Full-automatic high-flux homogenizer

A homogenizer, high-throughput technology, applied in chemical instruments and methods, dry solid materials, preparation of samples for testing, etc., can solve the problems of installation, disassembly, difficulty in replacement, slow replacement, etc. clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

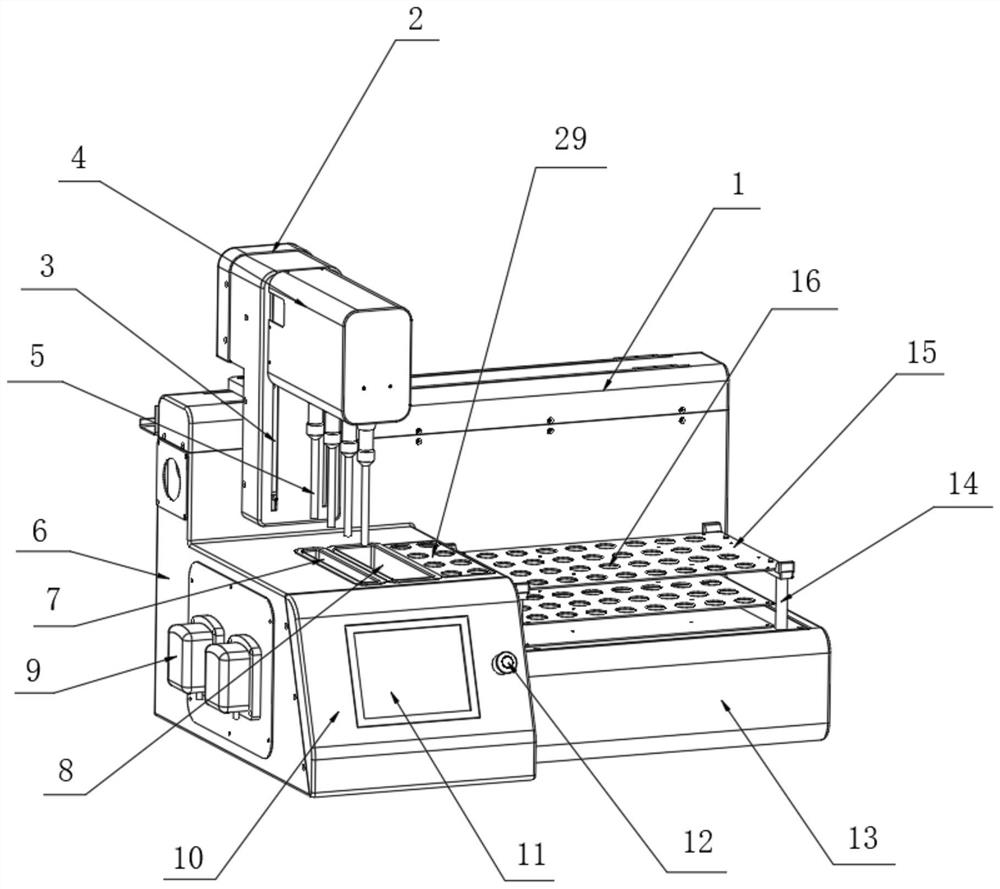

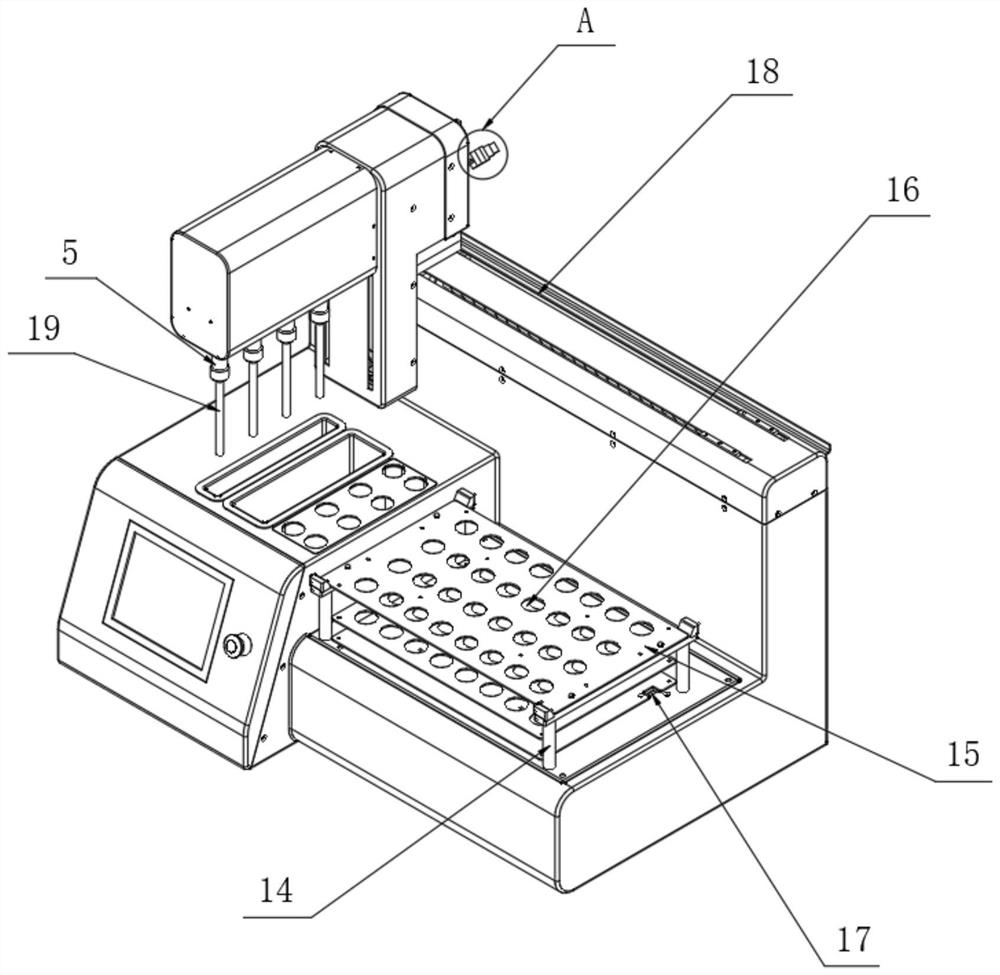

[0021] see Figure 1-4 , the present invention provides a technical solution: a fully automatic high-throughput homogenizer, including a homogenizer sliding table 1, a sliding connecting rod 2 is detachably installed on the top of one side of the homogenizing device sliding table 1, and the sliding connecting rod The top of one side of 2 is provided with a Z-axis screw slide rail 3, the top of one side of the sliding connecting rod 2 is detachably installed with a homogenizer controller 4, and the bottom end of the homogenizer controller 4 is detachably installed with a homogenizer head 5 A control base 6 is fixedly installed on one side of the homogenizer slide table 1, and a flow washing pool 7 is provided inside the control base 6, and an ultrasonic cleaning pool 8 is provided on one side of the flow washing pool 7, and an ultrasonic cleaning pool 8 is provided on one side of the ultrasonic cleaning pool 8. A custom cleaning pipe rack 29 is fixedly installed, a peristaltic ...

Embodiment 2

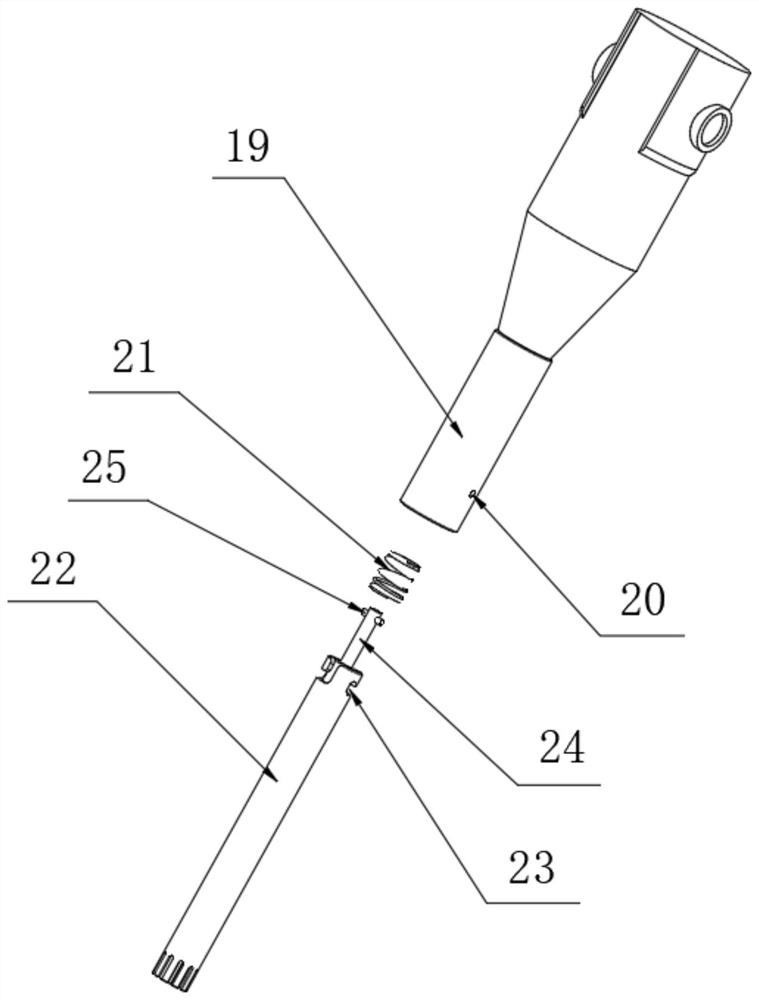

[0024] see Figure 1-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the surface of the quick-connect sleeve 19 is provided with a positioning pin 20, and the inside of the positioning pin 20 is detachably installed with a spring 21, and the quick-connect sleeve 19 One side is detachably equipped with homogenizing rod 22, and the top of one side of homogenizing rod 22 is provided with homogenizing cutter head introduction groove 23, and the inside of homogenizing cutter head introducing groove 23 is detachably installed with sleeve rod 24, sleeve rod The top on one side of 24 is fixedly equipped with a buckle rod 25, and the connection relationship between the homogenizing cutter head introduction groove 23 and the positioning pin 20 is movable clamping connection, and the back side of the sliding connecting rod 2 is detachably equipped with a circuit box 26, and the circuit box 26- A circuit connector 27 is detachably installed o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap