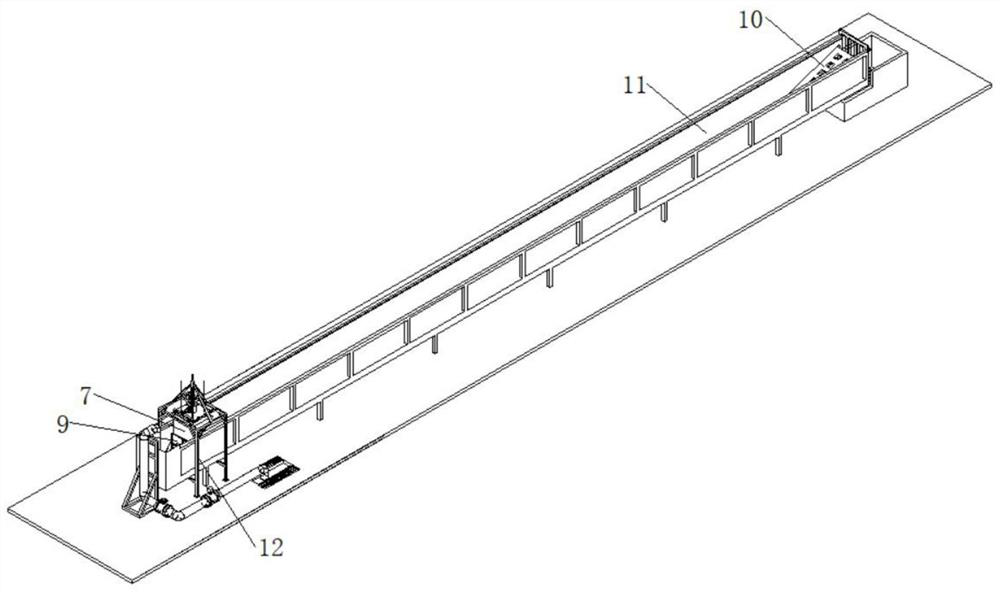

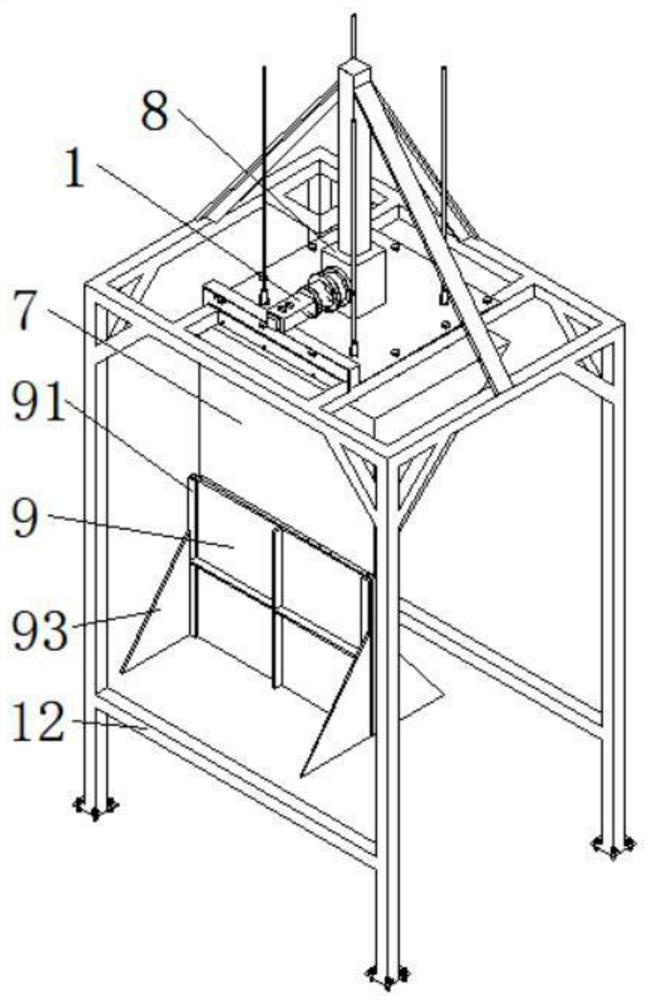

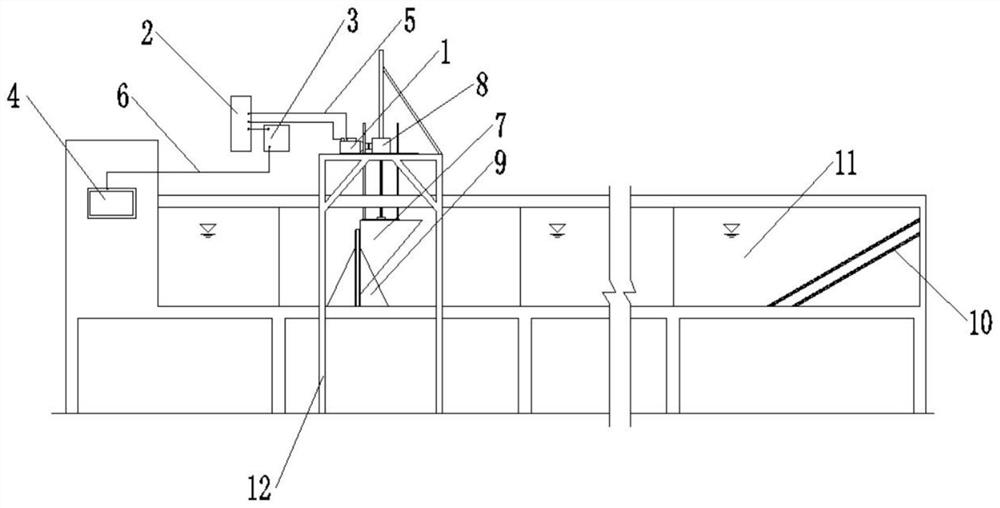

[0027] Such as Figure 1-10 As shown, the present invention provides a wedge plunger wave-making device suitable for manufacturing high-order nonlinear waves, including a servo system, a motion module 7, a wave-eliminating device 10, and a water tank 11. The servo system consists of a servo motor 1, a driver 2 , a controller 3 and a man-machine interface 4, and are connected with a power cable 5 and a data transmission line 6, and one side of the servo motor 1 is equipped with a transmission device 8 through a fixed bracket 12, and the bottom end of the transmission device 8 is connected with a motion Module 7, transmission device 8 comprises screw mandrel 81, head flange 82, gear box 83, first mounting plate 84, second mounting plate 88 and guide rail 85, first mounting plate 84 and second mounting plate 88 are arranged in parallel, And carry out fixed connection by guide rail 85 at the four corners, head flange 82 is installed on the top surface of the first mounting plate 8...

Embodiment 2

[0031] Further, the transmission device 8 adopts a bevel gear-ball screw lifting platform.

[0032] When the servo controller 3 controls the rotation of the servo motor 7, the motor shaft drives the bevel gear of the transmission device 8 to rotate, and at the same time makes the ball screw 81 do a vertical reciprocating linear motion. During the working process of the ball screw-bevel gear transmission 8, It has higher transmission efficiency and greatly reduces the power of the servo motor 1 .

[0033] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0035] Further, the motion module 7 is a wedge structure with a wedge angle of 45°-60°, and the two can be replaced with each other.

[0036] When the manufacturing target waves are linear waves, Stokes waves, and irregular waves, the wedge with a wedge angle of 45° is fixed on the flange of the transmission device with an M16 screw, such as Figure 9 As shown, the method of Example 1 is used to make waves; when the manufacturing target wave is a solitary wave, the wedge with a wedge angle of 60° is fixed on the flange of the transmission device with an M16 screw, as shown in Figure 10 As shown, the method of embodiment 1 is used to make waves.

[0037] Other structures of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com