Greenhouse container and working method

A container and greenhouse technology, applied in greenhouse cultivation, botanical equipment and methods, agricultural machinery and equipment, etc., can solve the problems of high energy consumption and large electric energy demand, achieve low cost, reduce operating time and power, and facilitate installation. maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

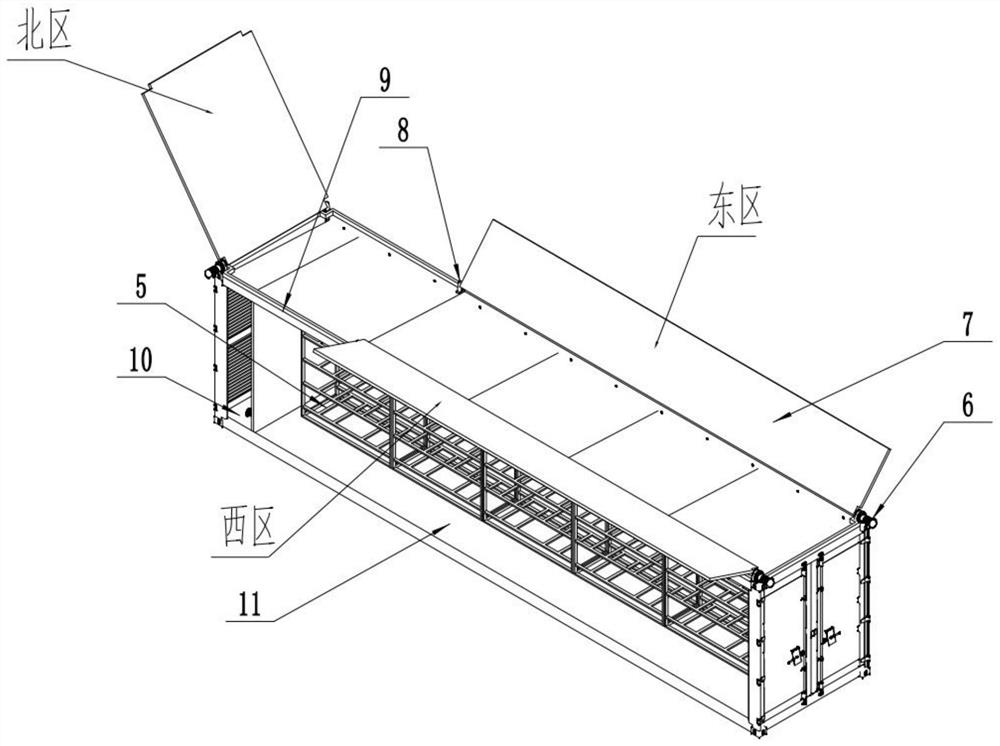

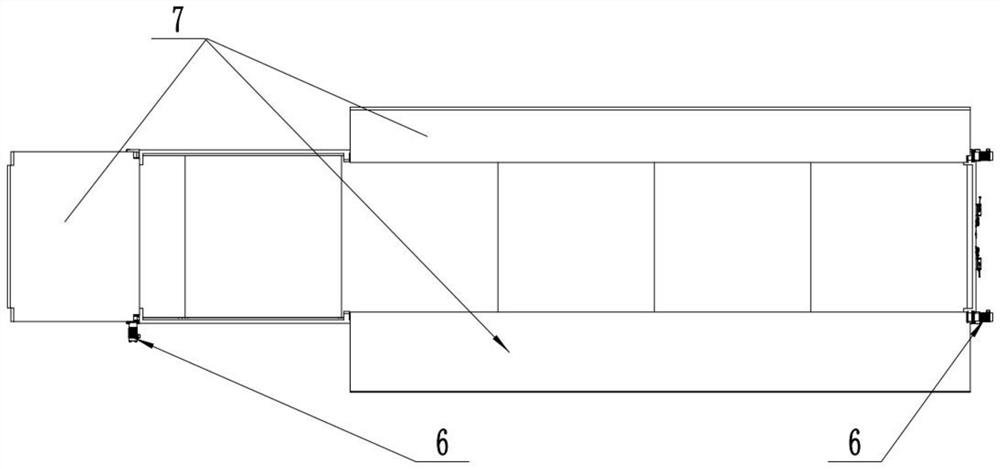

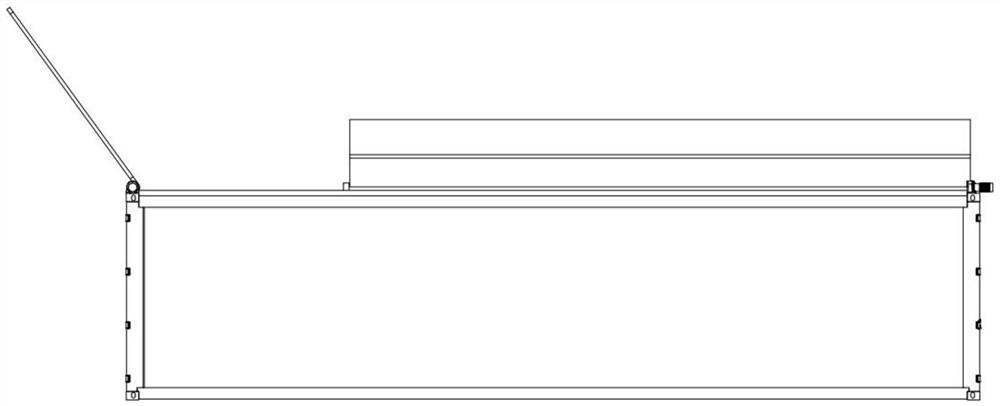

[0062] Such as Figure 1-30 As shown, the present embodiment provides a greenhouse container, comprising:

[0063] Box 1, the box 1 is divided into two independent spaces, the left side is the control power distribution room 10, the right side is the working room 11, the working room 11 is a relatively closed space, and the control power distribution room 10 is placed with a precision air conditioner 2. The control distribution box 3, the air pump 4, and the rack 5 are placed in the studio 11;

[0064] Glass window 28, the top of described casing 1 is equipped with multi-layer vacuum glass window 28;

[0065] Double-sided reflectors 7 , three double-sided reflectors 7 are rotatably installed on the top of the box body 1 , and the three double-sided reflectors 7 are respectively located on three sides of the glass window 28 .

[0066] In this embodiment, the box body 1 adopts a 40HQ standard container frame structure, with a length of 12.192 meters, a width of 2.438 meters, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com